Guimo brick for cement rotary kiln and preparation method of Guimo brick

A cement rotary kiln and silicon molybdenum brick technology, which is applied in the field of refractory materials, can solve the problems of temperature rise, material flow increase, self-heaviness, etc., and achieve the effects of avoiding high temperature, ensuring practical life, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

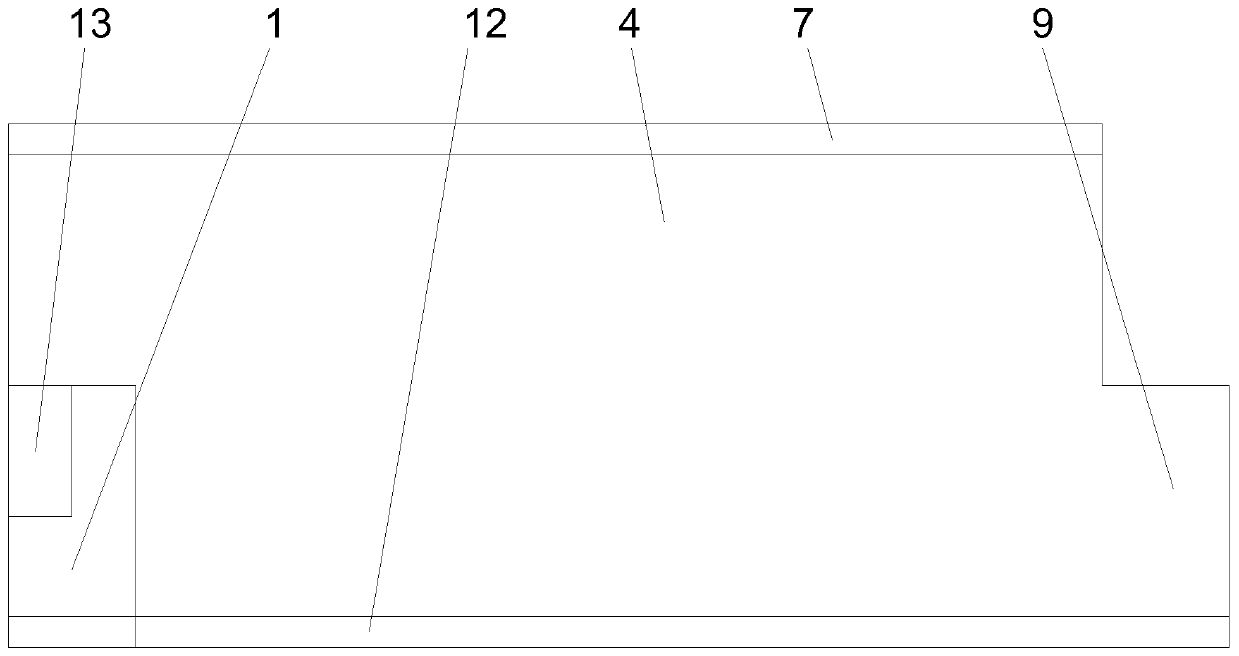

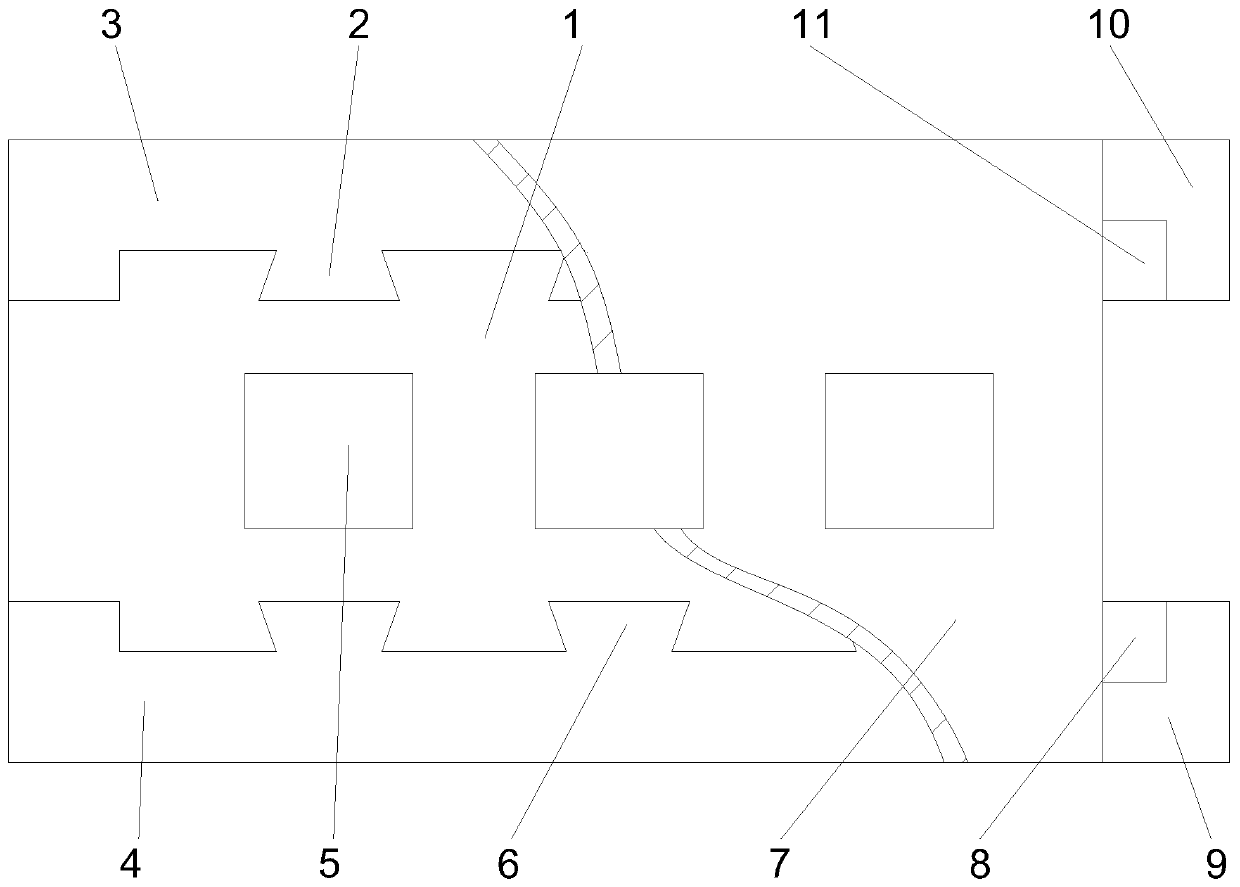

Image

Examples

preparation example Construction

[0033] A preparation method for silica brick for cement rotary kiln, comprising the following steps:

[0034] Bauxite, white corundum, silicon oxynitride, α-Al 2 o 3 Micropowder, metal silicon powder, antioxidants, additives and binders, spare;

[0035] Grind bauxite into fine powder and classify it into three kinds of granular raw materials with different particle sizes of 5-3mm, 3-1mm and 1-0mm, and set aside; grind white corundum into 200 mesh fine powder, set aside; grind silicon oxynitride into 320 mesh fine powder, spare;

[0036]According to weight percentage: 15-20% of 5-3mm bauxite, 20-25% of 3-1mm bauxite, 15-20% of 1-0mm bauxite, 5-15% of 200 mesh white corundum, oxynitrided Silicon 5~20%, α-Al 2 o 3 2-10% of fine powder, 1-3% of antioxidant, 1-10% of additives, add the above raw materials into the mixer, stir for 3-5 minutes to obtain a dry mix, and then add a binder with a weight percentage of 3-5% of the dry mix, Then stir for 10 minutes to obtain the first...

Embodiment 1

[0041] A preparation method for silica brick for cement rotary kiln, comprising the following steps:

[0042] Bauxite, white corundum, silicon oxynitride, α-Al 2 o 3 Micropowder, metal silicon powder, antioxidants, additives and binders, spare;

