Reverse recoil brake design method

A brake and anti-recoil technology, which is applied in the direction of the muzzle attachment, etc., can solve the problems of no use value for moving point targets, limited braking ability, and poor performance of the brake, so as to achieve a natural balance and shorten the overall The effect of gun length and lowering the height of the line of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

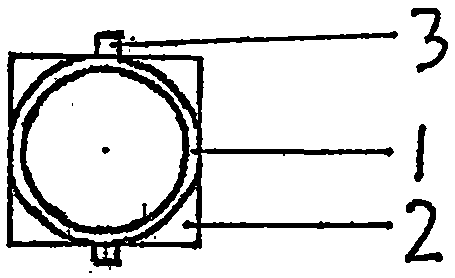

[0010] exist figure 1 Middle: 1 is the interface barrel, 2 is the interface plate, and 3 is the reinforcement plate.

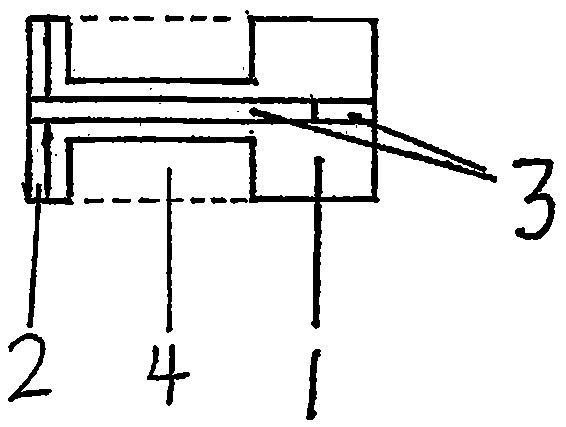

[0011] exist figure 2 Middle: 1 is the interface barrel, 2 is the interface plate, 3 is the reinforcement plate, and 4 is the horizontal outlet. According to the difference of the rate of fire of the matching guns, the length of the horizontal outlet can be adjusted to 1-3 times of the caliber of the gun (the matching drawing in this book is set as 1 time), so the interface tube and its supporting reinforcement plate, the horizontal outlet tube and the The connecting rod should also be lengthened accordingly.

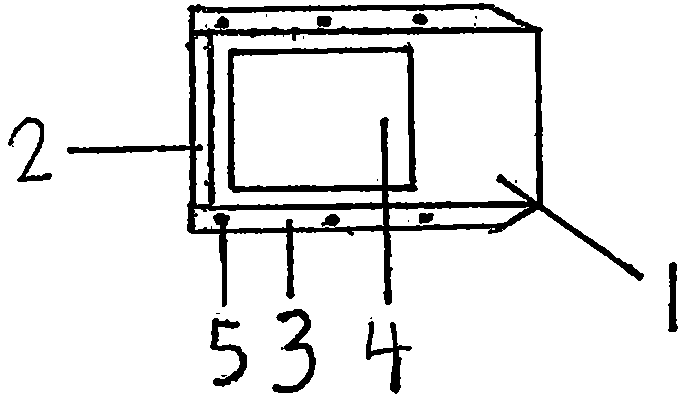

[0012] exist image 3 Middle: 1 is the interface barrel, 2 is the interface plate, 3 is the reinforcement plate, 4 is the horizontal outlet, and 5 is the screw socket.

[0013] exist Figure 4 Middle: 6 is the outlet tube, 7 is the foot.

[0014] exist Figure 5 Middle: 4 is the horizontal outlet, 5 is the screw socket, 6 is the outlet cylinder,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com