Frame turnover device for frame packing machine

A technology of turning device and framing machine, which is applied in the direction of conveyor objects, transportation and packaging, etc., and can solve problems such as affecting the effect of framing and position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments.

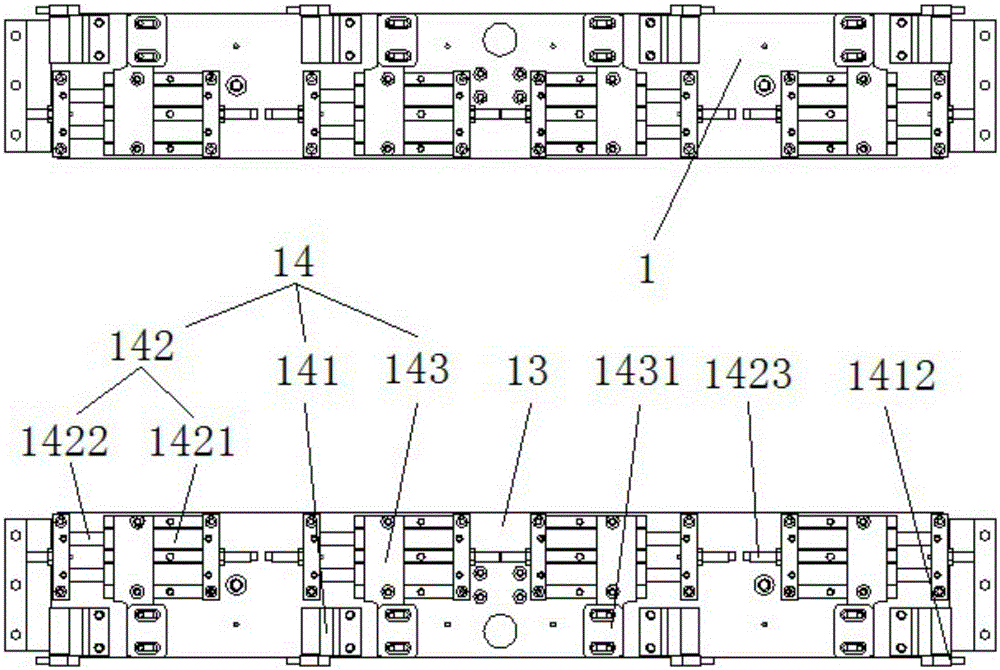

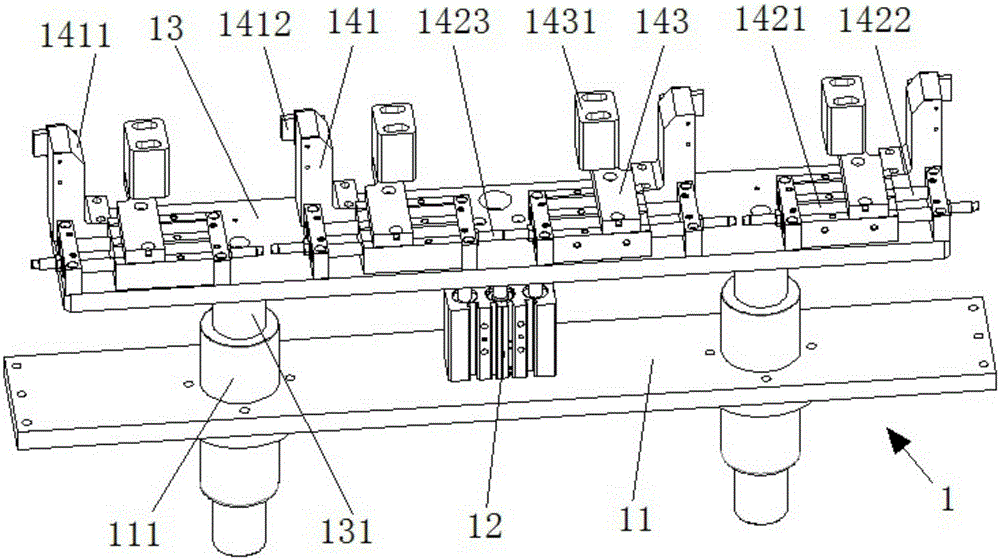

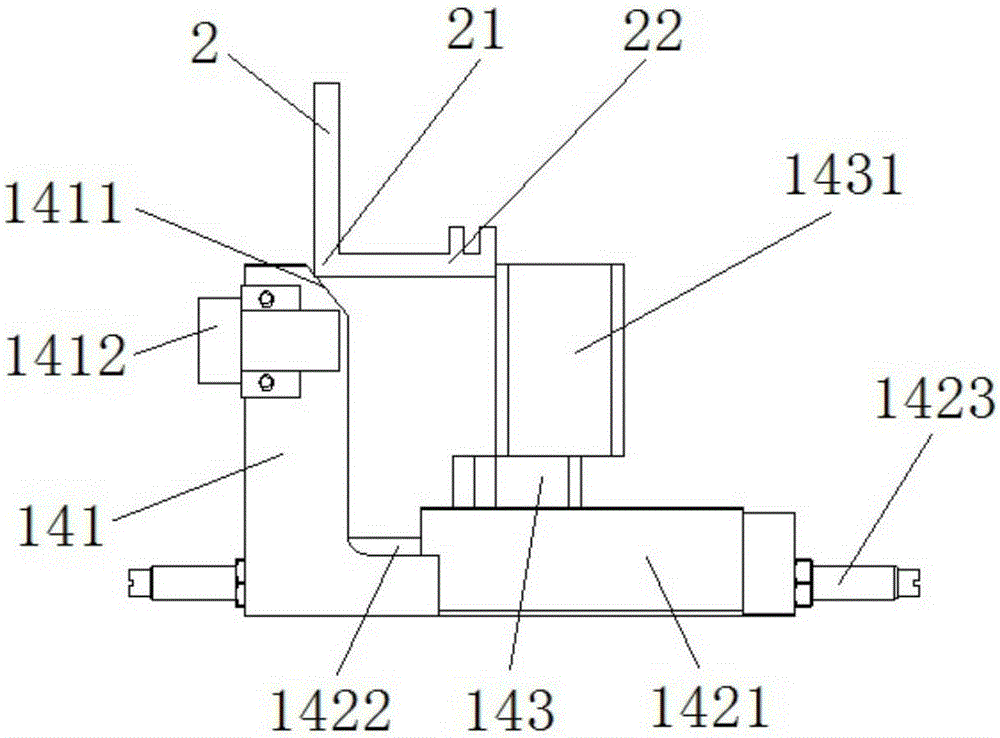

[0021] Such as figure 1 and figure 2 As shown, a frame overturning device for a frame loading machine of the present invention includes a pair of overturning mechanisms 1 arranged symmetrically. Lifting platform 13 and four sets of symmetrical clamping units 14 located above lifting platform 13, each clamping unit 14 includes static jaws 141 fixed on lifting platform 13 and clamping jaw cylinder 142 and is driven by clamping jaw cylinder 142 The movable jaw 143 and the upper inner side of the static jaw 141 are provided with a chamfered surface 1411 . Turning mechanism 1 sets up four frames 2 together from the gluing jig through the lifting of lifting cylinder 12, such as image 3 At this time, the corner 21 outside of the frame 21 meets the beveled surface 1411 and the glue-coated edge 22 naturally falls in the gap between the static jaw 131 and the movable j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com