Electric-cylinder-driven modular robot transportation platform

A robot and modular technology, applied in the field of flatbed trucks, can solve the problems of affecting operation efficiency, poor obstacle-surpassing ability of flatbed trucks, low mechanical efficiency, etc., and achieve improved power transmission efficiency and reliability, large movement space and flexibility, and low maintenance The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

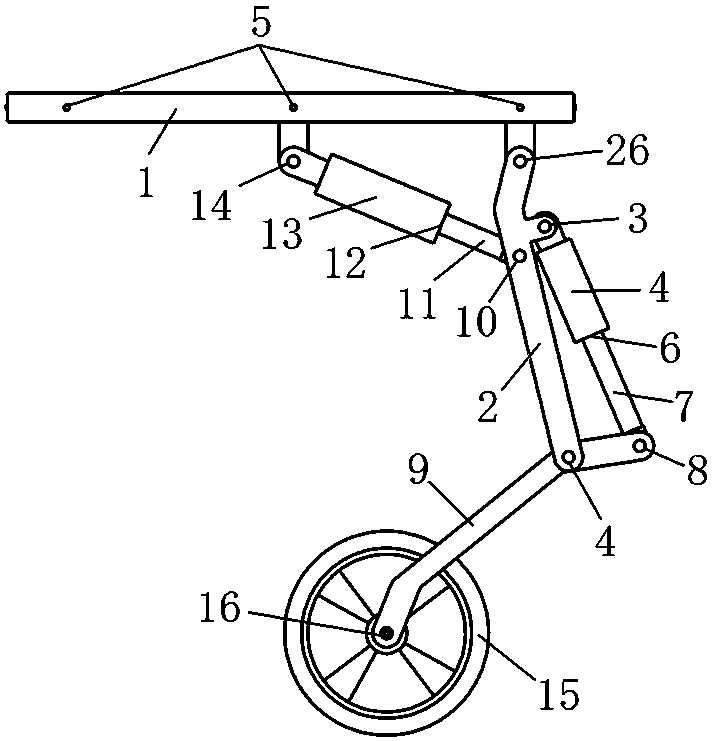

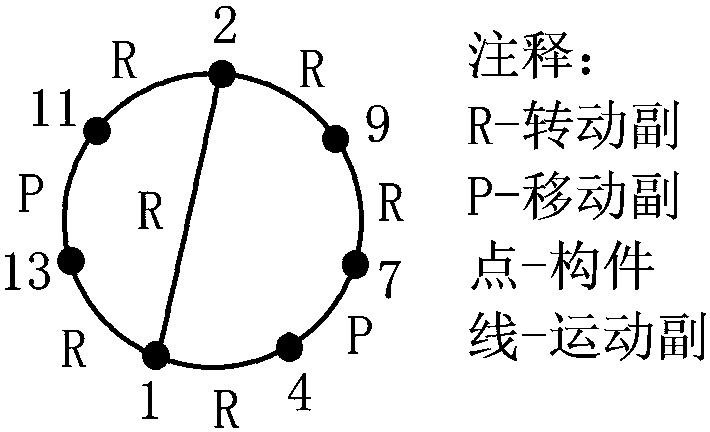

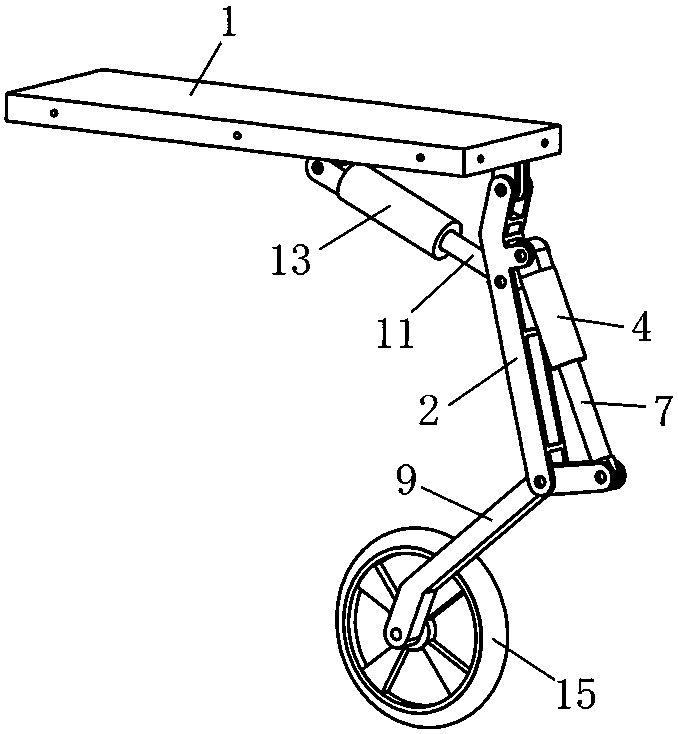

[0024] control figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a modular robot transport platform driven by an electric cylinder, including two or more robot platform units, the robot platform unit includes a robot wheel-leg mechanism and wheels, and the robot wheel-leg mechanism is a seven-rod two-leg mechanism with two moving pairs The degree of freedom link mechanism includes two closed-loop circuits, including a platform 1, a first slide rail 4, a second slide rail 13, a first guide rod 7, a second guide rod 11, a boom 2, and a forearm 9. The two moving pairs are active pairs, driven by servo electric cylinders, the forearm 9 can realize two-degree-of-freedom motion output, and the wheels 15 are installed on the forearm 9. According to real-time road conditions, the two-degree-of-freedom coupling motion of the robot whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com