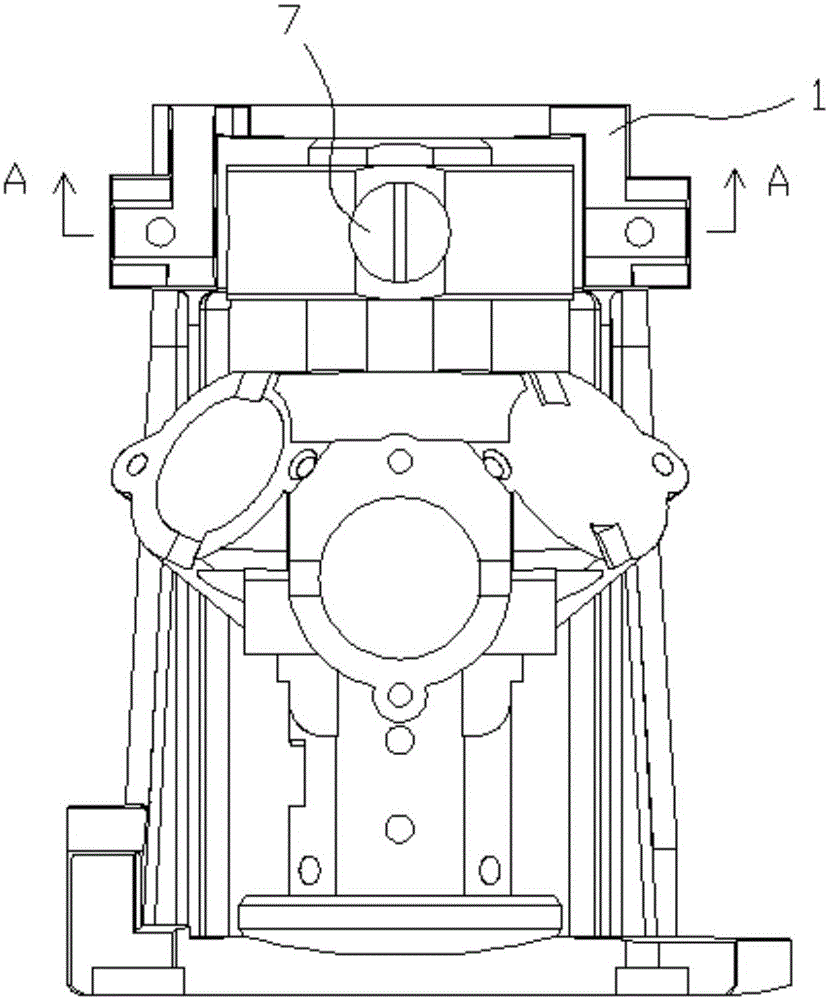

Automatic leveling structure

An automatic leveling and self-adjusting technology, applied in the field of line casting instruments, can solve problems such as inconvenience, uneven placement, and inclination, and achieve the effects of extending service life, improving impact resistance and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

