A card automatic laminating machine

A laminator, automatic technology, applied in the direction of lamination, lamination device, lamination auxiliary operation, etc., can solve the problems of limited service life of the conveyor belt, high failure rate and defective rate, work in high temperature environment, etc., to achieve cost Low cost, extended service life, and the effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

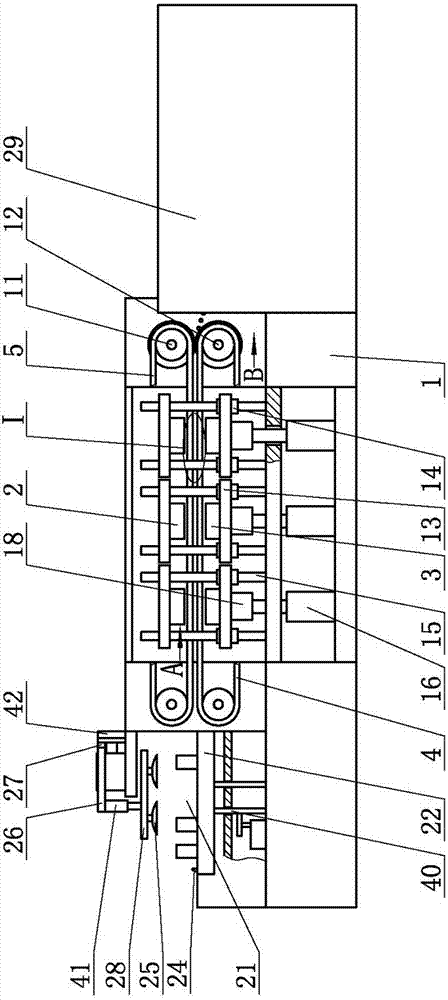

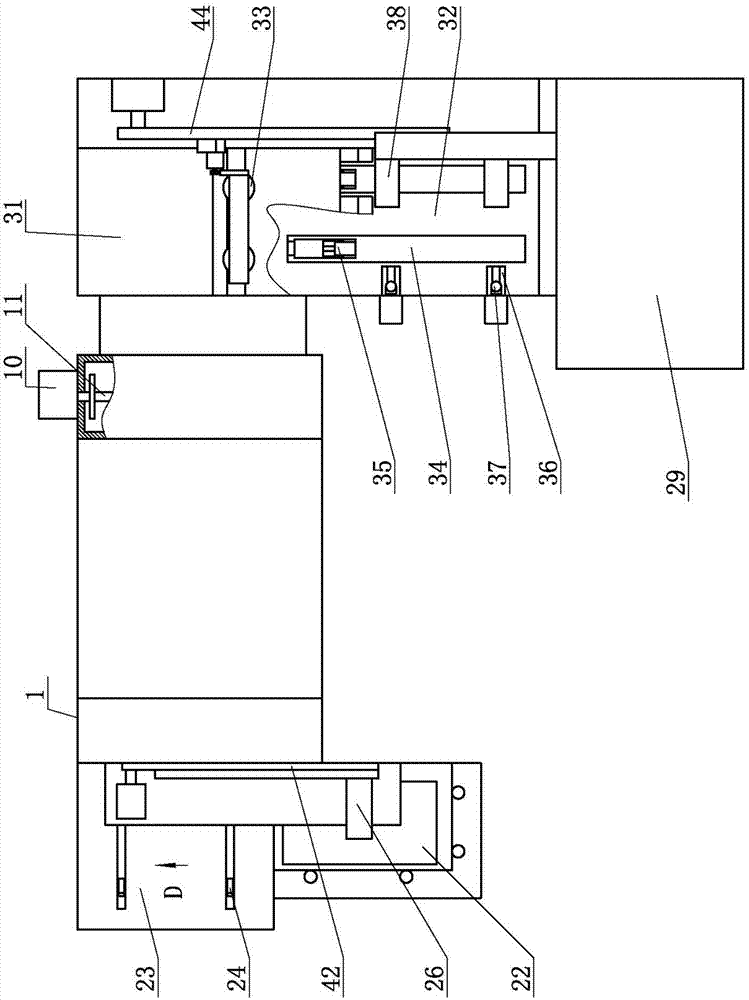

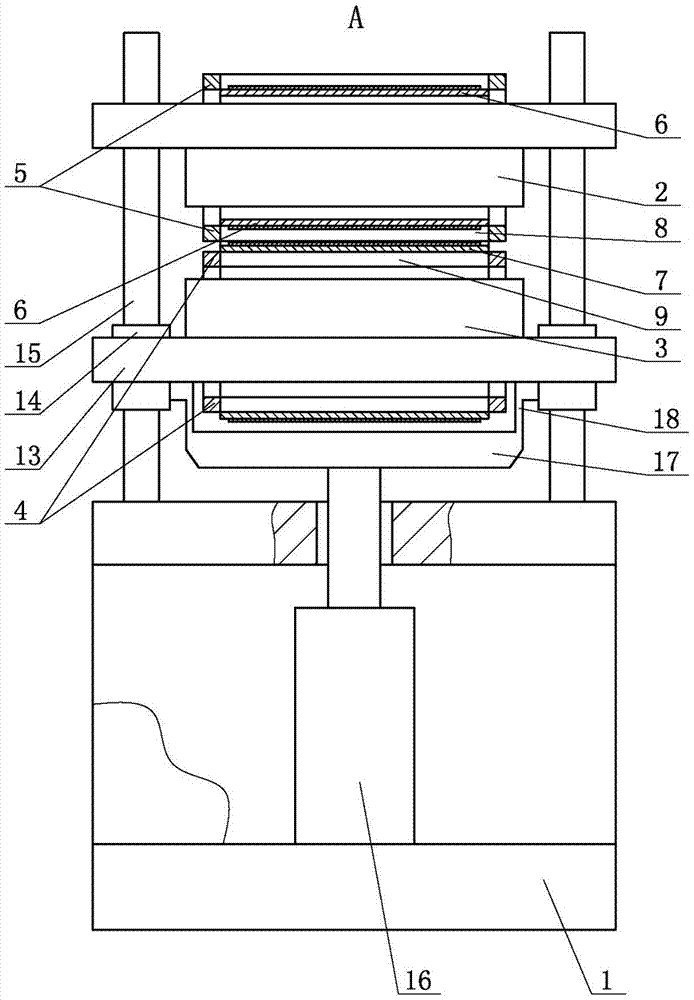

[0014] A card automatic laminating machine according to the present invention includes a frame 1, which is characterized in that: an automatic feeding device is installed at one end of the frame 1, and at least 2 sets of indenters are installed on the frame 1, and each set of indenters includes an upper press The head 2 and the lower pressure head 3, the upper pressure head 2 and the lower pressure head 3 can be pressed together, the lower pressure head 3 is a movable pressure head, and the lower pressure head 3 is installed on the movable plate 13, and the movable plate 13 passes through the sliding sleeve 14 cooperates with the guide column 15 on the frame 1, the upper pressure head 2 is a fixed pressure head, the upper pressure head 2 is fixedly connected with the frame 1 or the guide column 15, and the bottom of the movable plate 13 is connected with the hydraulic cylinder 16 through the connecting frame. Piston rod connection, the connecting frame includes a horizontal bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com