Capacitive fill level sensor

A filling level, capacitive technology, applied in the direction of instruments, liquid level indicators, liquid level indicators for physical variable measurement, etc., to achieve the effect of cheap manufacturing and delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

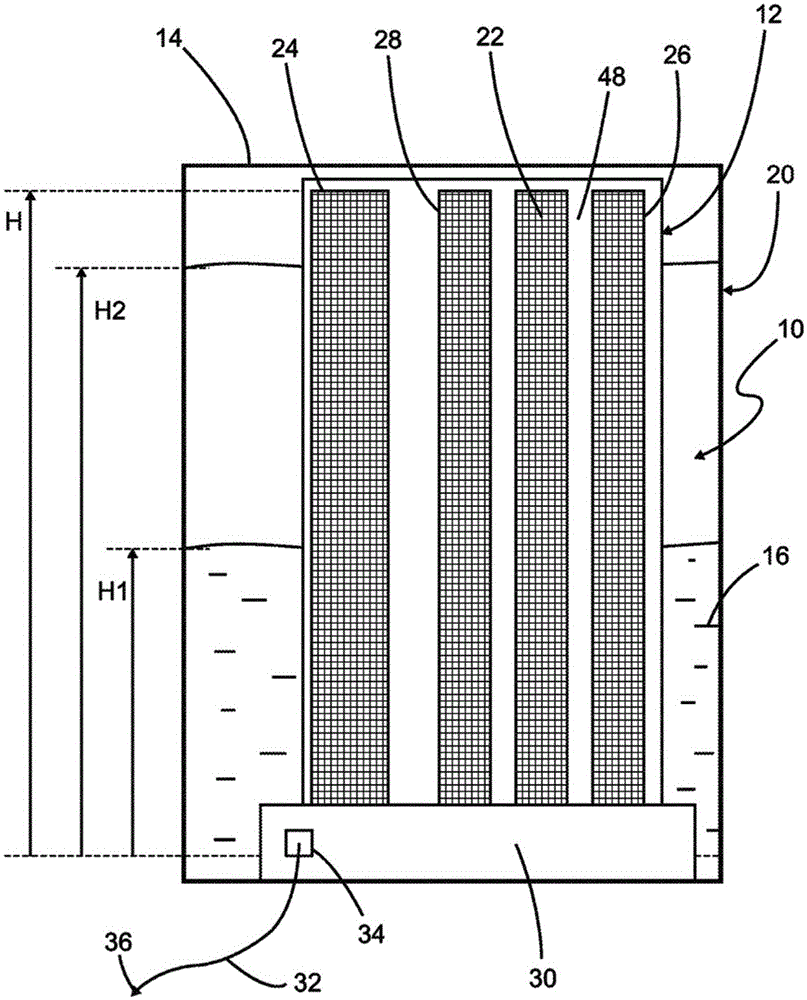

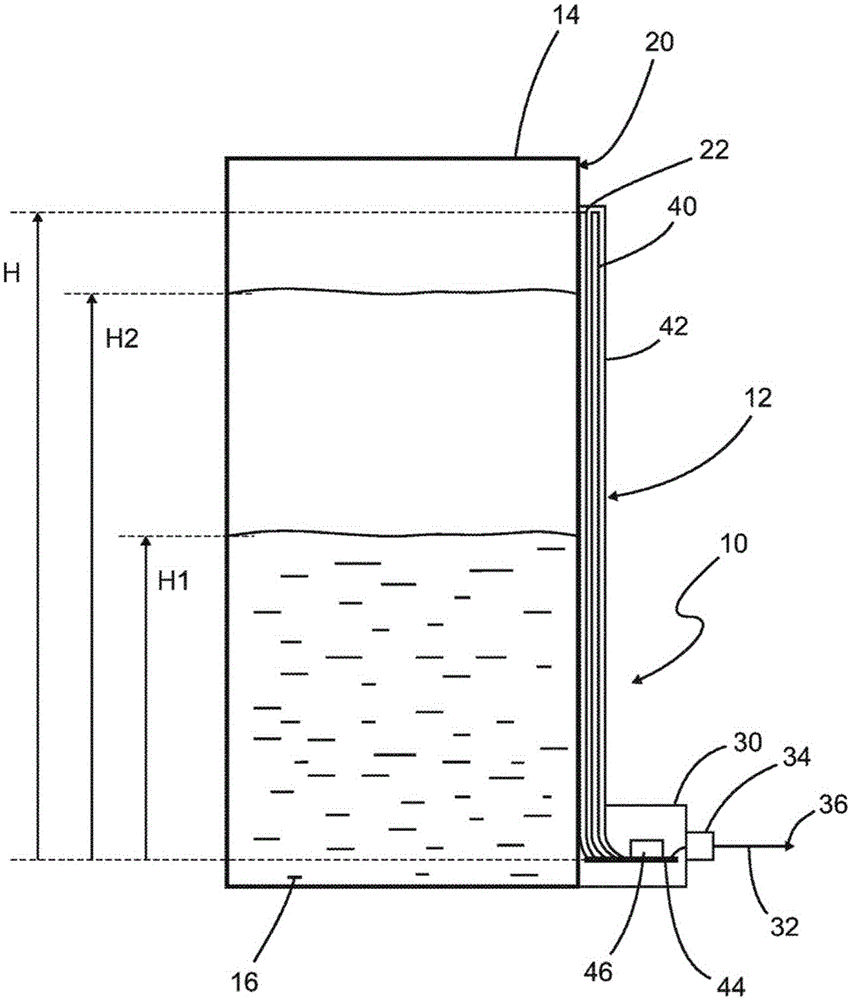

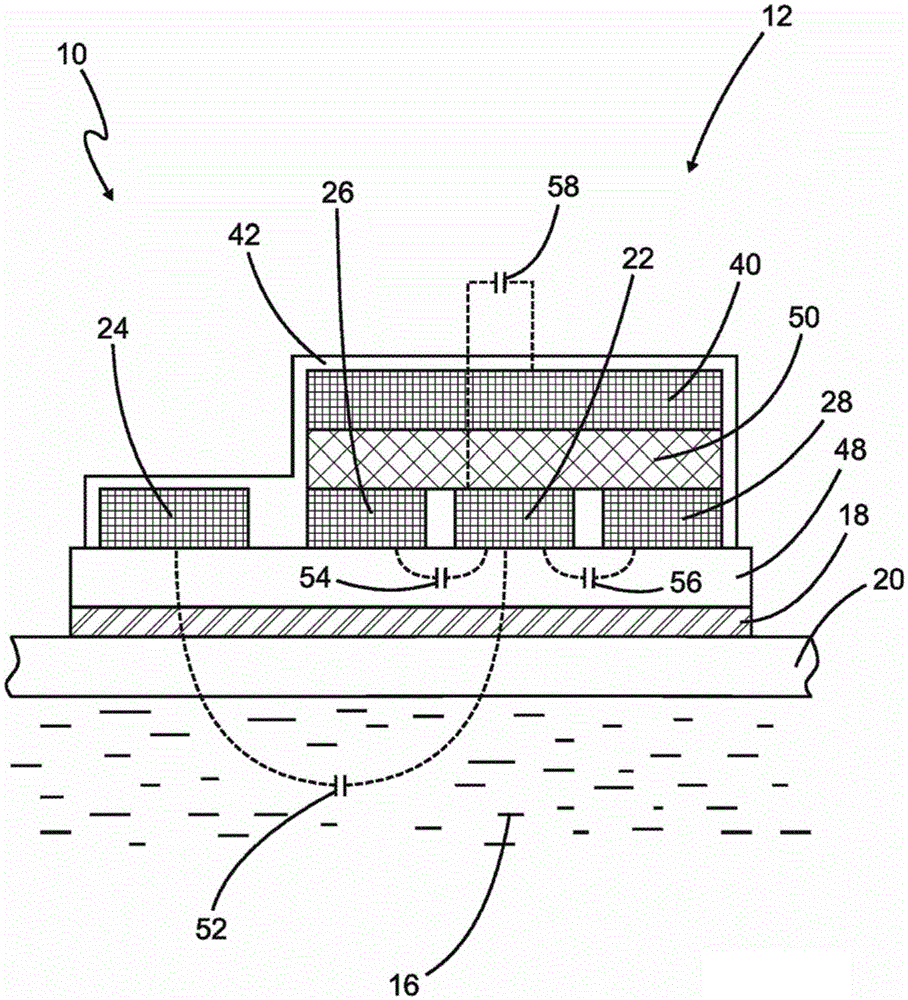

[0049] figure 1 A capacitive fill-level sensor 10 according to the invention is shown, which is cut in the vertical direction in the region of the electrode unit 12 . The capacitive fill level sensor 10 measures the fill level H1 , H2 of a medium 16 which is located in the container 14 within the fill level measuring range H. FIG. In the exemplary embodiment shown, the medium 16 has a first fill level H1. A possible second fill level H2 is also shown.

[0050] The electrode unit 12 is adhered to the outer wall 20 of the container 14 by means of an adhesive layer 18 . Due to the partially cut out depiction, the measuring electrode 22 , the counter electrode 24 , the first shielding electrode 26 and the second shielding electrode 28 are visible. The electrode unit 12 is connected to a first electronics unit 30 which is arranged at the lower end of the container 14 in the exemplary embodiment shown. An output signal 36 is provided via the line 32 which is in contact with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com