Positioning device for gear mechanism

A positioning device and gear mechanism technology, applied in auxiliary devices, workpiece clamping devices, auxiliary welding equipment, etc., can solve the problems of difficult unloading of workpieces, reduced production efficiency, increased costs, etc., to achieve easy positioning and assembly, and ingenious structure Reasonability, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments shown in the accompanying drawings. However, these embodiments are not limited to the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included within the protection scope of the present invention.

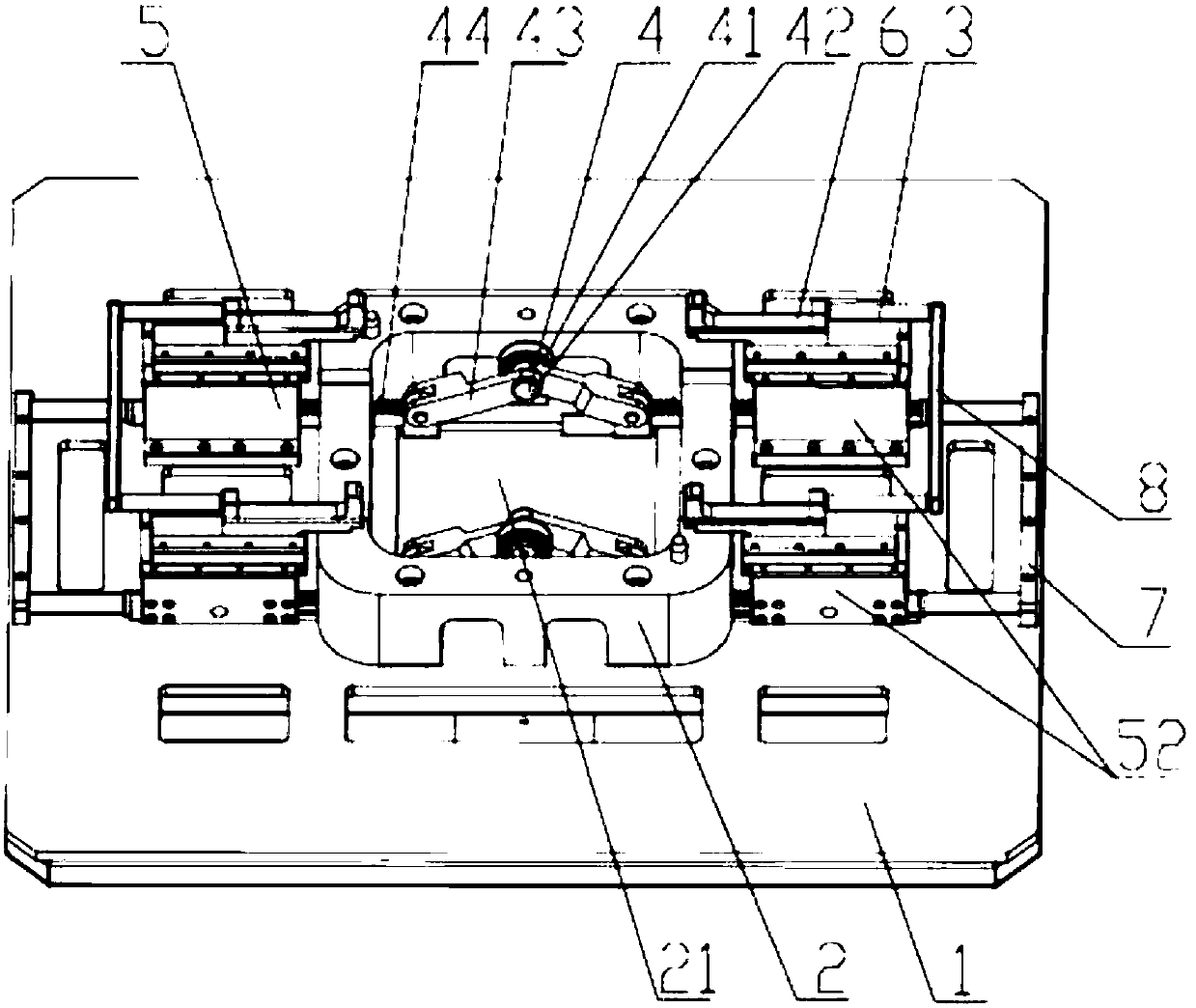

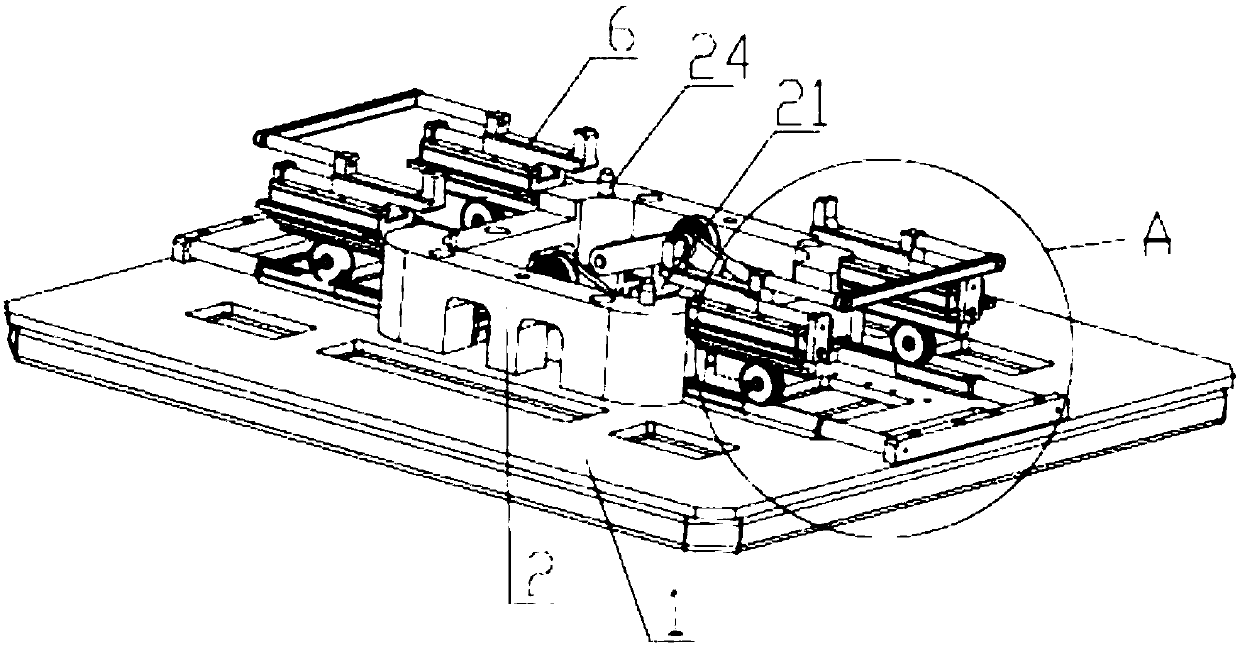