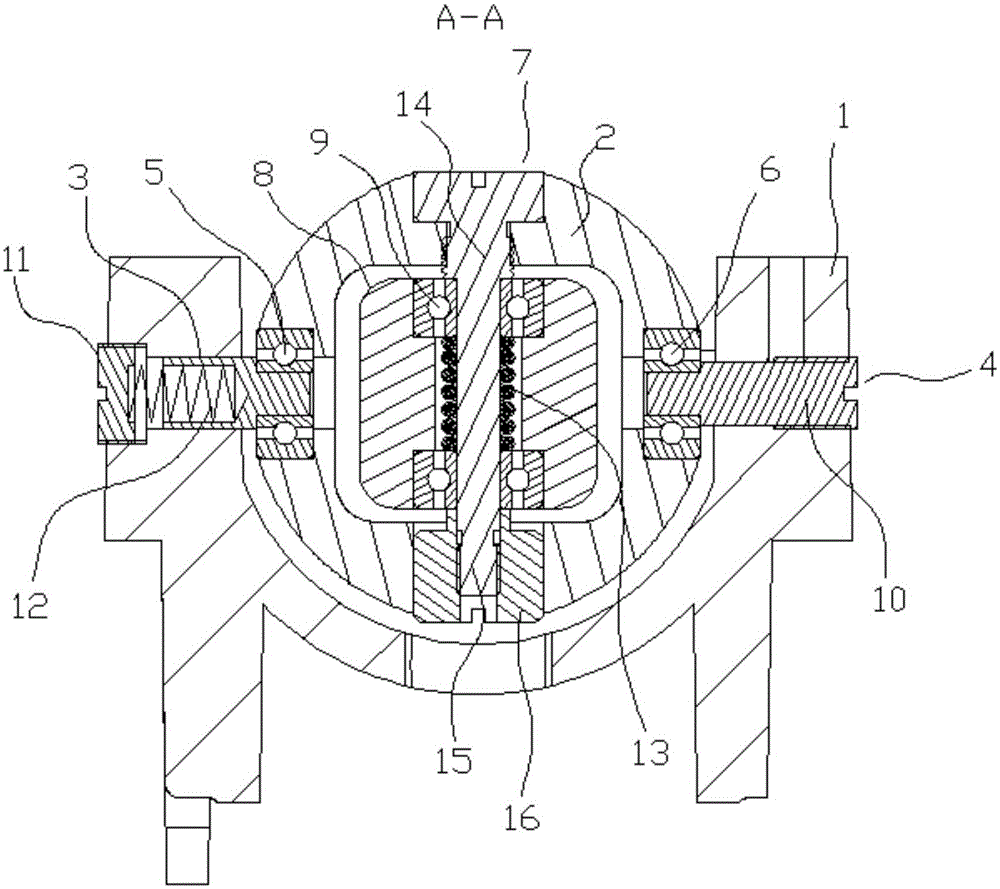

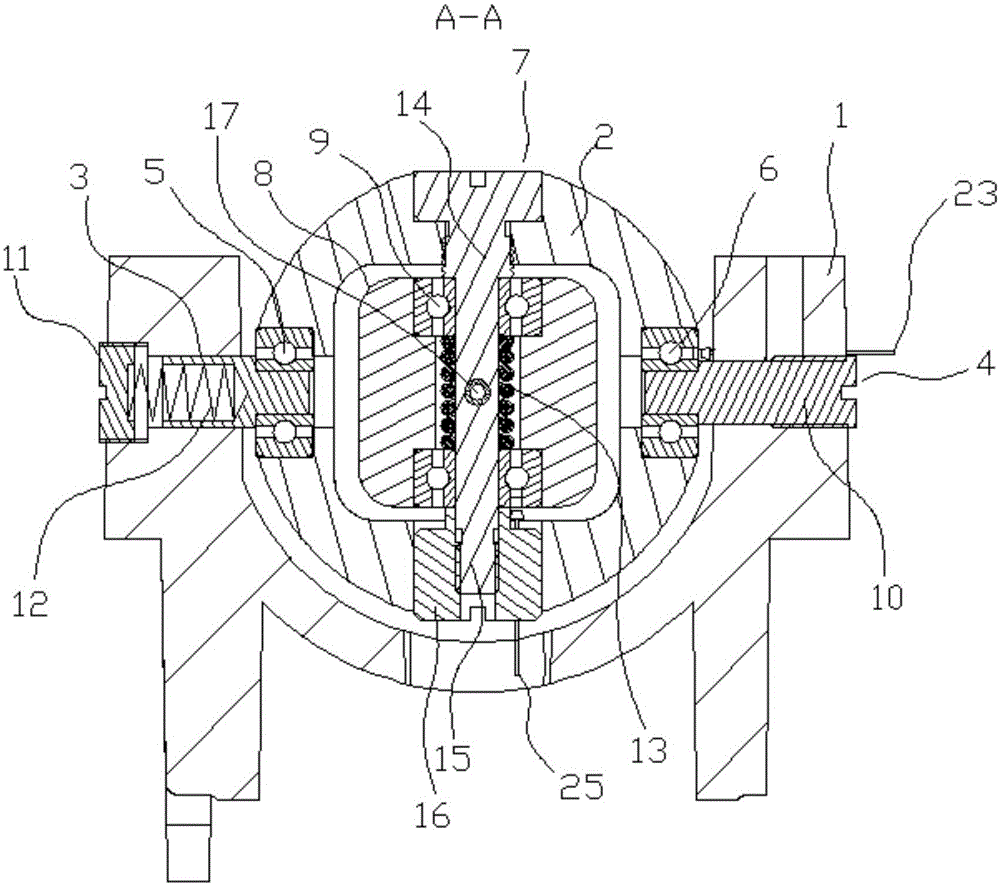

[0024] Embodiment 2: the structure and specific implementation of this embodiment are the same as embodiment 1, and its difference is, as Figure 3 to Figure 6As shown in: the inner compensation shaft is provided with a tube hole, and the tube hole is provided with a sliding positioning tube 17 that is slidingly fitted with the tube hole, and the axis of the sliding positioning tube is perpendicular to the axis of the inner compensation shaft , the sliding positioning tube is slidingly connected with the inner compensation shaft, the inner compensation seat is provided with a positioning hole, the diameter of the positioning hole is adapted to the outer diameter of the sliding positioning tube, and the positioning hole and the sliding positioning tube Coaxial, the inner compensating seat is provided with a lower storage tank 18, the lower storage tank is located below the positioning hole and communicates with the positioning hole, the positioning hole is provided with a top bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com