Machine for producing ice

A technology of machines and refrigerating units, applied in the direction of ice making, ice making, applications, etc., which can solve problems such as inaccessibility to components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the above figures, the machine for making ice is indicated by the reference number 1 .

[0023] The machine 1 is used in particular for making "ice cubes", in other words, for making small ice cubes of cylindrical shape with a desired diameter.

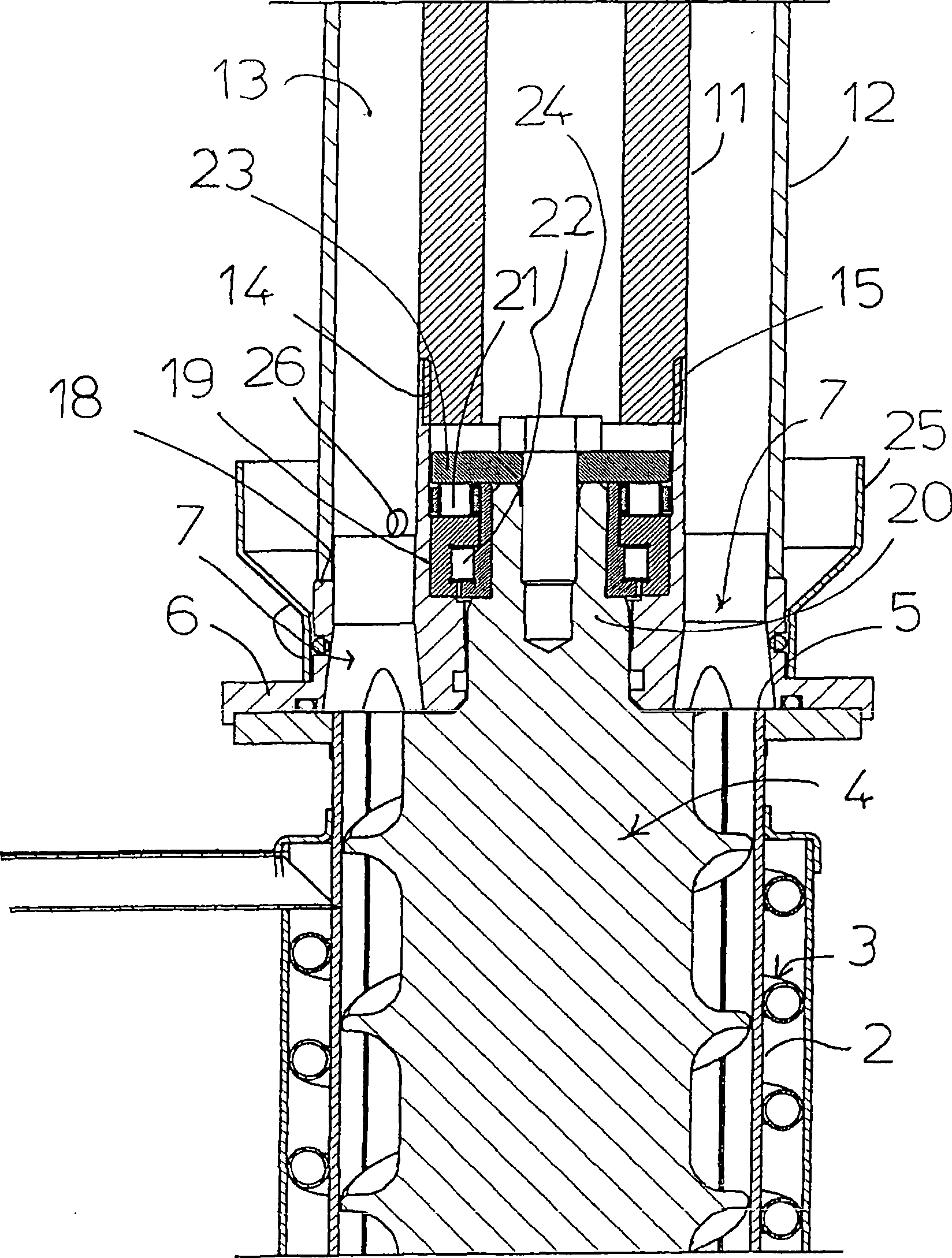

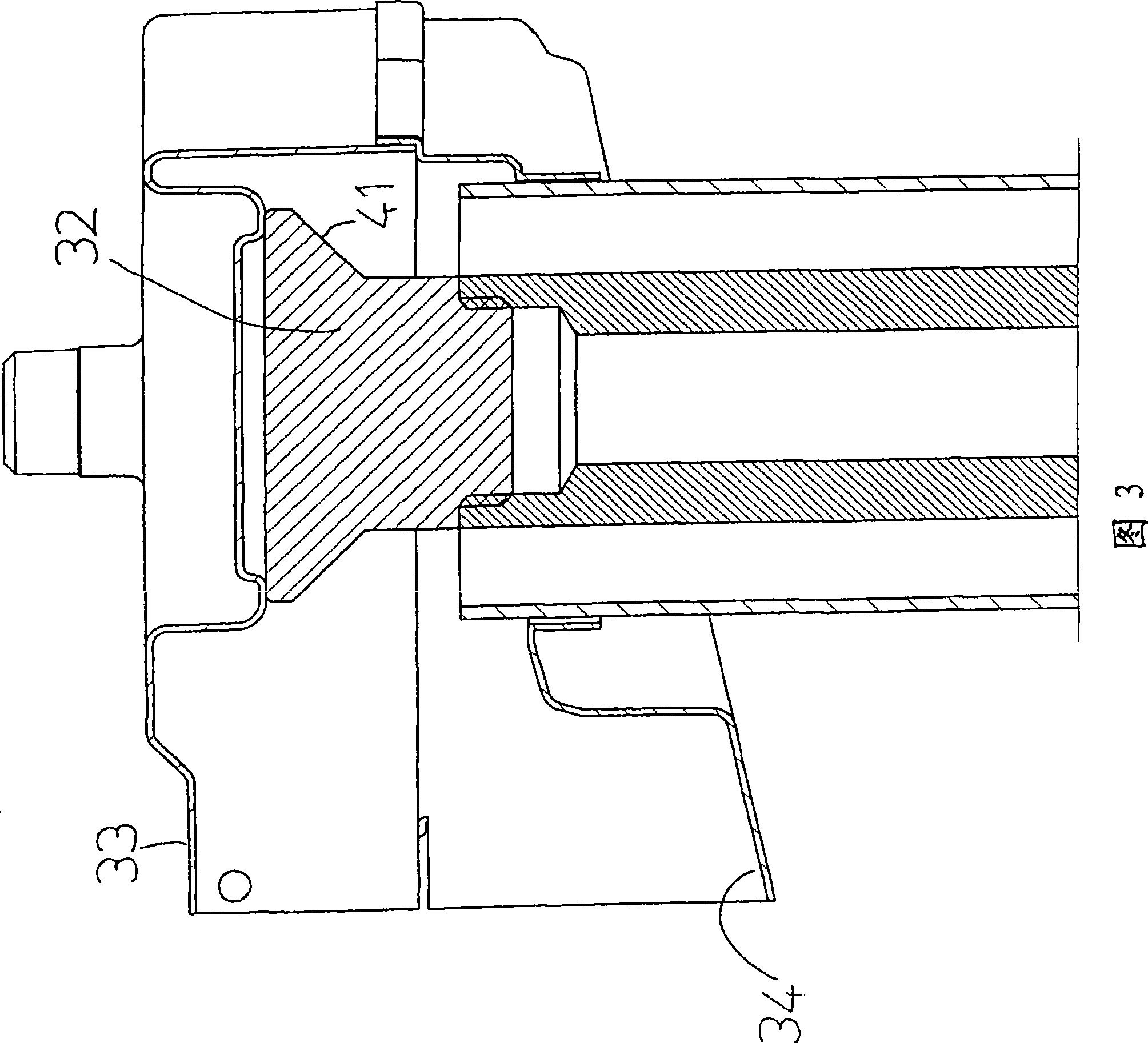

[0024] The machine 1 comprises a tubular duct 2 for forming ice, said tubular duct 2 being surrounded by an evaporator 3 of a refrigeration unit (not shown), said machine 1 also comprising an auger 4 for conveying ice to an outlet 5 , the output port 5 is combined with a ring nut 6, and the ring nut 6 is provided with a plurality of extraction holes 7 spaced at specific angles along the circumferential direction.

[0025] The ring nut 6 comprises a central sleeve 19 in which the top shaft center 20 of the shaft of the screw conveyor 4 is positioned and supported in a fixed position by means of rotary bearings 21 and 22 located in the ring Between the inner side surface of the central sleeve 19 of the nut 6 and the side surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com