A pre-mixed abrasive water jet abrasive recycling system and its application method

A pre-mixing abrasive and circulation system technology, which is applied in the direction of abrasive feeding device, used abrasive processing device, abrasive, etc., can solve the problems of safety impact, abrasive tank cannot realize continuous feeding, product precision fluctuation, etc. , to achieve the effect of continuous cycle feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

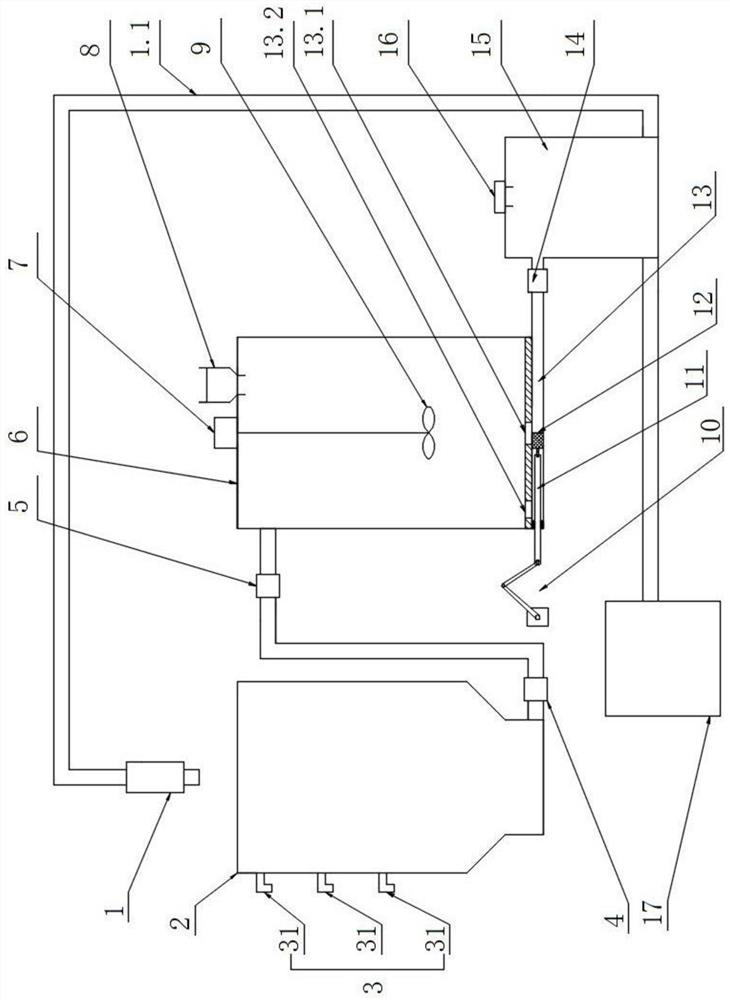

[0025] Such as figure 1 As shown, an abrasive recovery circulation system of a pre-mixed abrasive water jet includes a water tank 2 arranged below the nozzle 1, and the water tank 2 can catch the water and abrasive sprayed from the nozzle 1; the side wall of the water tank 2 An overflow device 3 is provided. Under the impact of the jet, the abrasive deposited in the water tank 2 floats up to a certain height, and a certain proportion of the abrasive and a larger proportion of water can be transferred through overflow pipes 31 of different heights in the overflow device 3. discharge. The overflow device can screen out the smaller abrasive particles to a certain extent because the larger abrasive particles are not easy to float to a higher height. A detachable vibrating screen 4 is connected to the bottom of the water tank 2, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com