Method for assembling iron tower through high-voltage power transmission lines

A technology for high-voltage transmission lines and iron towers, which is applied in the processing of towers, building materials, and building types, and can solve problems such as slow construction speed, difficult high-altitude operations, and difficult equipment erection operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Two light-duty aluminum alloy poles are used, and the top is connected with a steel rope as a sealing rope. On the outside of the two poles, four steel ropes are used to hold the pole at 30 degrees and the ground at less than 60 degrees. The ground anchor pile is fixed on the wire, and then a double-drum motorized winch mill is used to lift the vertical tower with two sets of wire ropes.

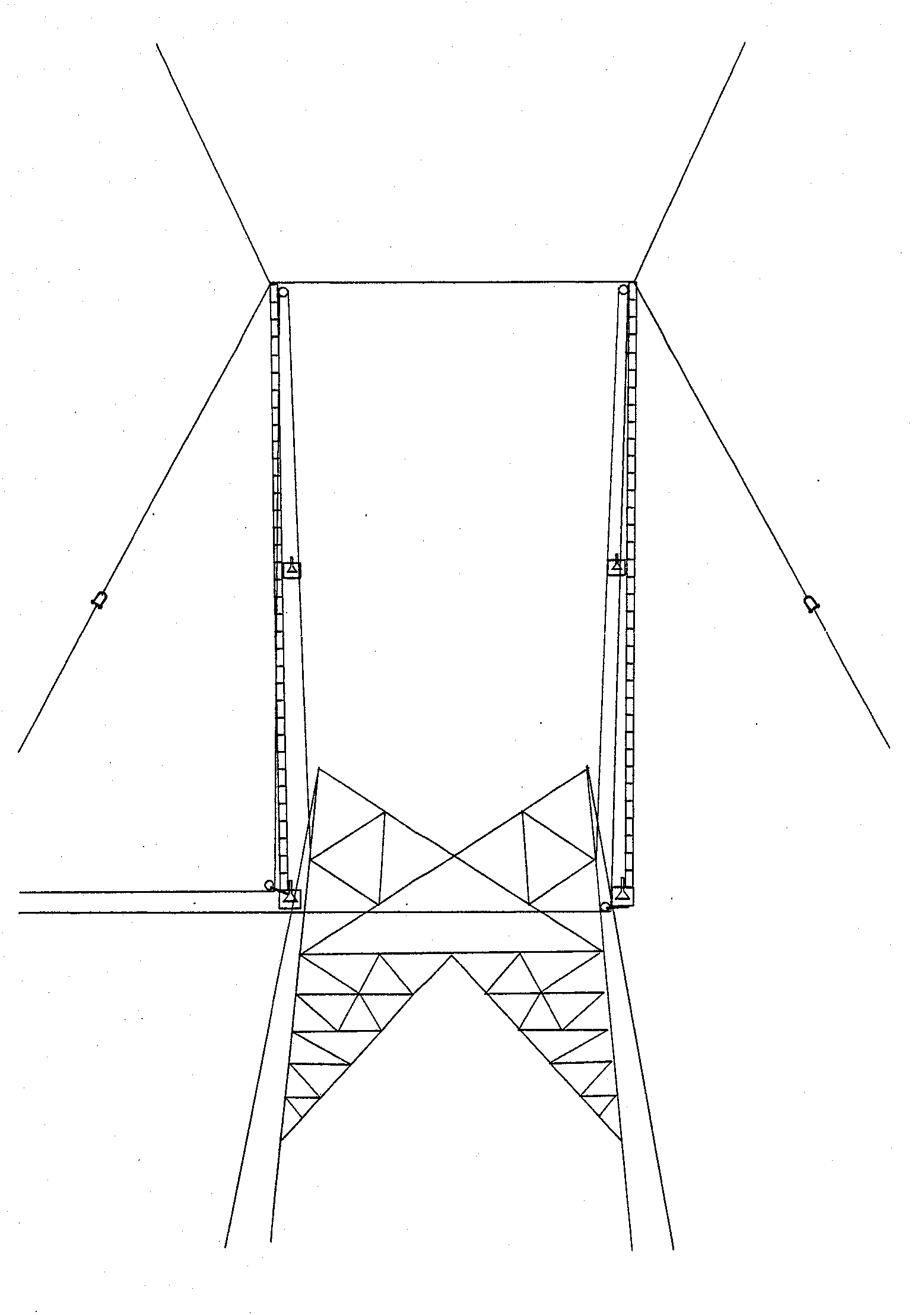

[0050] Such as figure 1 As shown, taking the hoisting of the whole section of the small tower as an example, first, the bottom section of the tower is bulked on the ground according to the traditional method, and then the two poles are erected on the second main material of the bottom section of the tower, and the top of the two poles is connected with a sealing rope. And two temporary stay wires are fixed on the ground anchor pile wires respectively, and the motorized winch is fixed in an appropriate position. The two pulleys are respectively installed at the bottom of the main mater...