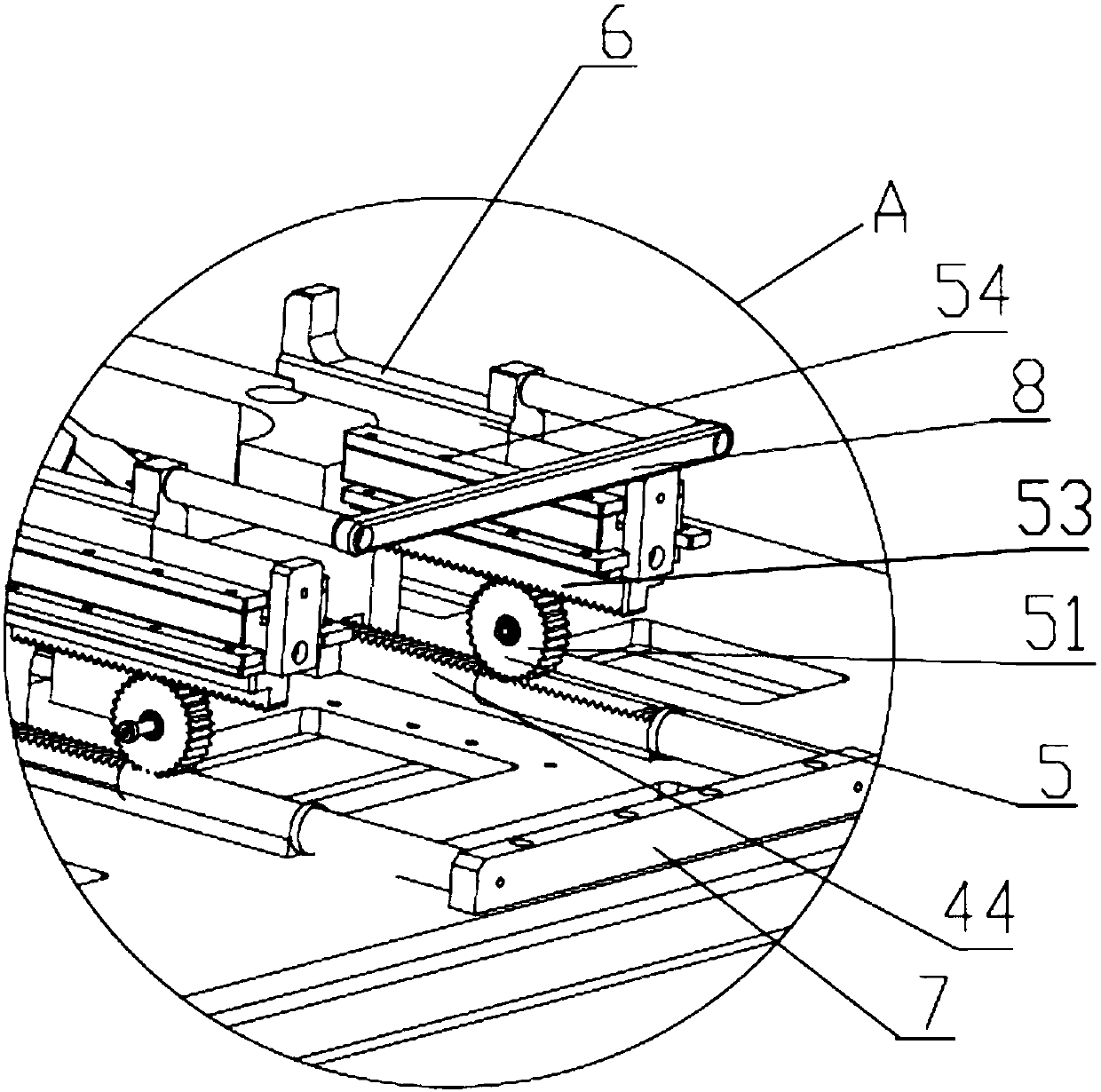

[0020] Such as Figure 1 to Figure 3 As shown, the present invention discloses a gear mechanism positioning device, which includes a base 1 and a limiting block 2 arranged on the base 1, and the limiting block 2 is provided with a receiving space 21 matching the workpiece to be processed ; The position limiting device 2 is also provided with a positioning head 24 that matches the workpiece, and the positioning head 24 can at least partially extend and be placed in the workpiece. The workpiece is over-limited through the accommodating space 21 and the positioning head 24 .

[0021] The base 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com