Method for reinforcing deep and soft soil foundation by combining well-points dewatering with preloading

A technology of well point dewatering and combined surcharge, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of large surcharge, slow loading speed, and high stability requirements, and achieve simple construction procedures and equipment. Suitable for popularization and application, with low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

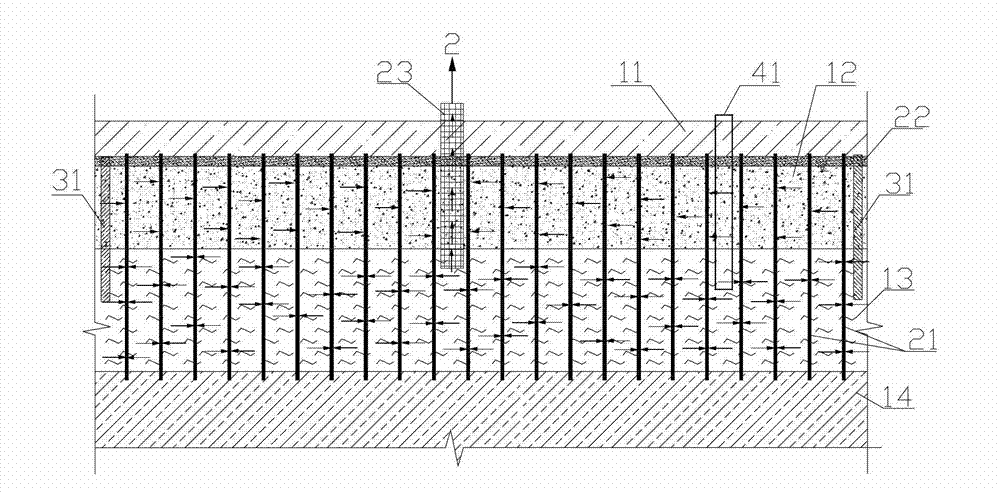

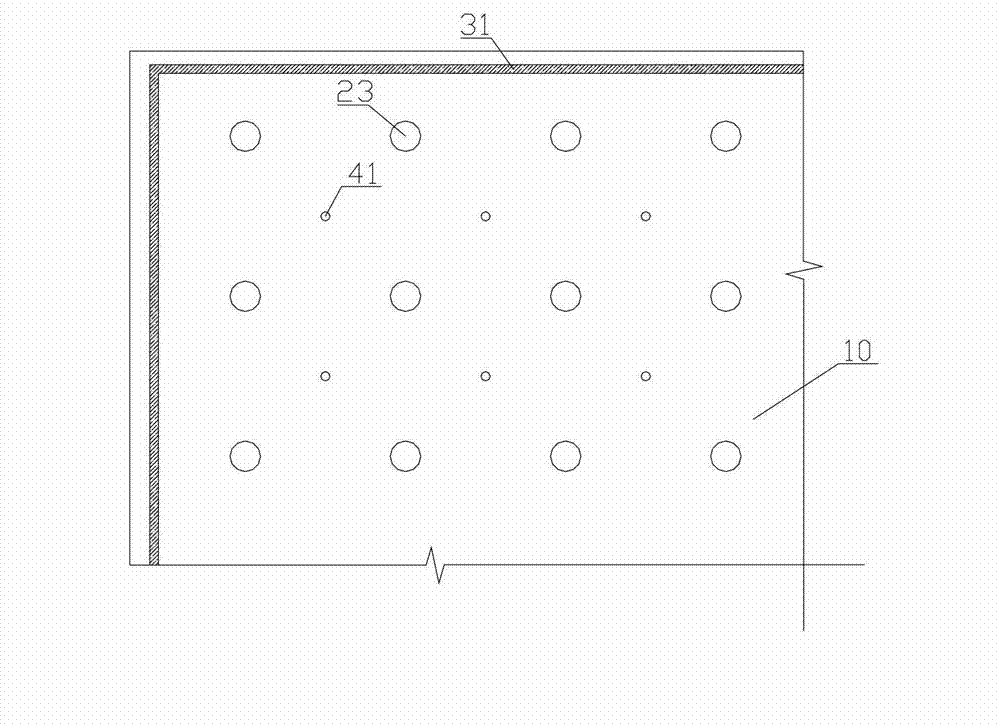

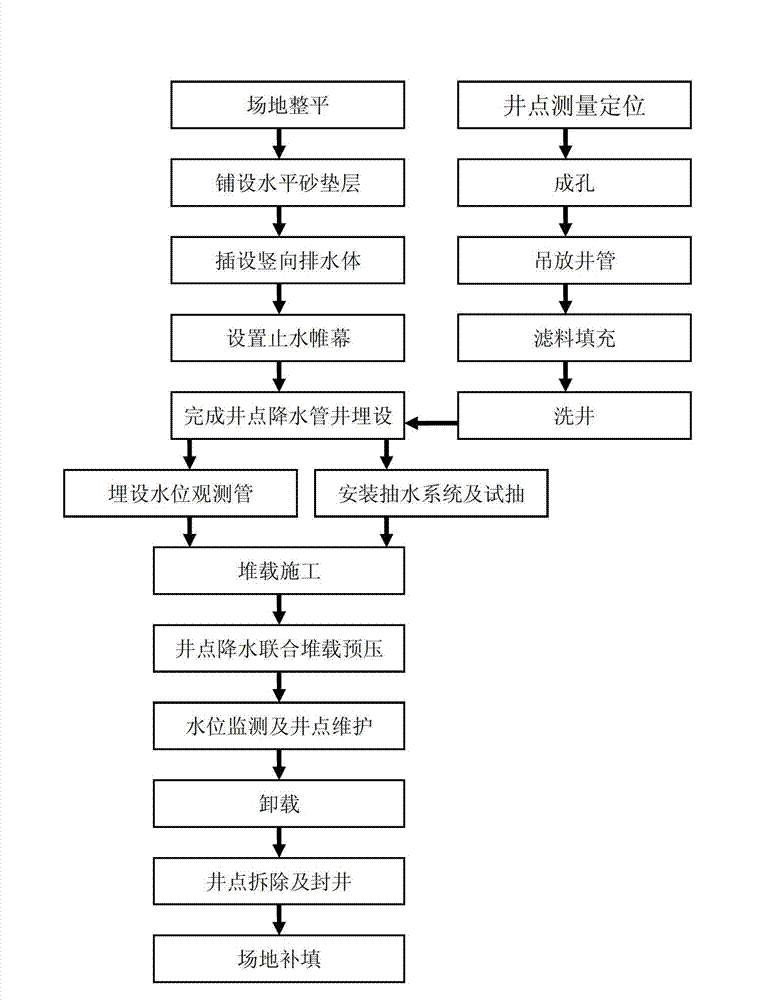

[0032] Such as Figure 1 ~ Figure 3 Shown are the construction process and cross-sectional schematic diagram of the method of well point precipitation combined with preloading preloading to treat soft soil foundation. The present invention is implemented according to the following steps:

[0033] (1) Level the surface of the original site. The soft soil layer below the water surface needs to be filled and then leveled. Filling materials such as sand, rock, and inert demolition materials should be added.

[0034] (2) Lay a 0.5-1.0m thick horizontal drainage sand cushion 22 on the leveled site surface.

[0035] (3) Insert vertical drainage bodies 21, such as plastic drainage boards, bagged sand wells, soft permeable pipes, sand piles or gravel piles, etc. The self-draining sand cushion penetrates the soft soil layer to the design elevation.

[0036] (4) Set up a water-stop curtain 31 at the boundary of the area to be reinforced 10, such as high-pressure jet grouting anti-seepage curtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com