Glue-jointing tool for large regulating sheet of paddle

An adjustment piece and gluing technology, applied in the direction of connecting components, mechanical equipment, etc., can solve the problems of low work efficiency, waste of resources and manpower, unstable state, etc., to improve work efficiency, reduce personnel waste, and reduce gluing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below.

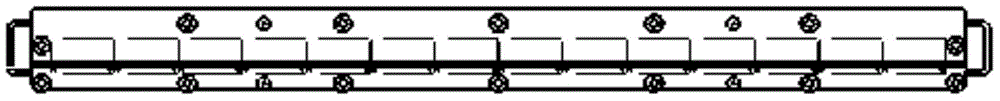

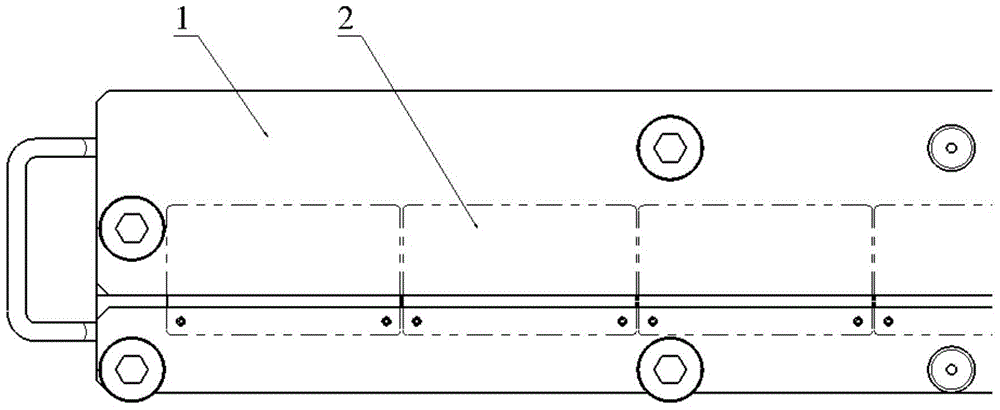

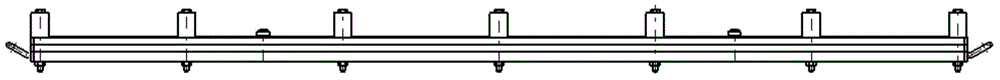

[0024] see figure 1 , the present invention blade large adjusting piece adhesive tooling, the upper mold body 1, the pressure plate 3, the mandrel 4, the main mold body 5, and the main mold body 5 are provided with a boss 16 for positioning the root of the adjustment piece, ensuring that 14 groups The flatness of the root of the large adjustment piece can meet the design requirements. The core mold 4 is set on the main mold body 5 and extends into the front of the adjustment piece to support the adjustment piece. The pressure plate 3 is arranged above the core mold 4 and covers the adjustment The top of the front part of the sheet is used to support the adjustment sheet when drilling. In addition, the boss (16) of the main mold body is provided with an upper mold body 1 covering the root of the adjustment sheet, which is used to apply pressure to the root of the adjustment sheet. 3. The mandrel 4 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com