Disadvantages: waste of material, medium efficiency, tool interference, especially serious in large and complex structures

Disadvantages: high investment threshold, long process cycle, large temperature changes,

phase transition, large stress,

large deformation, low overall precision, especially in the case of large and complex structures

However, as mentioned above, it can be seen that material subtraction and equal material all involve the surface of the overall material, while 3D printing involves the interior of the material,

cutting the interior into a surface that can be printed, which is much larger than the original surface area, so , at the same movement speed, the efficiency of 3D printing is much lower than the first two methods

Disadvantages: very low efficiency

In order to solve the problem of large-scale material

powder, the original mechanical structure design and process of the SLS process will become very complicated, the total cost of materials is high, and the

energy consumption will be very large.

[0015] The power of the

laser used in the SLS process is closely related to the molding speed. The maximum power is generally between 0.4kw--1kw. According to the principle of proportional amplification, the volume of the product is enlarged by 1000 times. Theoretically, the maximum power of the SLS process is also enlarged by 1000 times. , otherwise it is equivalent to using a small

light spot to describe a picture that has been enlarged by a thousand times, and the efficiency will be unacceptably low, or the maximum power of the matching

laser needs to be 400kw to 1000kw. According to the current

laser technology, the commonly used power is in the Below 6kw, 400kw may only be realized in the military field, so the large-scale SLS process is currently difficult to achieve

[0016] The printing layer height of SLS is also limited, because its principle is to sinter or melt the

powder to form a

solid state by using the focal spot of laser focus to generate high temperature, and heat conduction spontaneously diffuses to the surrounding

powder. If you want to have a deeper

Sintering thickness (layer height), thermal

diffusion will lead to uncontrollable sintered line edges

Therefore, in terms of technical principles, economics, and practicality, it is not suitable for large-scale

