Bamboo-wood composite carriage baffle for truck as well as manufacturing method of same

A truck, bamboo and wood composite technology, applied in the direction of manufacturing tools, plywood presses, wood veneer bonding, etc., can solve problems such as poor quality of plywood, and achieve improved use value, good appearance, and smooth appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further explained below in conjunction with the drawings and embodiments:

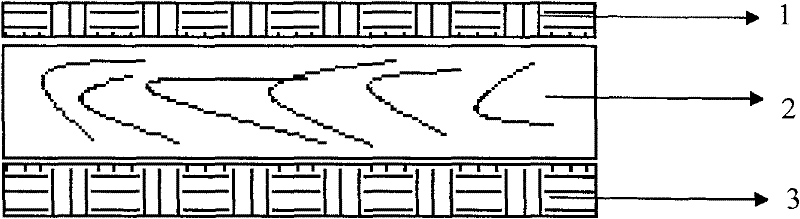

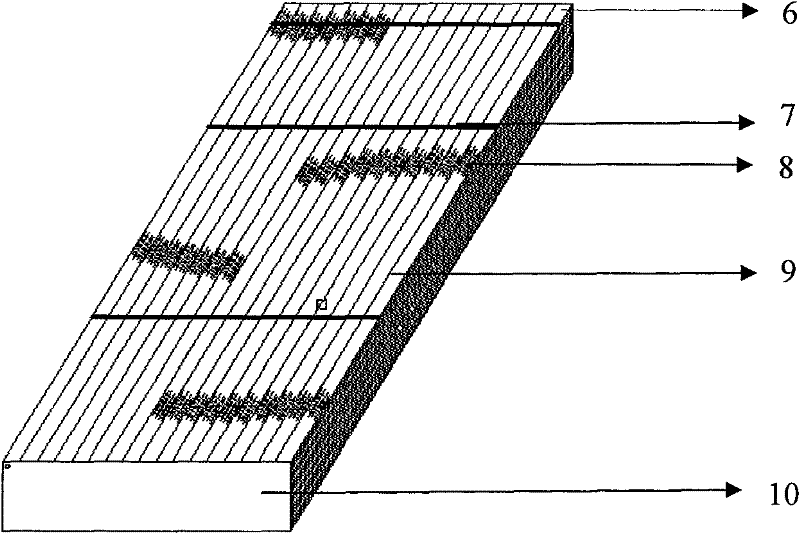

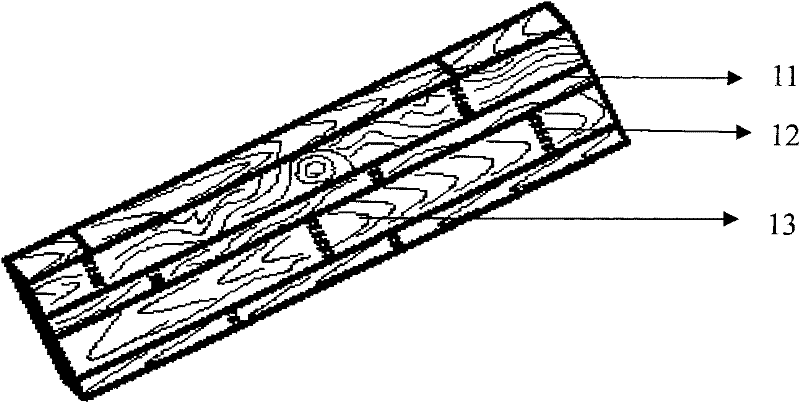

[0017] Such as figure 1 As shown, a bamboo-wood composite truck compartment railing includes surface layers 1, 3 and a core layer 2. The surface layers 1 and 3 are high-strength laminates with a thickness of 2-10mm full longitudinal thin bamboo curtains. Layer 2 is a 10-30mm thick cedar finger joint board, and the surface layer and the core layer are glued together by phenolic resin glue.

[0018] The sides of the bamboo-wood composite truck compartment fence can be chamfered, tongue-and-groove, and tongue-and-groove. After processing, the fence board is painted with weather-resistant paint, and the groove or tongue and groove are used to join in the width direction during installation. In addition, during the production and processing of the board, fire-proof, anti-mildew, and anti-corrosion treatments are carried out to ensure its adaptability in all aspects.

[0019] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com