A cutting machine for garment production

A slitting machine and garment technology, applied in the field of garment production, can solve the problems of low yield rate of fabrics, deviation of fabric specifications, drop of fabric tension, etc., and achieve the effects of improving quality, high firmness and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

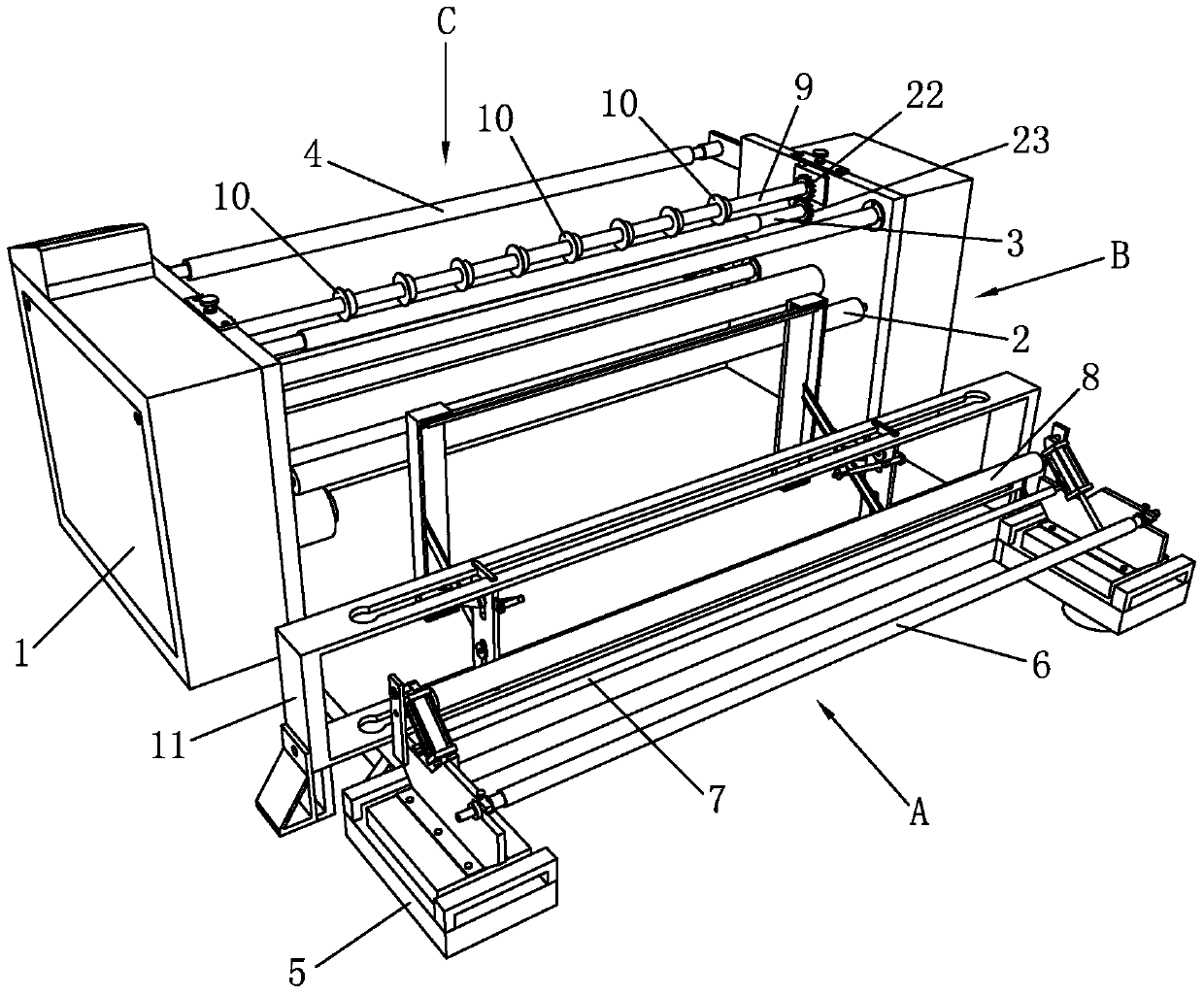

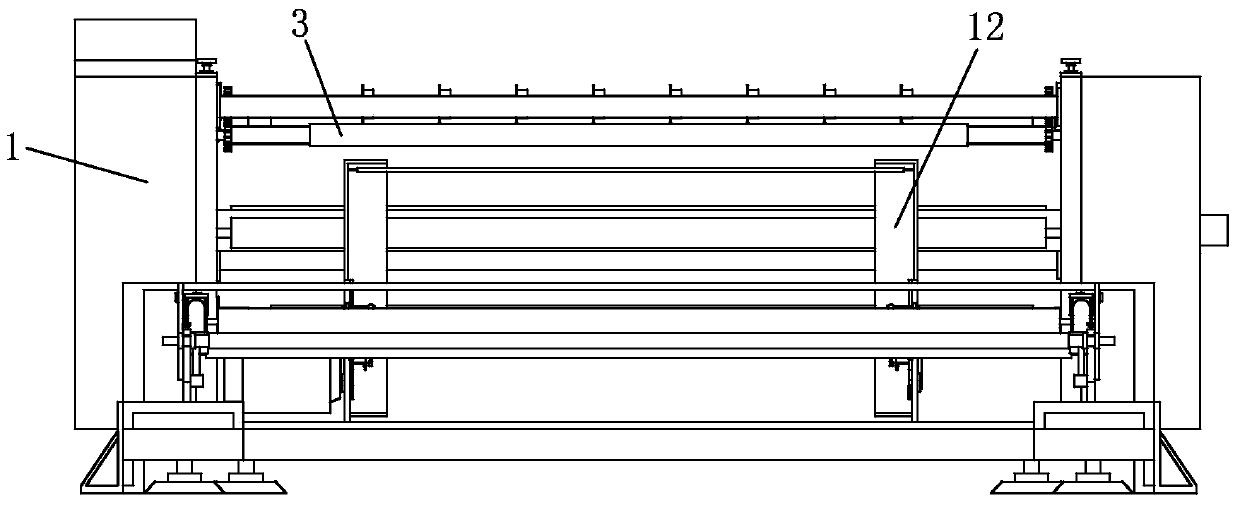

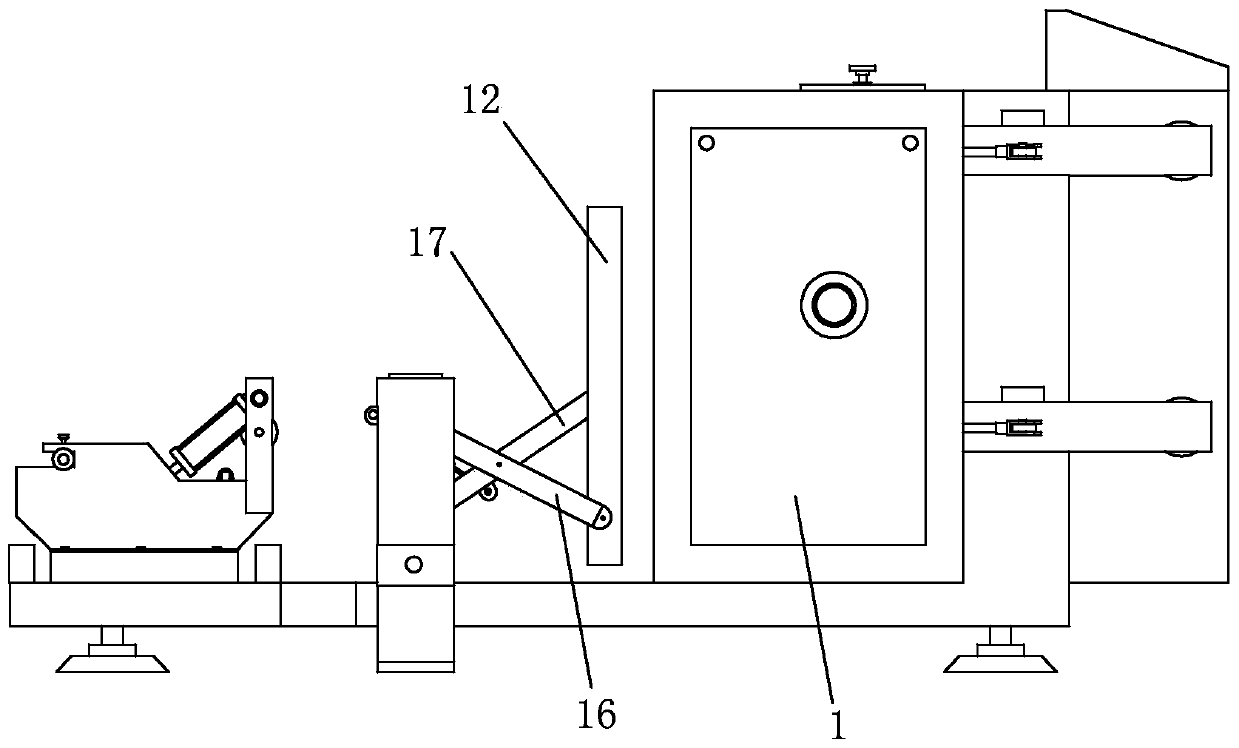

[0024] Such as Figure 1 to Figure 6 Shown is a slitting machine for garment production according to the present invention, which includes a slitting machine frame 1, a conveying mechanism and a slitting mechanism. The slitting machine frame 1 is equipped with a cloth guiding roller 2, a cloth passing roller 3 and a cloth receiving roller 4. The cloth guiding roller 2 mainly pulls the cloth into the slitting machine frame 1, and the height generally set is the entire slitting machine frame 1. half of the height of the machine frame 1; the cloth passing roller 3 is mainly for the process of conveying the cloth, which is generally arranged below the slitting mechanism, and its setting height depends on the height set by the slitting mechanism; the cloth receiving roller 4 is mainly For rewinding the slit cloth, two upper and lower cloth rewinding rollers 4 are generally installed, the upper cloth rewinding roller 4 mainly rewinds the cloth in even positions after slitting, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com