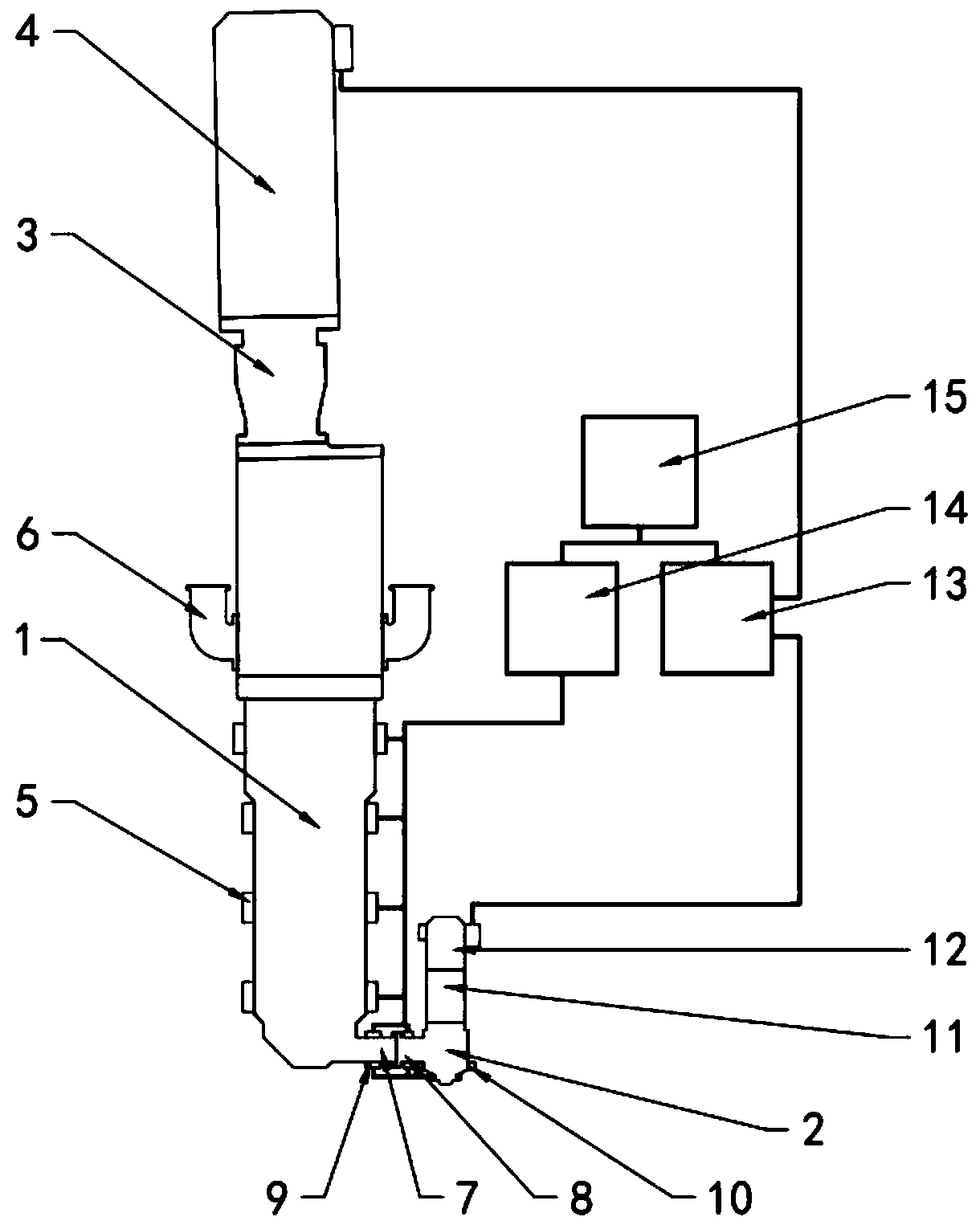

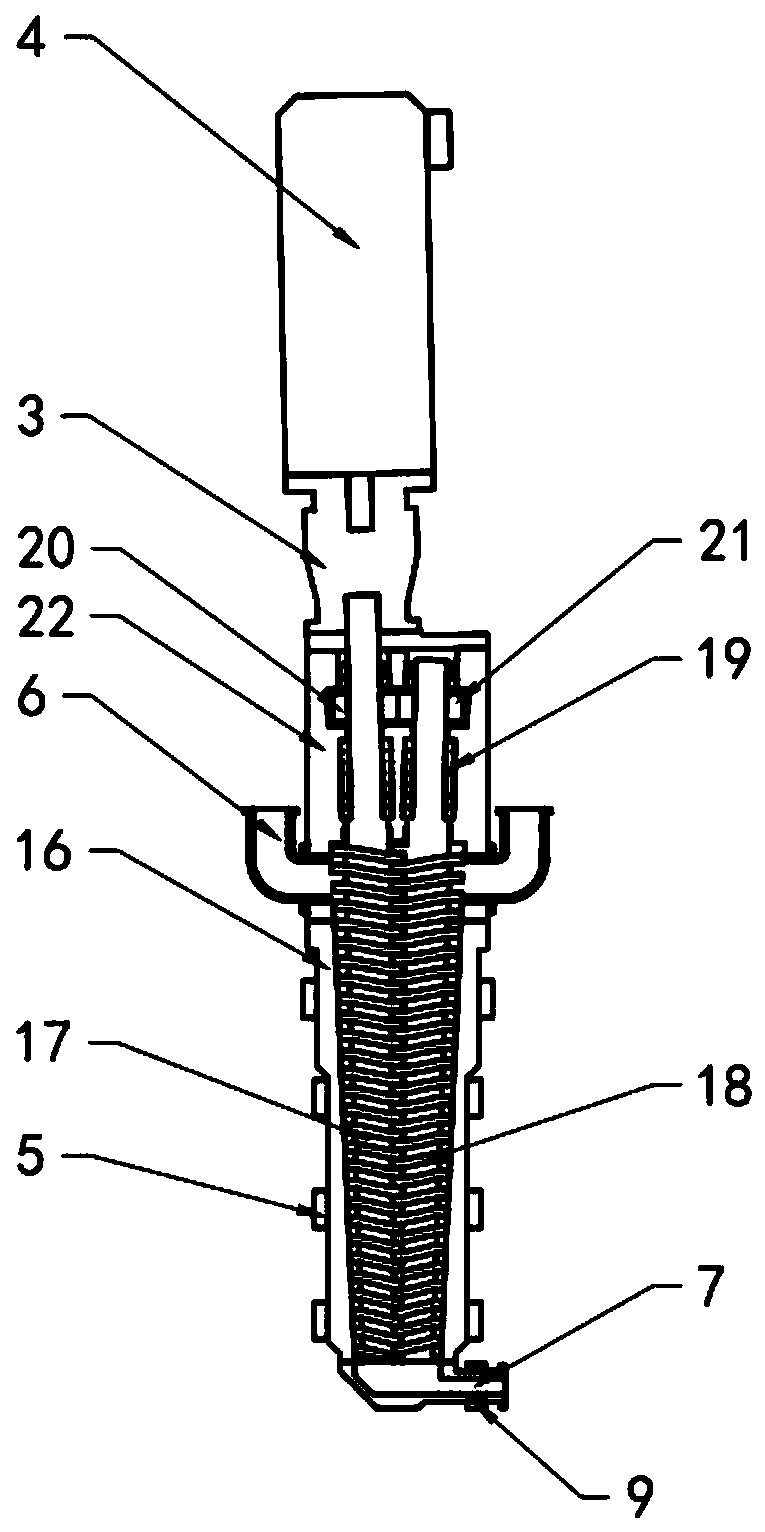

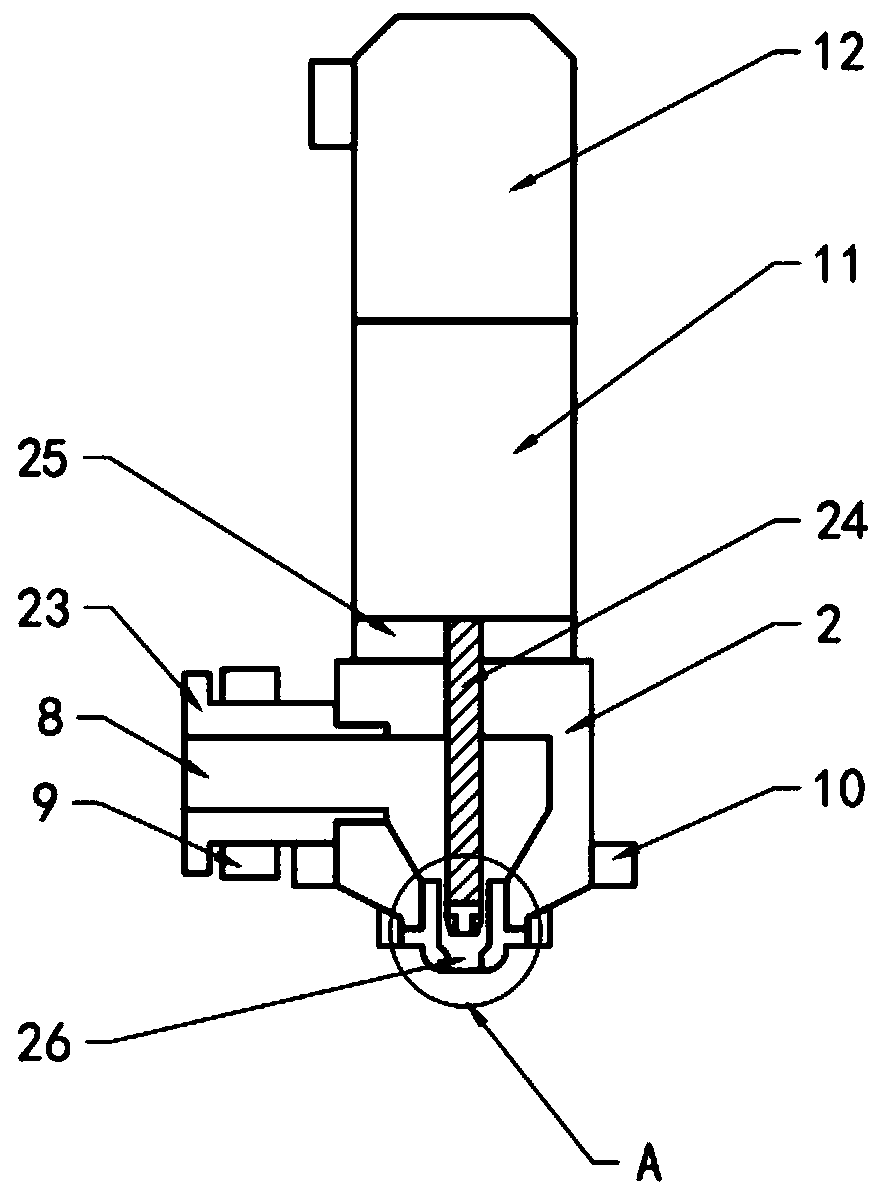

[0017] 3. FDM process (

Fused Deposition Modeling), also known as fused filament deposition, the existing small-scale FDM process mainly uses

thermoplastic wires with a

diameter of about 1mm-3mm as printing materials, and the print head (2) melts the wires to form each The shape of the layer, the technology required by the FDM process is the simplest of all 3D printing process types, except that the moving structure only needs a wire feeding mechanism and a heating head (print head). Compared with the SLS process and the DLP process, the FDM process has no Using expensive materials and not using expensive technology, the forming principle is relatively simple. In theory, as long as the printing line is ten times thicker, the volume increase can be increased by 100 times while the original motion speed remains unchanged. Although The surface accuracy is sacrificed, but in the field of large-scale additive manufacturing, accuracy is not the main problem. On the one hand, large-scale products such as furniture, houses, lamps, decorations, etc. do not require high overall dimensional accuracy. On the other hand, large-scale products require The

surface finish is determined by the

coating process, and the efficiency is the main problem when the size reaches the order of several meters. FDM can greatly improve the

material flow rate,

line width and layer height. The

volumetric efficiency of molding, so there is a possibility of large-scale FDM process

However, the transmission chain of the existing conical counter-rotating twin-screw extruder is very long, and it is difficult to achieve precise transmission.

[0027] On the whole, the existing conical counter-rotating twin-screw extruders have important defects such as large volume and weight, too long drive chain, etc. Of course, they cannot be used alone in 3D printing systems, because hot-melt materials, in addition to extruding In addition to the driving force of the extruder, the pressure generated by

thermal expansion is not controlled by the extruder, and end opening and closing and throttling control are required, which need to be improved according to the characteristics of the 3D printing process

Login to View More

Login to View More  Login to View More

Login to View More