The installation structure of the manipulator claw piece of the tire vulcanizing machine

A technology for manipulator claws and tire vulcanization, which is applied in the direction of manipulators, chucks, manufacturing tools, etc. It can solve the problems of affecting the installation of claws and increasing the overall manufacturing cost of vulcanizing machines, and achieves low installation and manufacturing costs, efficient installation methods, and efficient installation methods. simple and effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

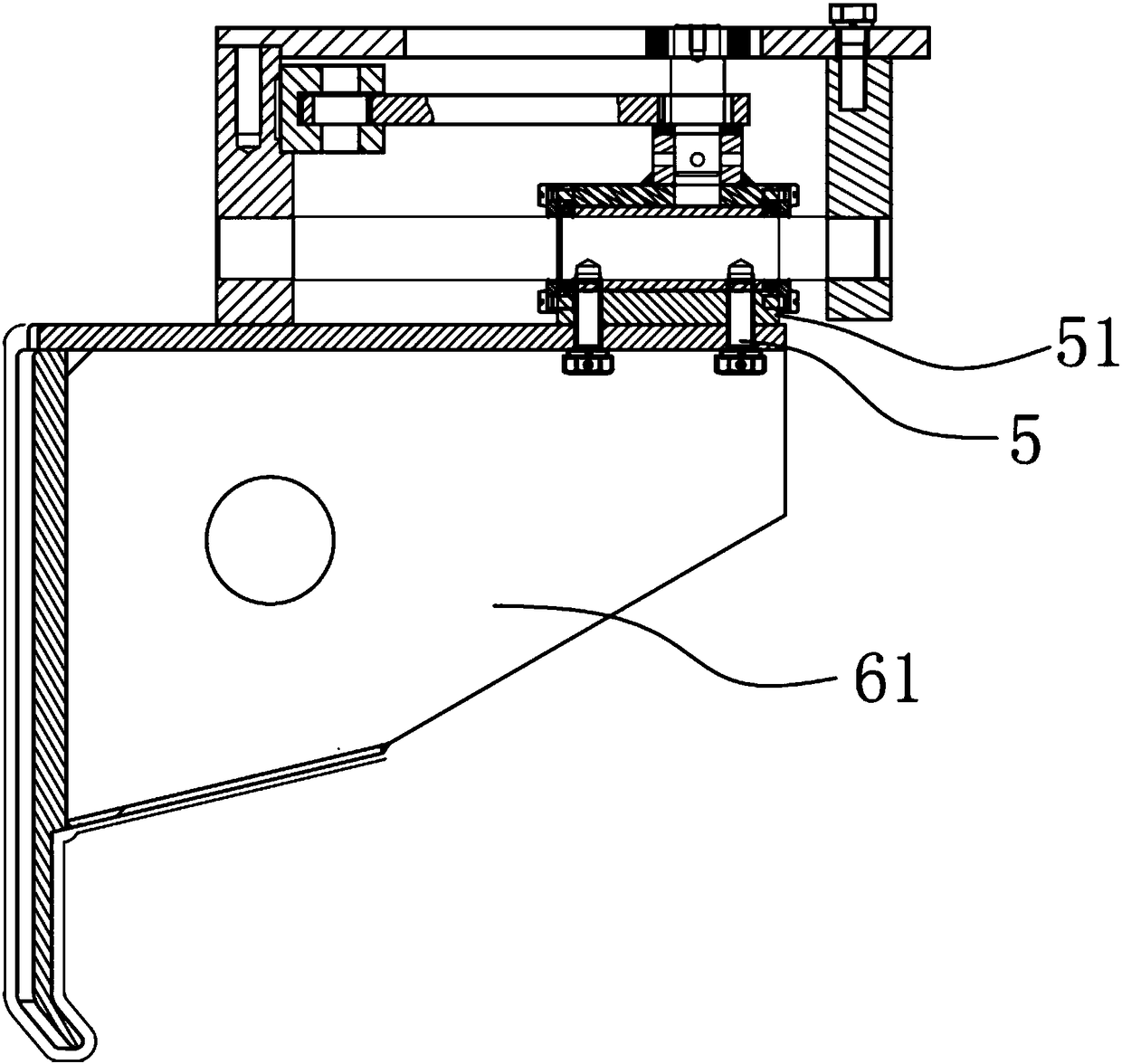

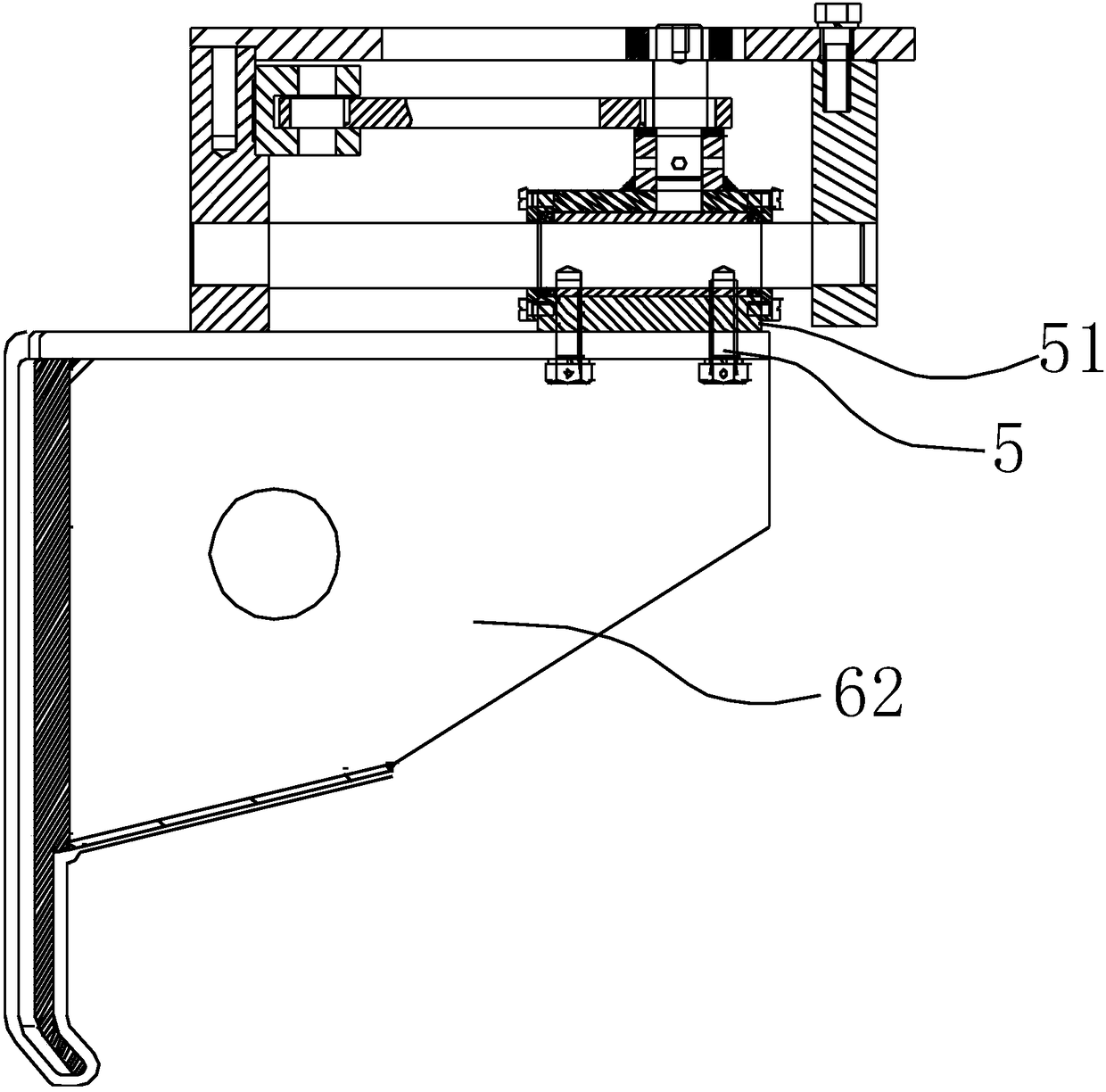

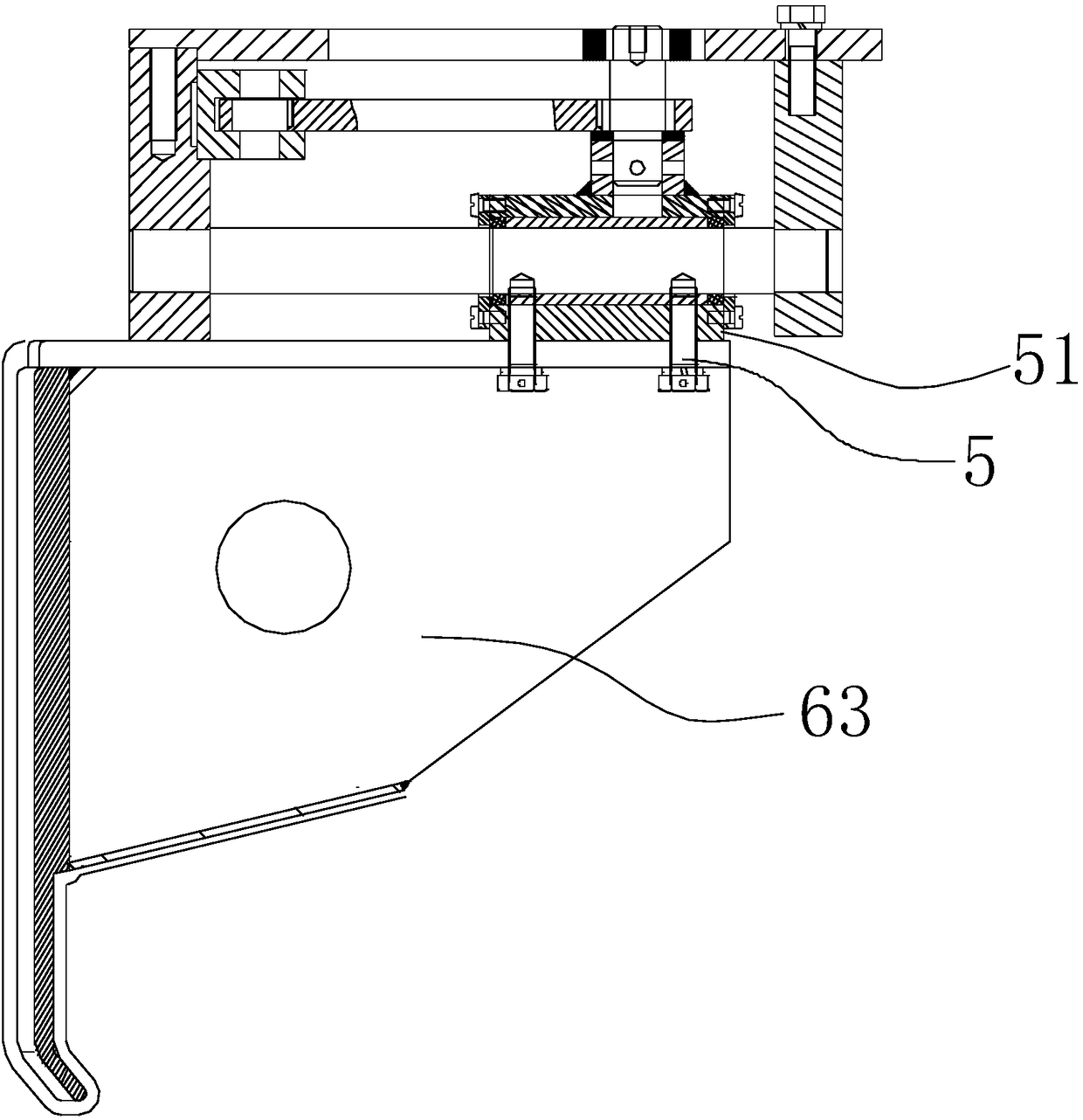

[0036] In order to achieve the purpose of the present invention, as Figure 5-9 As shown, in some embodiments of the installation structure of the manipulator claws of the tire vulcanizing machine of the present invention, an installation base 1 is provided, and a claw 2 is installed on the installation base 1, and the installation base 1 and the claws 2 Sliding fit is used. The specific installation base 1 can have a T-shaped protrusion 12, and a T-shaped groove 22 is opened on the claw piece 2 corresponding to the T-shaped protrusion 12 to form the sliding fit. In addition, it can also be used Other forms of sliding fit, such as sliding fit in the form of a dovetail groove, etc., the mounting base 1 and the claw piece 2 also have a first connecting portion 11 and a second connecting portion 21 that are detachably connected to each other, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com