Masonry engineering construction process

A technology of engineering construction and technology, applied in the direction of architecture, building components, building structures, etc., can solve the problems of poor overall strength of the wall, difficulty in ensuring the thickness of concrete, and difficulty in ensuring the quality of wall masonry, so as to achieve firm splicing and prevent The effect of cracking and toppling and tight masonry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings.

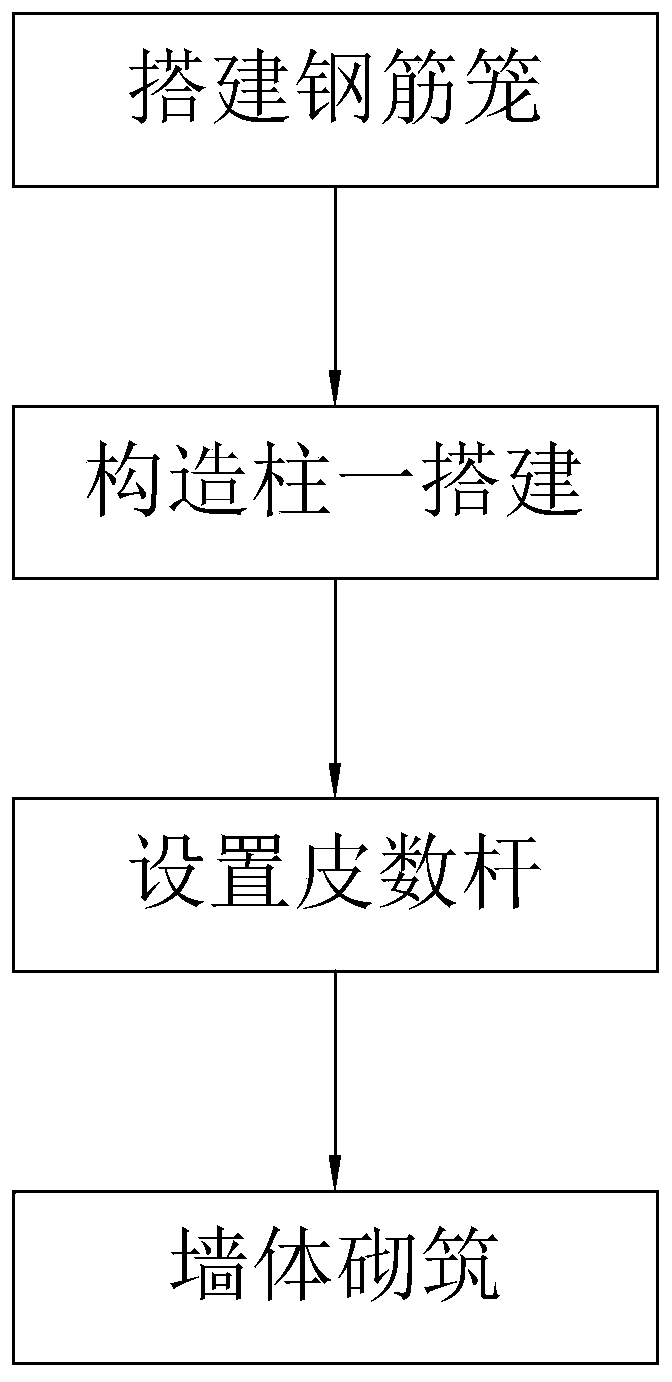

[0049] refer to figure 1 , is a kind of masonry construction technique disclosed by the present invention, comprising the following steps:

