Automatic creation method based on specialized service work order of equipment

A technology for automatically creating and working orders, applied in the direction of instruments, etc., can solve problems such as work order dispatch errors, hidden dangers of equipment failures, and wrong judgment of equipment daily maintenance failure information, so as to deal with equipment abnormalities in time and ensure the safe operation of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

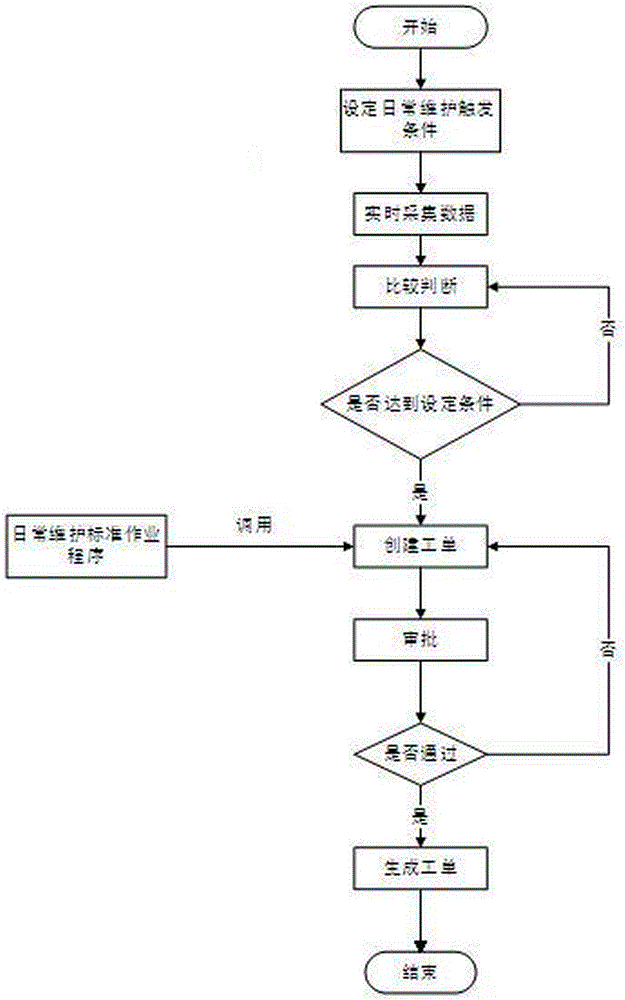

[0046] An automatic creation method based on equipment specialized service work orders, including the creation of daily maintenance work orders, the creation of the daily maintenance work orders includes the following steps:

[0047] a. Set the trigger conditions for the daily maintenance items of the equipment;

[0048] b. Real-time collection of operating parameters of the equipment;

[0049] c. Compare and judge whether the collected operation parameter value meets the set trigger condition;

[0050] d. If the set trigger condition is not met, proceed to step c;

[0051] e. If the set trigger conditions are met, a daily maintenance work order will be automatically created and the corresponding daily maintenance standard operating procedure will be invoked;

[0052] f. Generate daily maintenance work orders.

[0053] In this embodiment, the trigger condition for setting the daily maintenance items of the equipment in the step a refers to: setting the trigger values of t...

Embodiment 2

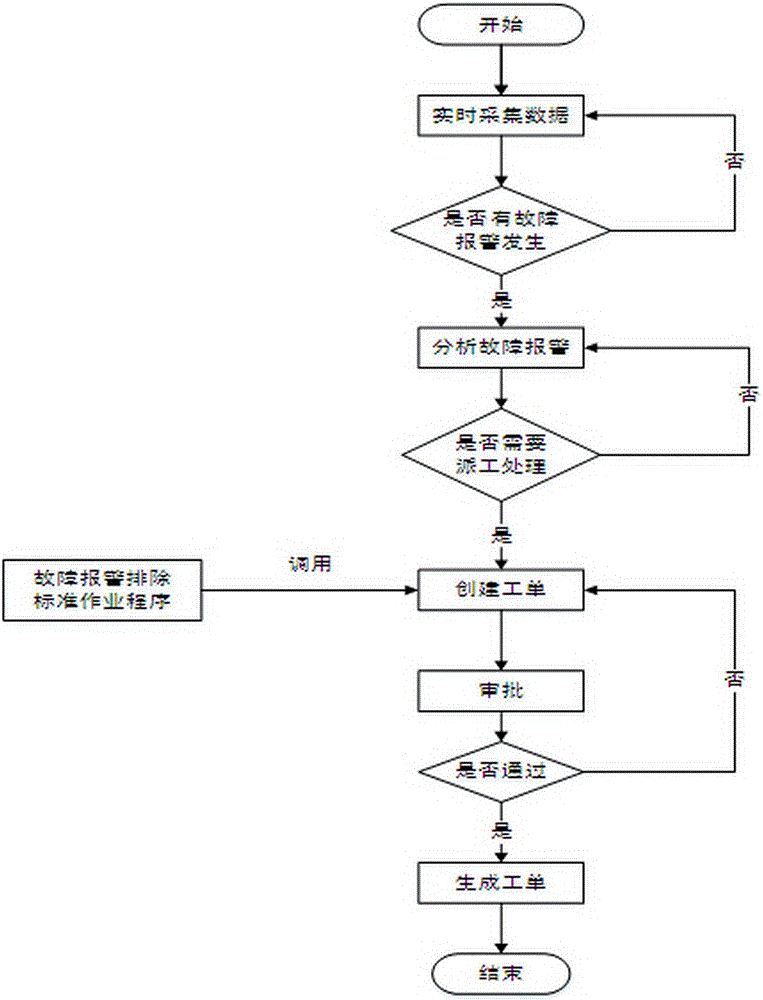

[0061] An automatic creation method based on equipment specialized service work orders, including the creation of daily maintenance work orders and the creation of fault alarm removal work orders,

[0062] The creation of the daily maintenance work order includes the following steps:

[0063] a. Set the trigger conditions for the daily maintenance items of the equipment;

[0064] b. Real-time collection of operating parameters of the equipment;

[0065] c. Compare and judge whether the collected operation parameter value meets the set trigger condition;

[0066] d. If the set trigger condition is not met, proceed to step c;

[0067] e. If the set trigger conditions are met, a daily maintenance work order will be automatically created and the corresponding daily maintenance standard operating procedure will be invoked;

[0068] f. Generate daily maintenance work orders.

[0069] The creation of the troubleshooting work order for the fault alarm includes the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com