crt display device dismantling equipment

A display device and equipment technology, which is applied in the direction of solid waste removal, electronic waste recycling, recycling technology, etc., can solve the problems of no CRT display device disassembly equipment, low production efficiency, low degree of automation, etc., and achieve resource utilization. The effect of maximizing, improving efficiency, improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

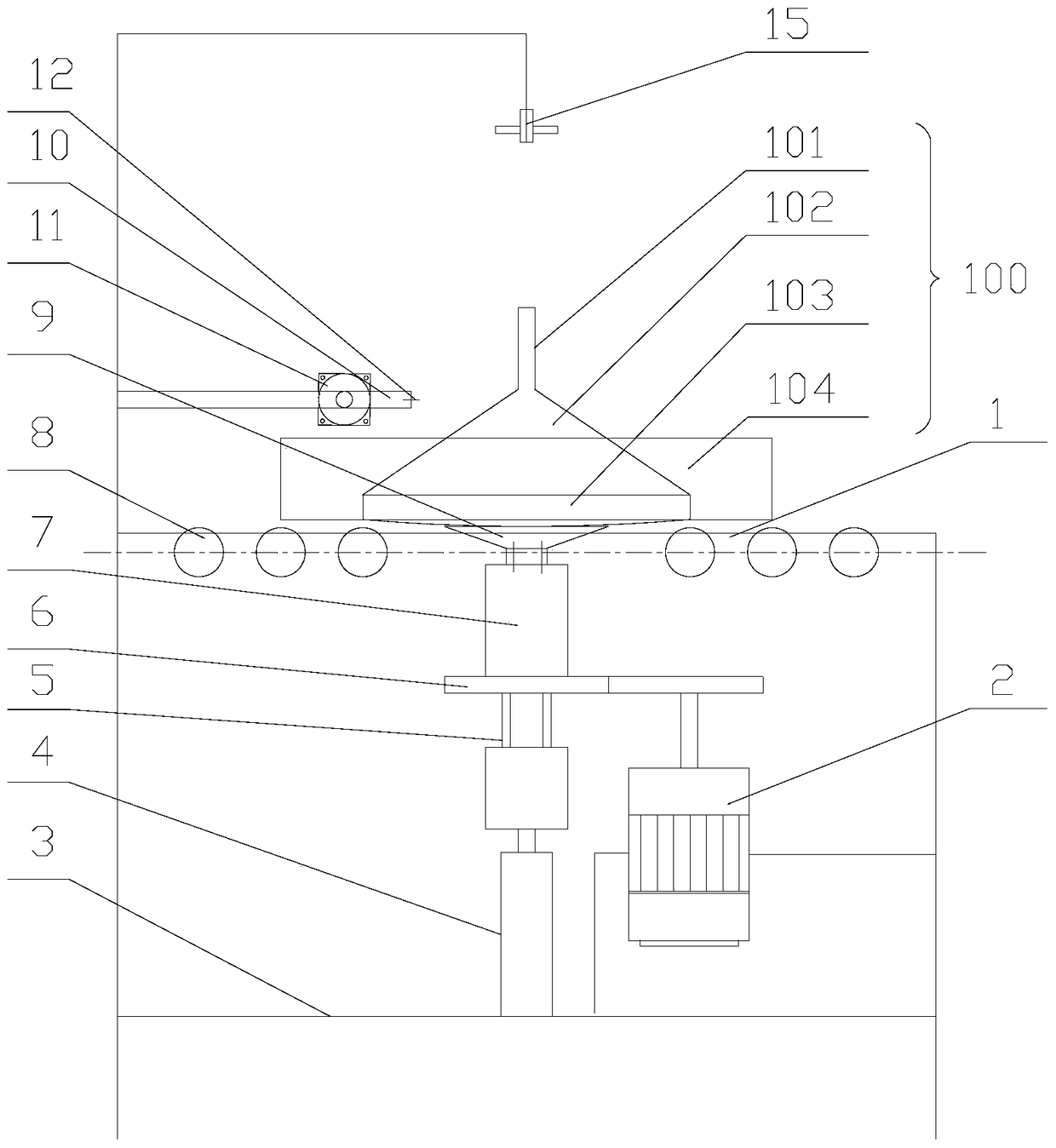

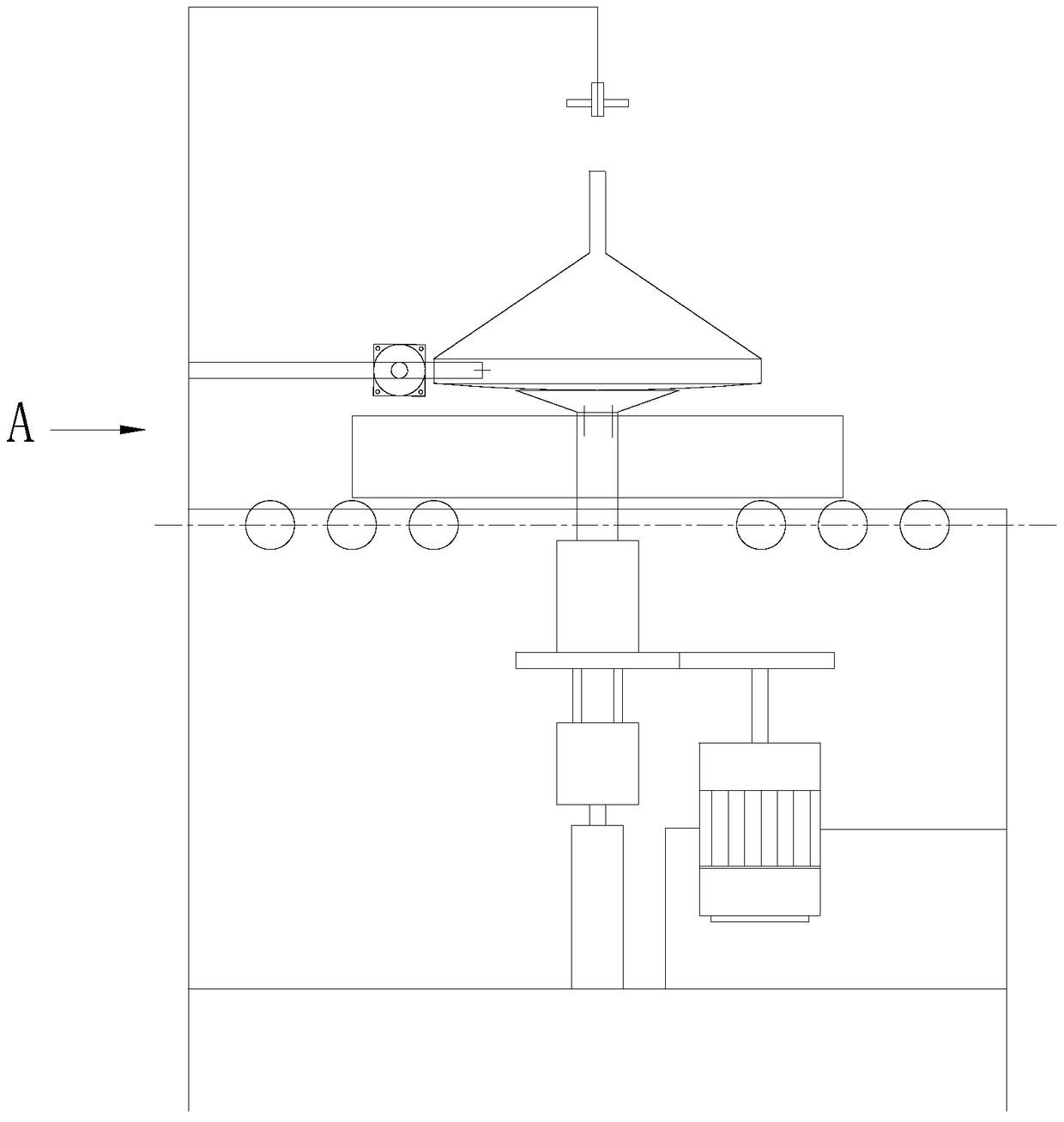

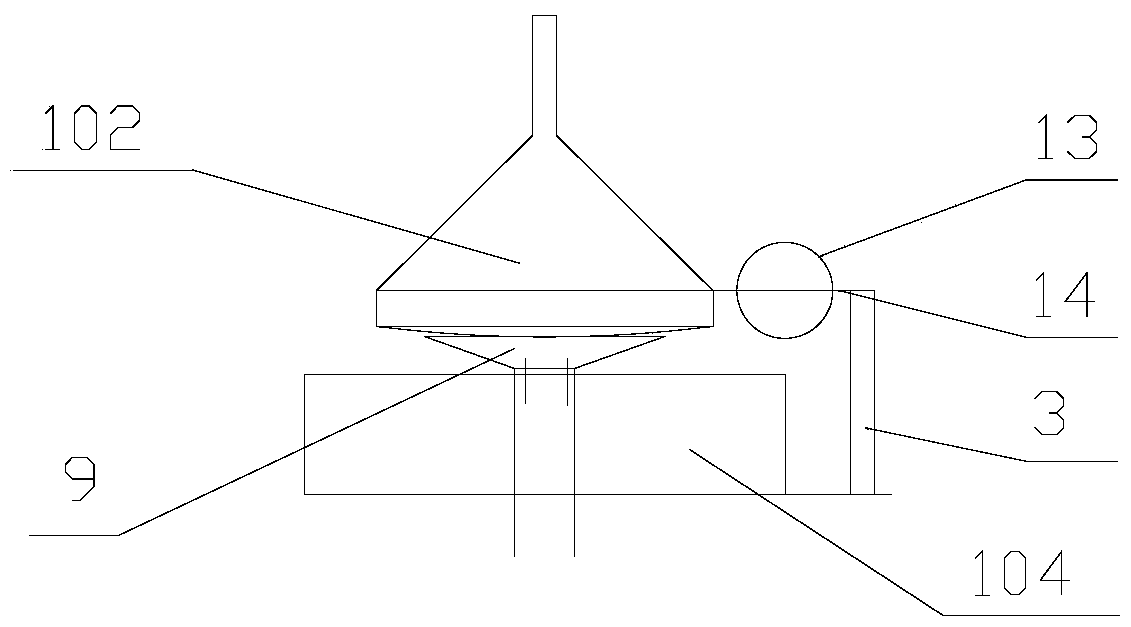

[0021] Aiming at the status quo of the prior art, the present invention proposes a dismantling equipment for a CRT display device, see attached Figure 1-2 , which includes a front shell separation module, wherein the front shell separation module includes a support mechanism 1 for placing a CRT display device (such as a CRT TV or a CRT computer monitor) 100 to be disassembled and for pushing up the display components 102 is a pushing mechanism for separating the display part 102 from the front case 104 , the supporting mechanism 1 is fixed to the frame 3 , and the pushing mechanism is fixed to the frame 3 under the supporting mechanism 1 .

[0022] During specific work, the CRT display device 100 is placed on the support mechanism 1 with the screen facing down. The support mechanism 1 may include two parallel support beams, or a plate-shaped support member with a hole in the middle. The display part 102 can be separated from the front case 104 by pushing up the screen part of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap