Double-walled housing for industrial panels and panel-PCs

A technology of operation screen and computer, applied in computing, instrument, electrical digital data processing and other directions, can solve the problems of frame manufacturing trouble and high cost, and achieve the effect of improving stability and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

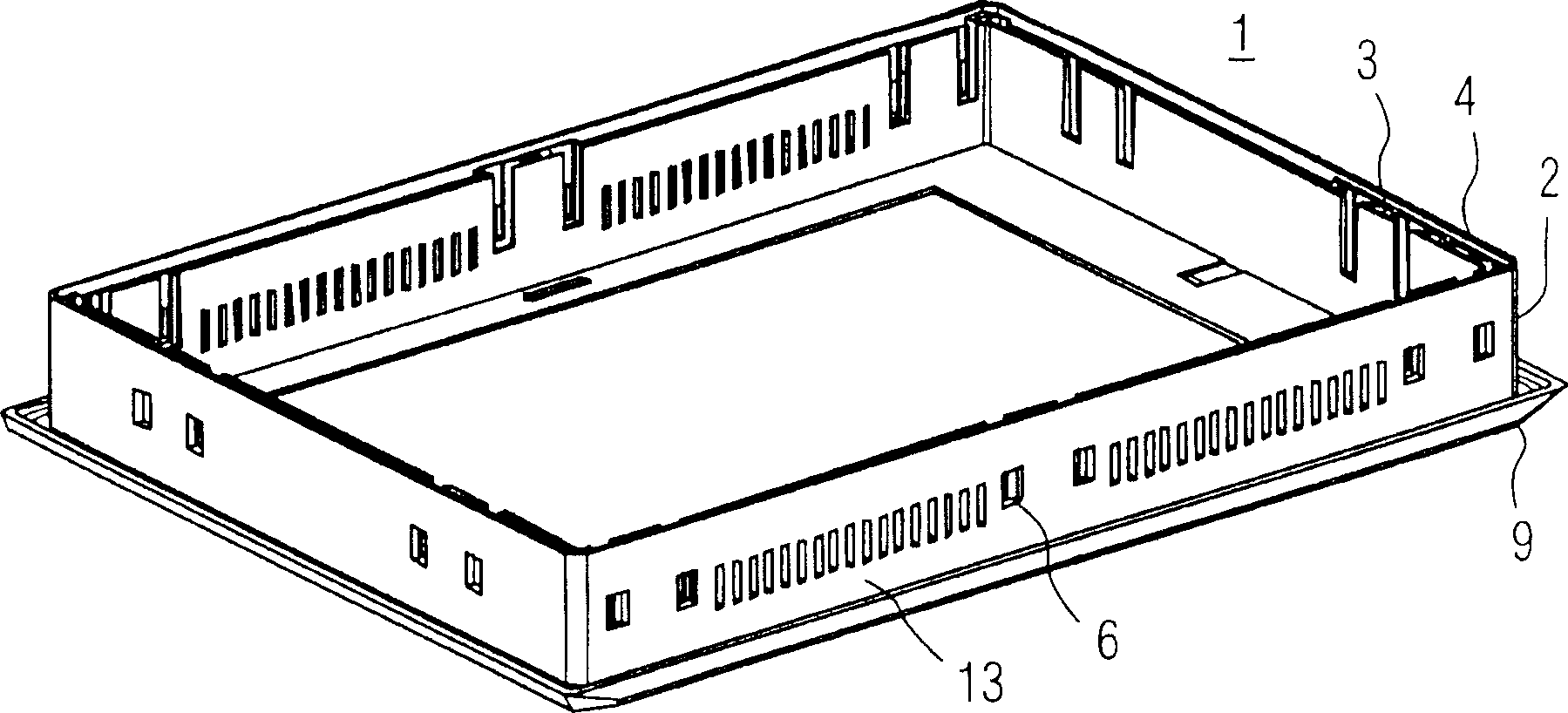

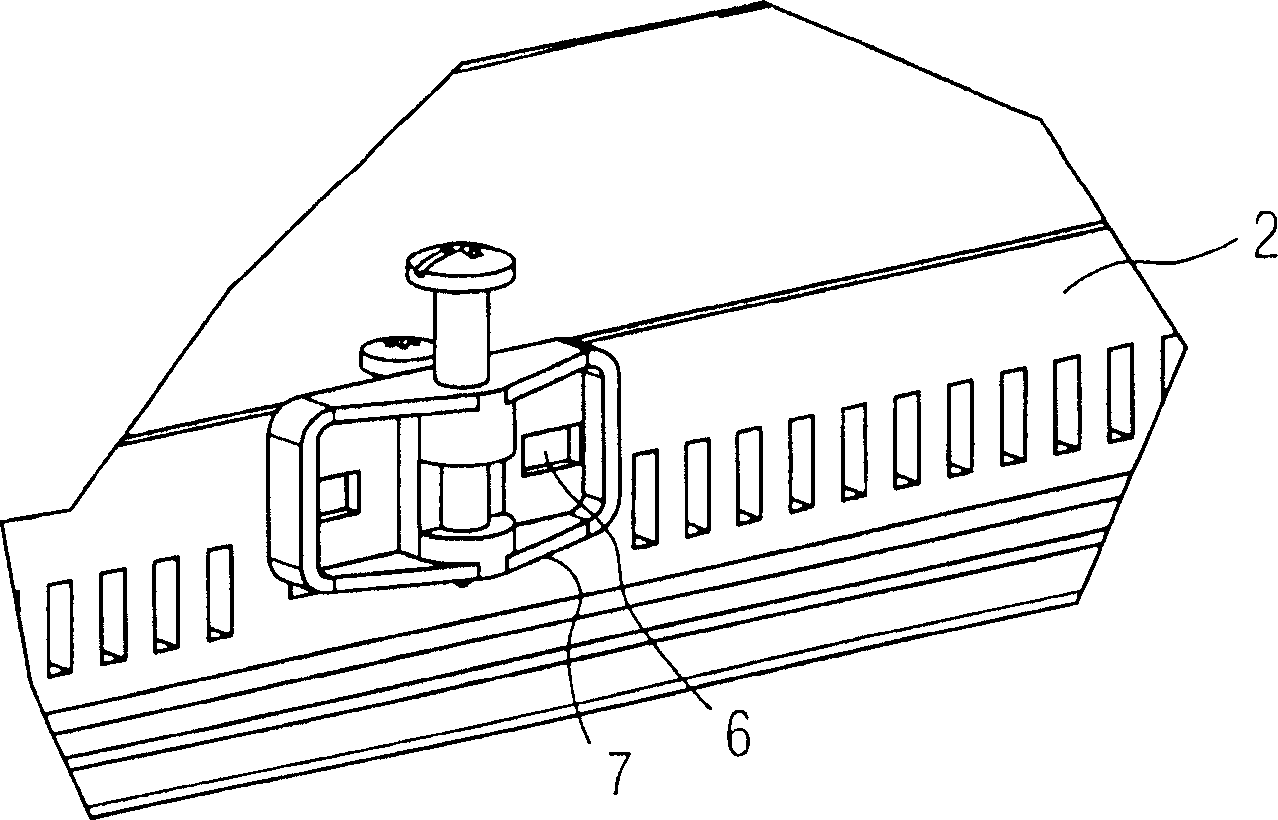

[0026] figure 1 A housing 1 with a double-walled frame 2 consisting of an inner wall 3 and an outer wall 4 is shown. The inner and outer walls are arranged substantially parallel to each other. The housing has a perforated plate 9 on the front side. The frame 2 has ventilation seams 13 in places. At the same time, the frame 2 has connection points 6 for clamping means 7 for fastening in a wall.

