Proportional pressure-reducing valve used for beer freshness preservation bucket

A proportional pressure reducing valve and beer fresh-keeping technology, applied in the field of proportional pressure reducing valves, can solve the problems of unfavorable environmental protection, high price, damage to taste and flavor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

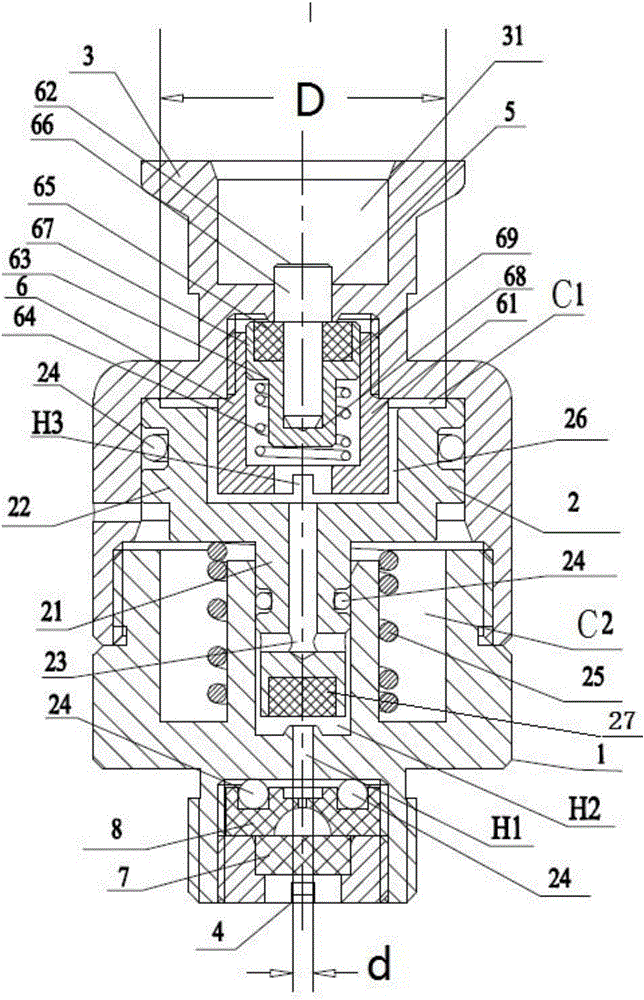

[0033] Such as figure 1 As shown, a proportional pressure reducing valve for beer fresh-keeping barrels, including a pressure reducing valve seat 1, a pressure reducing valve core 2, and a pressure reducing valve valve arranged in sequence along the high pressure end in front of the valve to the low pressure end behind the valve Cover 3, the valve seat 1 of the pressure reducing valve is provided with a medium inflow port 4, the valve cover 3 of the pressure reducing valve is provided with a medium outflow port 5, and the medium outflow port 5 is provided with a check valve body 61 The one-way valve 6.

[0034] When the one-way valve 6 is opened, the gas entering from the high-pressure end before the valve can pass through the one-way valve and exit from the low-pressure end after the valve.

[0035]The bottom of the one-way valve body 61 is provided with a one-way valve body longitudinal hole H3 communicating with the medium inlet 4; The one-way valve spool 63 of the force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com