Electric power supply equipment provided with roller grooves

A technology of electric power supply and roller groove, which is applied to the parts, circuits, and electrical components of the connection device, and can solve the problems of difficult reliability of clamping force, difficulty in inserting clamping force, and affecting power supply stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

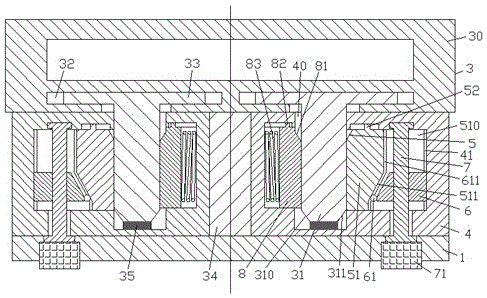

[0009] Combine below figure 1 The present invention will be described in detail.

[0010] An electric power supply device provided with a roller groove according to an embodiment includes a pin-type insertion device 3 and a socket-type fixing device. The pin-type insertion device 3 includes a body portion 30 and a center of the body portion 30. Two pin-type plugs 31 are arranged axially symmetrically. The upper part of the two pin-type plugs 31 is provided with a guiding horizontal portion 33 for slidably interacting with the two sliding grooves 32 provided in the body portion 30 The corresponding one of the slidably fits and bears the force and load in the up and down direction. The socket-type fixing device includes a base 1 and two mounting brackets 4 fixed on the base 1 and symmetrically arranged about the central axis, each Each of the mounting brackets 4 is provided with a slot 40 for inserting a corresponding one of the two pin plugs 31, and each of the mounting brackets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com