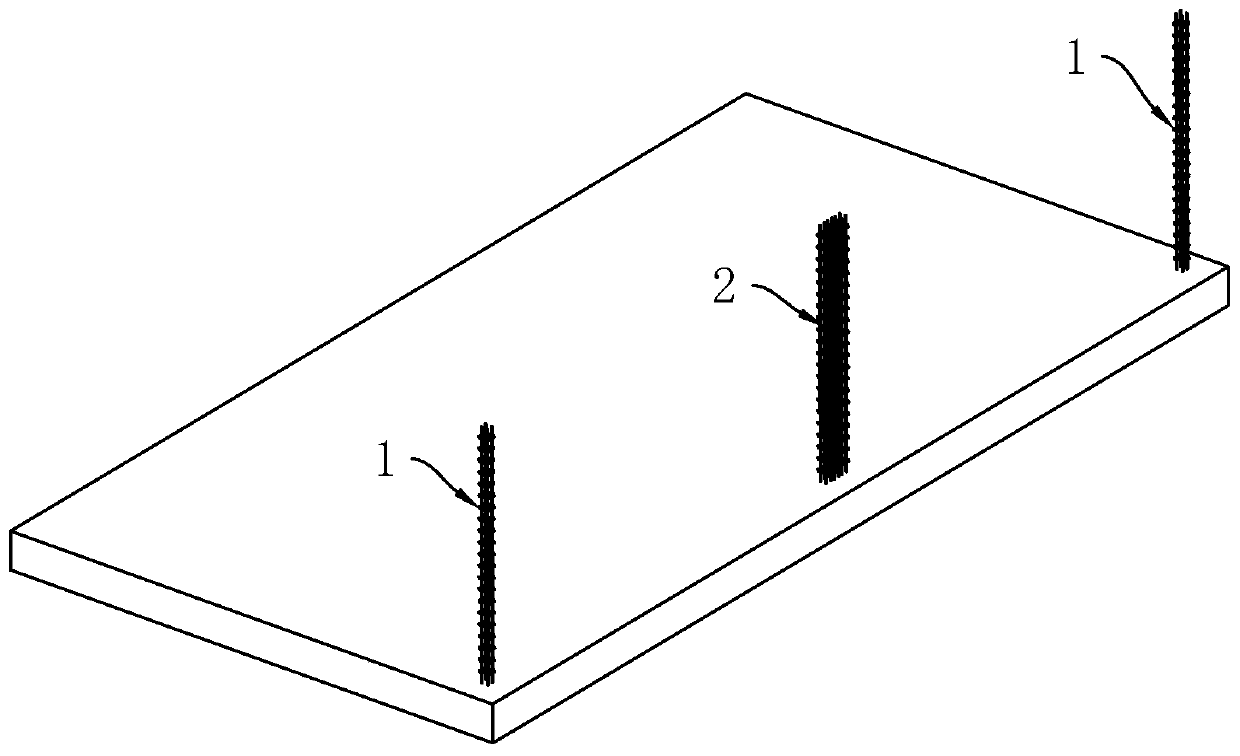

[0050] refer to figure 2 , step 1, build a reinforcement cage, set up a reinforcement cage 1 vertically at the corner position of the wall to be built, so that the lower end of the reinforcement cage 1 is fixedly connected with the steel bars in the base, and the walls to be built on each side The middle part all builds the reinforcement cage two 2 that vertically arranges, and the lower end of reinforcement cage two 2 is fixedly connected with the reinforcing bar in the base;

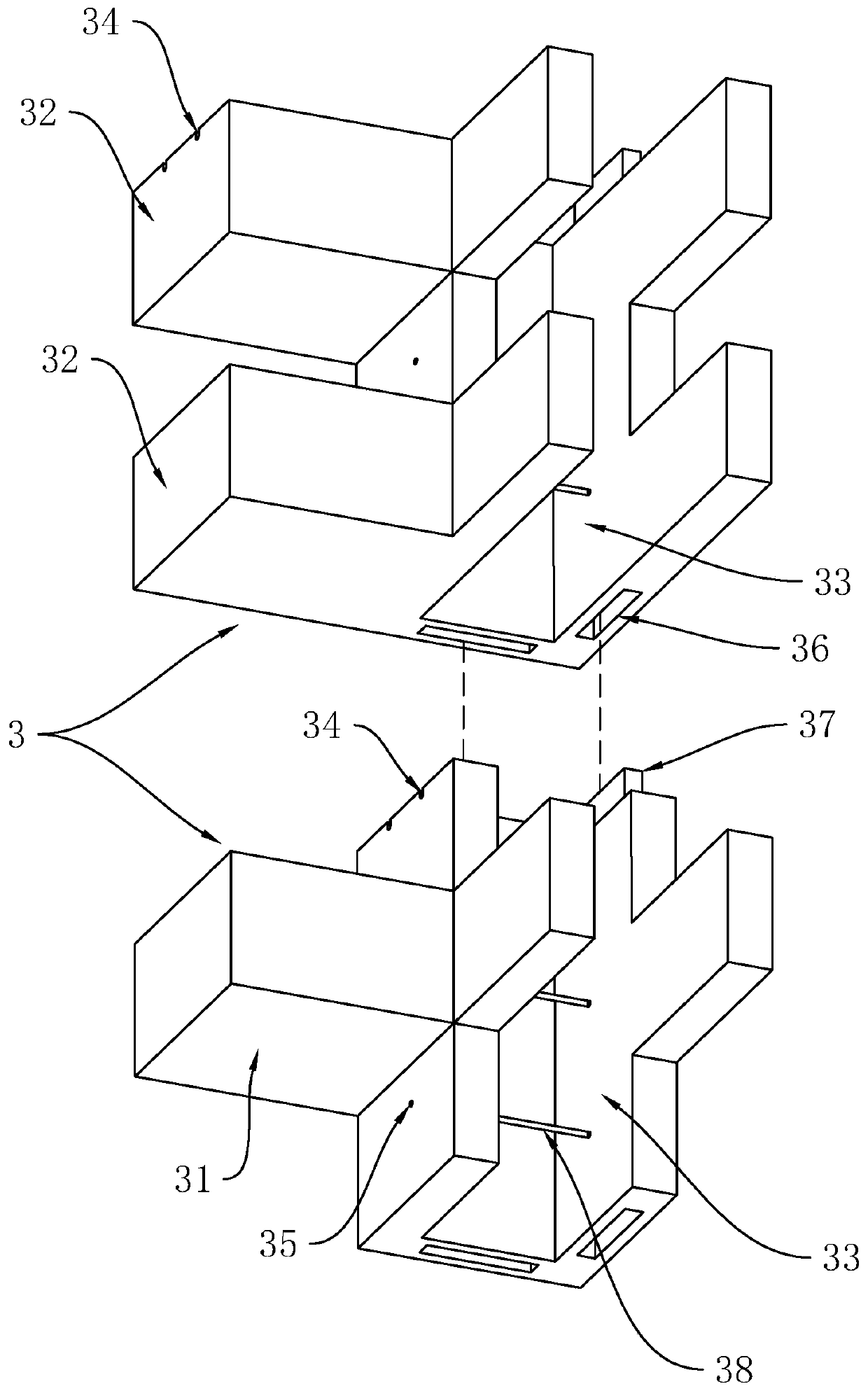

[0051] refer to figure 2 and image 3 , step 2, construction column 1 construction

[0052] a. As soon as the structural column is formed, select the concrete construction mold 3 in advance. The construction mold 3 includes template one an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com