Lightweight flame-retardant concrete-based inner wall material and preparation method thereof

A wall material and concrete technology, applied in the field of building materials, can solve the problems of low fire resistance and flame retardancy, and achieve the effect of reducing self-weight and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Lightweight flame-retardant concrete-based inner wall material, the wall material is a solid brick body, the solid brick body is composed of an outer layer brick body wrapped with an inner layer brick body, and the inner layer brick body is foamed concrete, The outer layer material is a refractory material,

[0022] The foamed concrete is made of solid components and external components, wherein the solid components are composed of 55% Portland cement and 45% fly ash, and the water-cement ratio is 0.8; the external components It is a vegetable foaming agent and a water reducing agent, and the addition amount of the foaming agent and the water reducing agent is 1% and 1.5% of the solid component respectively;

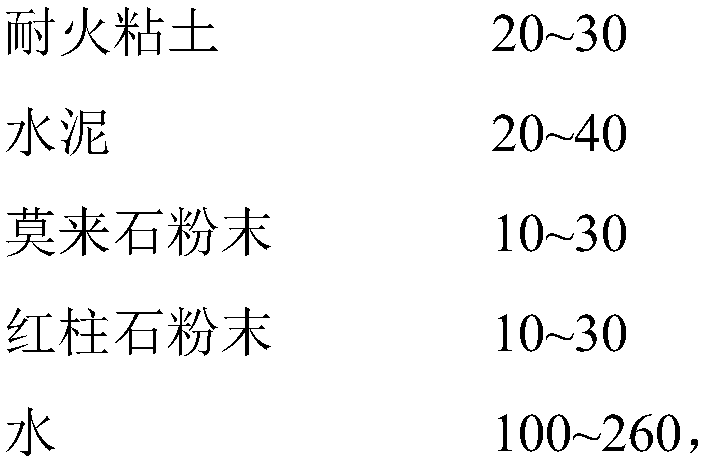

[0023] The refractory material is prepared by the following solid raw materials in parts by weight:

[0024]

[0025] Wherein, the average particle size of the refractory clay and slag powder is 10-20 microns; the average particle size of the mullite powder an...

Embodiment 2

[0028] Lightweight flame-retardant concrete-based inner wall material, the wall material is a solid brick body, the solid brick body is composed of an outer layer brick body wrapped with an inner layer brick body, and the inner layer brick body is foamed concrete, The outer layer material is a refractory material,

[0029] The foamed concrete is made of solid components and external components, wherein the solid components are composed of 44% Portland cement and 56% fly ash, and the water-cement ratio is 0.62; the external components It is a vegetable foaming agent and a water reducing agent, and the addition amount of the foaming agent and the water reducing agent is 2% and 3% of the solid component respectively;

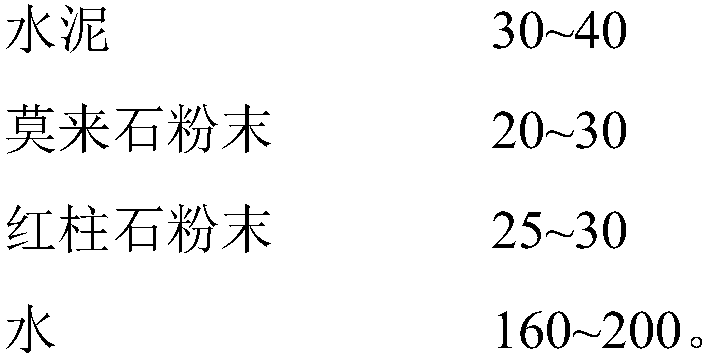

[0030] The refractory material is prepared by the following solid raw materials in parts by weight:

[0031]

[0032] Wherein, the average particle size of the refractory clay and slag powder is 10-20 microns; the average particle size of the mullite powder and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com