Embodiment 2

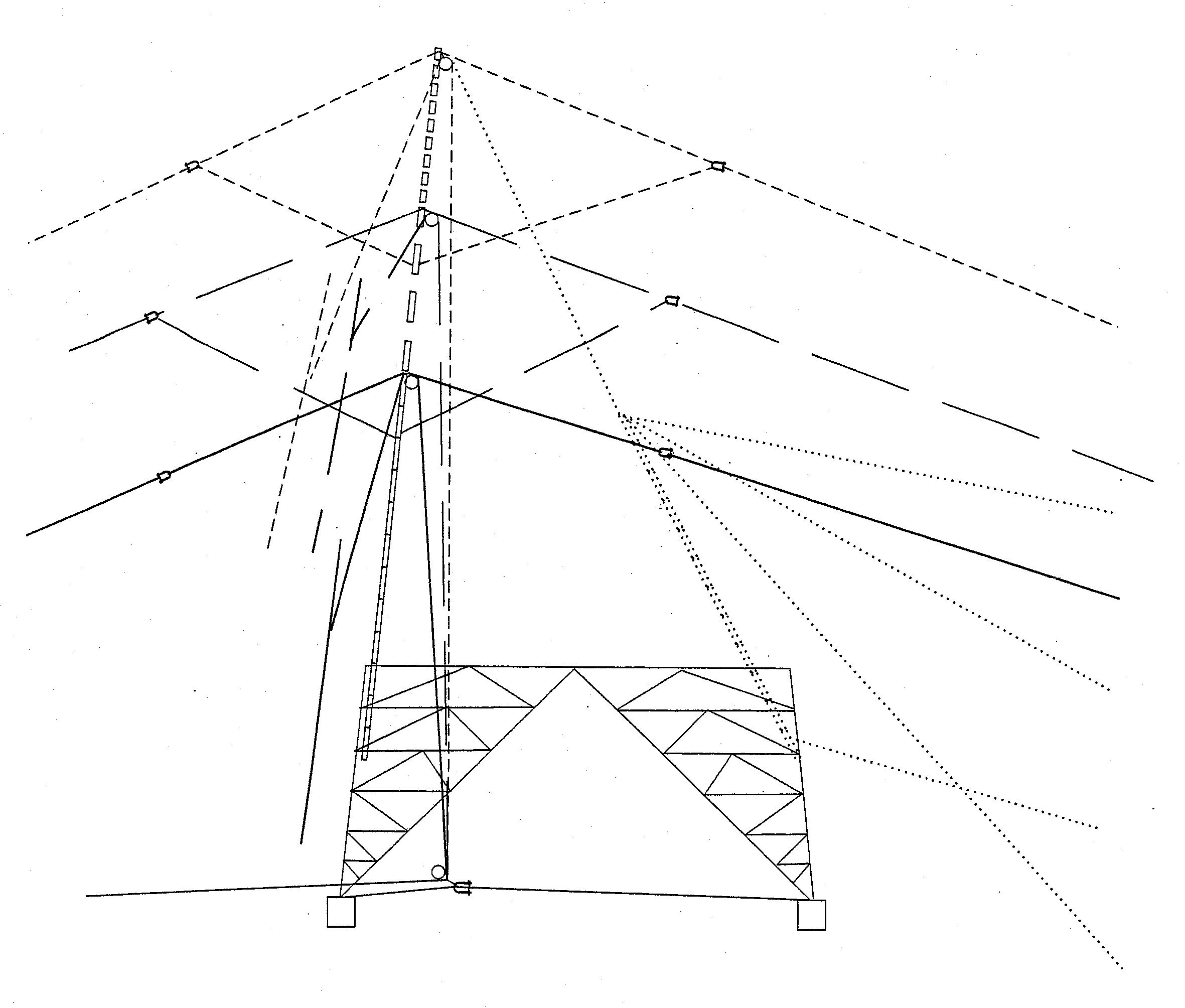

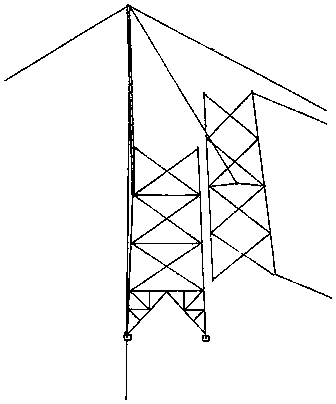

[0054] Such as Figure 7 to Figure 13 As shown, take the example of a single twisting mill and single pole with 4 landings and 8 branch pulls inside and outside, high point lifting and low point positioning, and changing to a large vertical tower. Such as Figure 1 to Figure 7 As shown, lifting the small tower: still use the original method of pulling the pole outside. Hoisting of medium-sized towers: In the bottom section, a single pole is placed in the ABCD four foundations of the tower, and the 4 external pulls are generally two along the line and two vertical lines, and the anchor piles are fixed at less than 60 degrees to the ground. According to the hoisting load capacity of the tools and equipment, hoist the two large sides in sections and complete the two sides in bulk, (or a whole section in bulk on the ground) lift the pole on the inner side of the D foot with spikes, tilt slightly to the A side, and lift it up in sections After the second segment, use the 4 upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com