[0043] Al of the bauxite 2 o 3 Content ≥ 88%; Al of the white corundum 2 o 3 Content ≥ 99%; silicon oxynitride: Si 2 N 2 O≥88%, metal silicon powder, Si≥90%

[0044] Grind bauxite into fine powder and classify it into three kinds of granular raw materials with different particle sizes of 5-3mm, 3-1mm and 1-0mm, and set aside; grind white corundum into 200 mesh fine powder, set aside; grind silicon oxynitride into 320 mesh fine powder, spare;

[0045] According to weight percentage: 15% of 5-3mm alumina, 25% of 3-1mm alumina, 20% of 1-0mm alumina, 10% of 200 mesh white corundum, 15% of silicon oxynitride, α-Al 2 o 3 4% micro powder, 2% antioxidant, 9% additives, add the above raw materials into the mixer, stir for 3-5 minute...

Embodiment 2

[0050] A preparation method for silica brick for cement rotary kiln, comprising the following steps:

[0051] Bauxite, white corundum, silicon oxynitride, α-Al 2 o 3 Micropowder, metal silicon powder, antioxidants, additives and binders, spare;

[0052] Al of the bauxite 2 o 3 Content ≥ 88%; Al of the white corundum 2 o 3 Content ≥ 99%; silicon oxynitride: Si 2 N 2 O≥90%, metal silicon powder, Si≥88%

[0053] Grind bauxite into fine powder and classify it into three kinds of granular raw materials with different particle sizes of 5-3mm, 3-1mm and 1-0mm, and set aside; grind white corundum into 200 mesh fine powder, set aside; grind silicon oxynitride into 320 mesh fine powder, spare;

[0054] According to weight percentage: 20% of 5-3mm alumina, 25% of 3-1mm alumina, 15% of 1-0mm alumina, 8% of 200 mesh white corundum, 16% of silicon oxynitride, α-Al 2 o 3 5% micro powder, 3% antioxidant, 8% additives, put the above raw materials into the mixer, stir for 3-5 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com