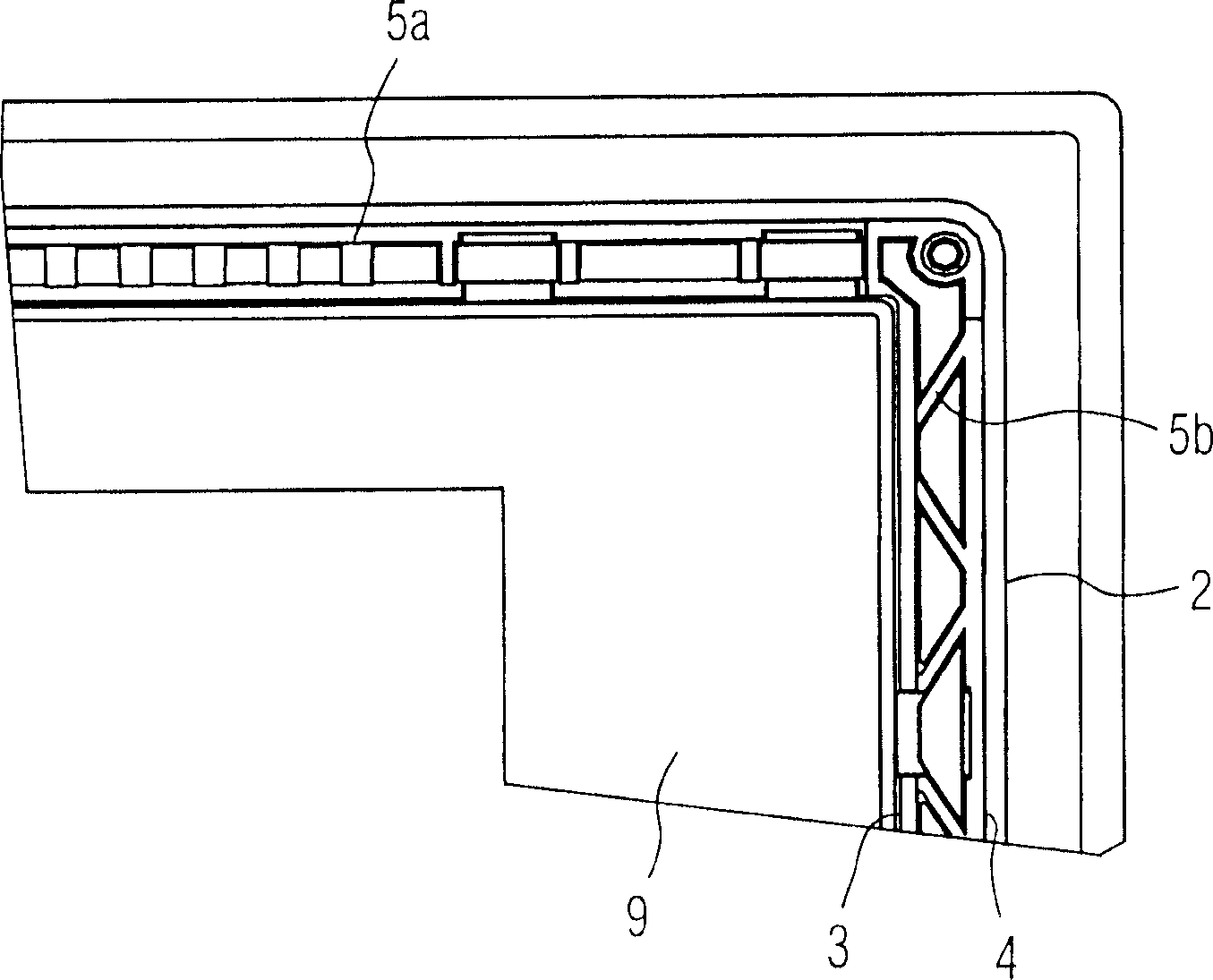

[0027] figure 2 A partial view of the double-walled frame 2 is shown, wherein the inner wall 3 and the outer wall 4 are connected to each other by cross braces or ribs 5a, 5b. The frame 2 here consists essentially of plastic and has a perforated plate 9 on the front side. In this case, the cross brace or connection between the inner wall 3 and the outer wall 4 can extend at right angles to the frame wall 5 a or substantially at an angle of 45° to the frame wall 5 b. Through the ribs or connections between the two layers of frame walls 3, 4, the double-walled frame 2 achieves hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com