Lever system for force transmission

A lever and force transmission technology, used in grain handling and other directions to achieve the effect of good proximity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

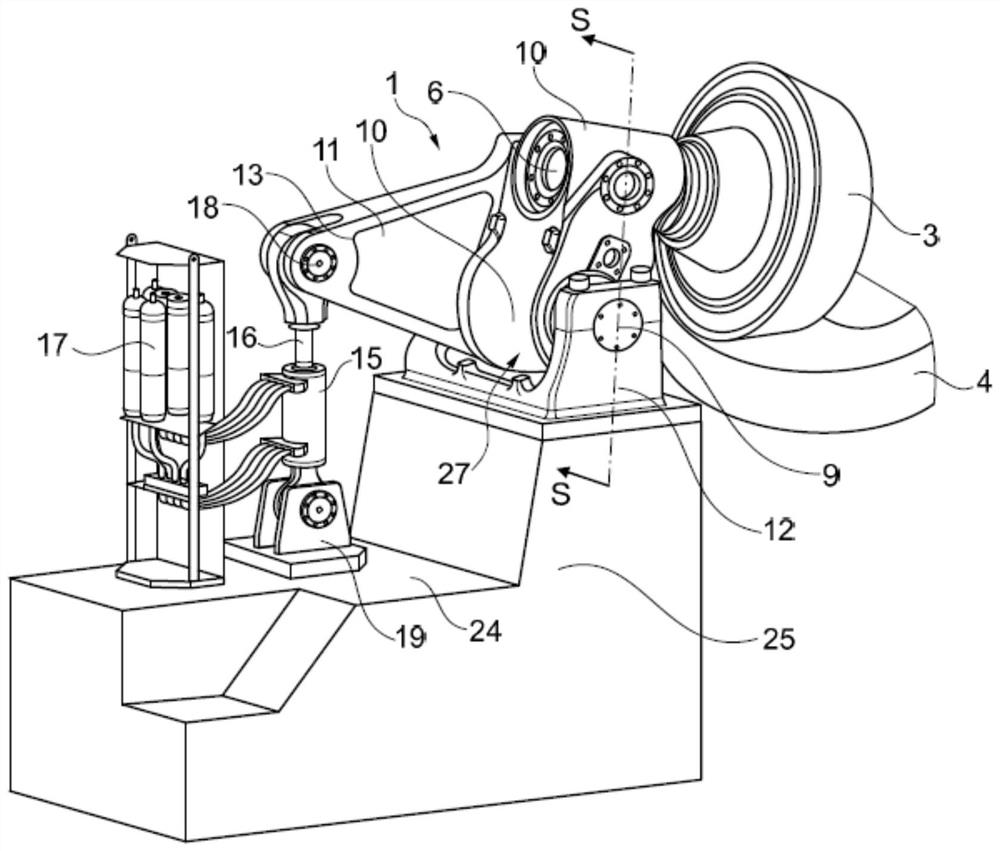

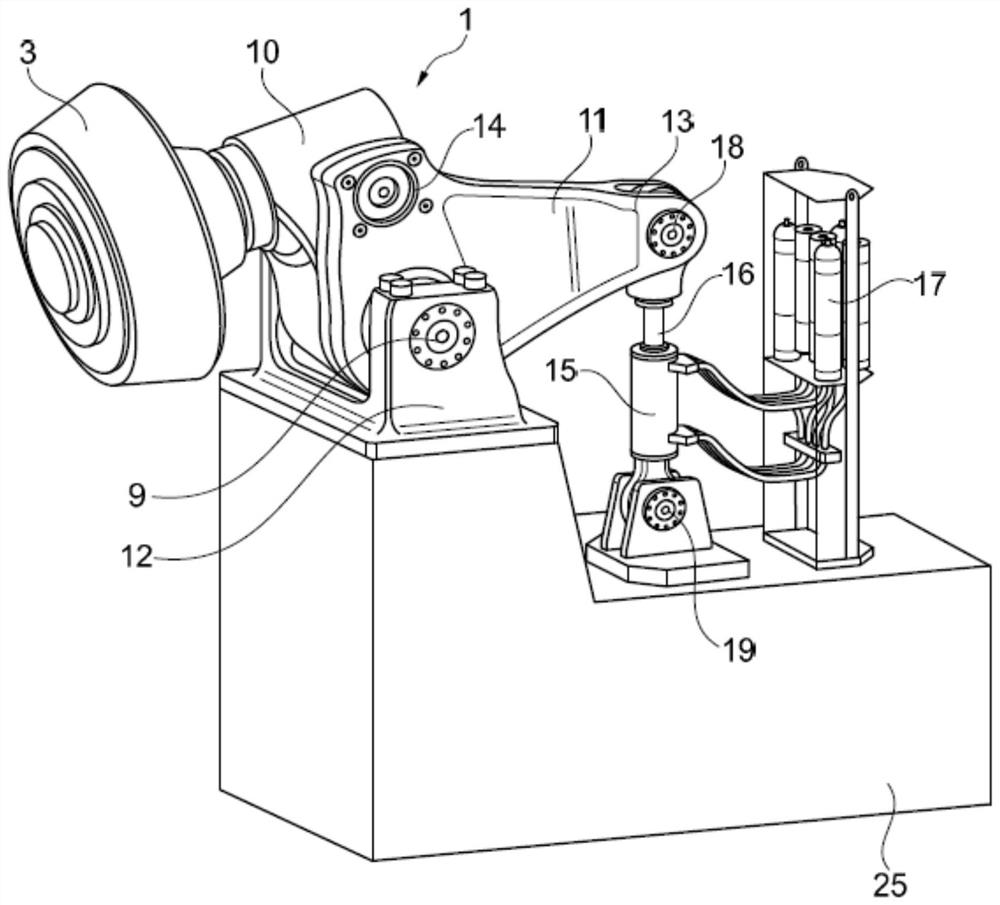

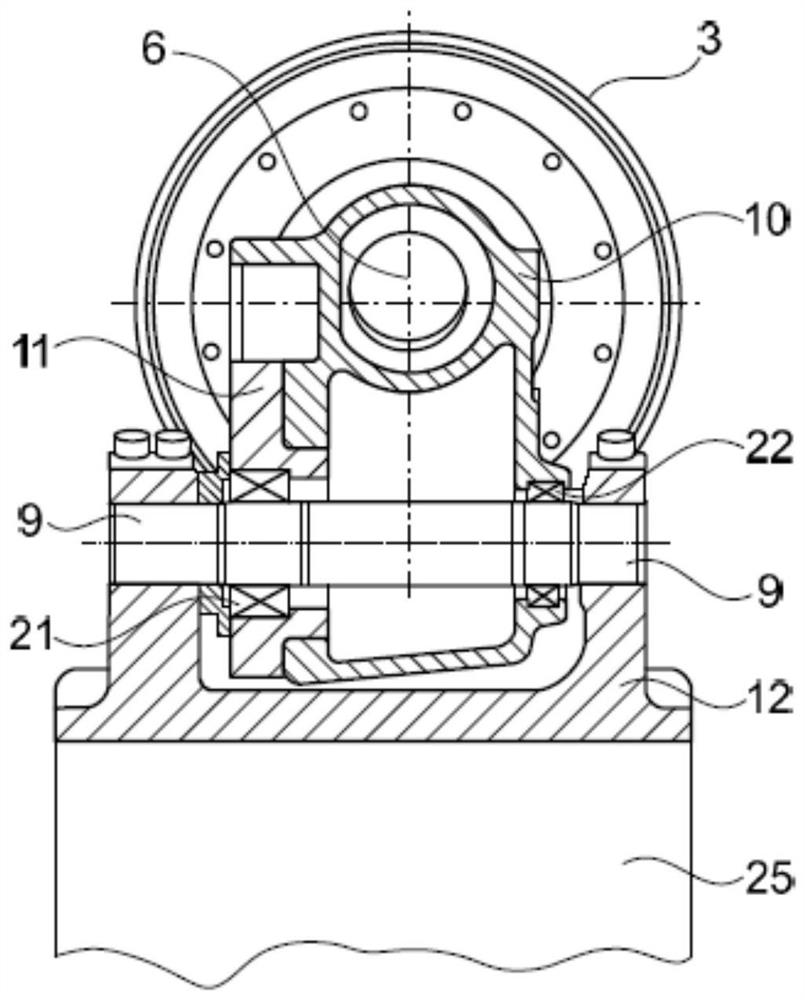

[0035] exist figure 1 The lever system 1 according to the invention is schematically shown in perspective in the direction of the corresponding grinding table 4 . The conical grinding roller 3 rolls on the grinding material to be comminuted in a non-positive and frictional manner during operation and is guided by its roller shaft 6 located in the central rocker 10 .

[0036] The central rocker 10 is arranged via the rocker shaft 9 in a U-shaped bearing block 12 , which in this example is fixed on a stepped concrete base 25 .

[0037]in accordance with figure 2 In a side perspective view of the lever system 1 of the present invention, the side rods 11 located in the area to the left of the central rocker 10 are firmly connected by means of flange-like fasteners 14, wherein the side rods 11 are supported on the lower part of the rocker shaft 9 in the area.

[0038] The side bars 11 having an approximately triangular or L-shaped design face with their L-shaped long sides in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com