Chassis for AGV having suspension mechanism

A suspension mechanism and vehicle technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of unstable chassis shaking, lack of chassis, space size restrictions, etc., to avoid the suspension of driving wheels, structure Simple and compact, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

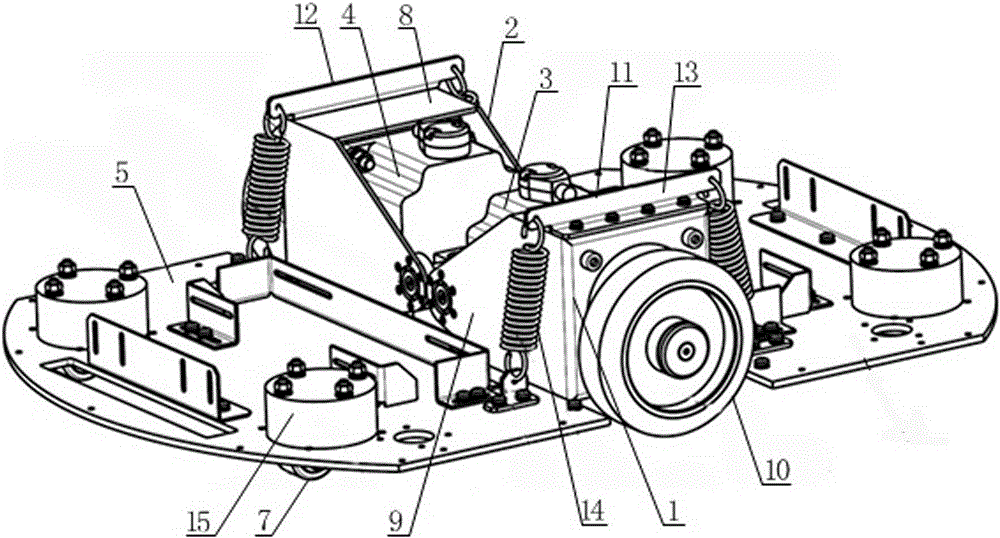

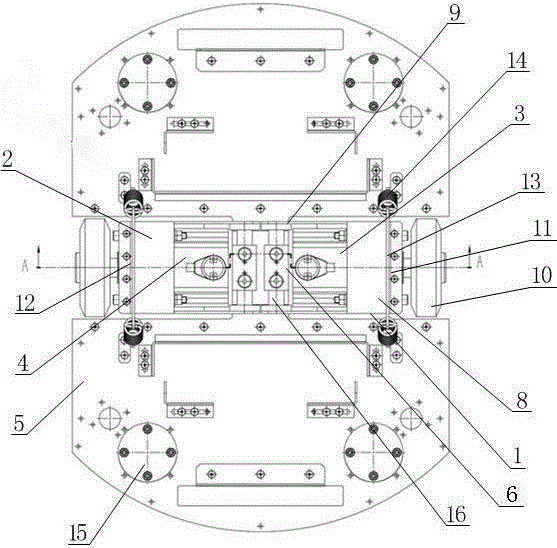

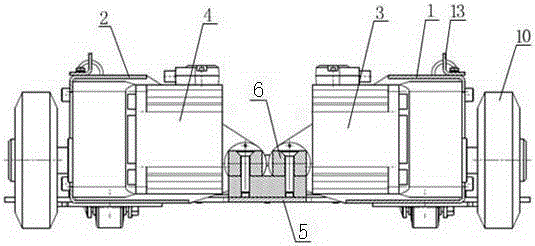

[0015] Such as Figure 1-4 Shown, a kind of AGV vehicle chassis with suspension mechanism, it comprises motor mounting bracket I1, motor mounting bracket II2, drive motor I3, drive motor II4 and AGV vehicle base plate 5, the top surface of base plate 5 middle part is provided with installation Block 6, the four corners of the bottom surface of the base plate 5 are equipped with universal wheels 7, the motor mounting bracket I1 and the motor mounting bracket II2 are all arranged in the middle of the base plate 5, and the motor mounting bracket I1 and the motor mounting bracket II2 are set On both sides of the mounting block 6, the motor mounting bracket I1 and the motor mounting bracket II2 are arranged symmetrically. Both the motor mounting bracket I1 and the motor mounting bracket II2 are composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com