Maintainable pressure gauge of spooler

A pressure gauge and winder technology, which is used in the measurement of fluid pressure, measurement devices, instruments, etc., can solve the problems of production impact, inaccuracy, and high instrument prices, and meet the needs of process index detection, easy operation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

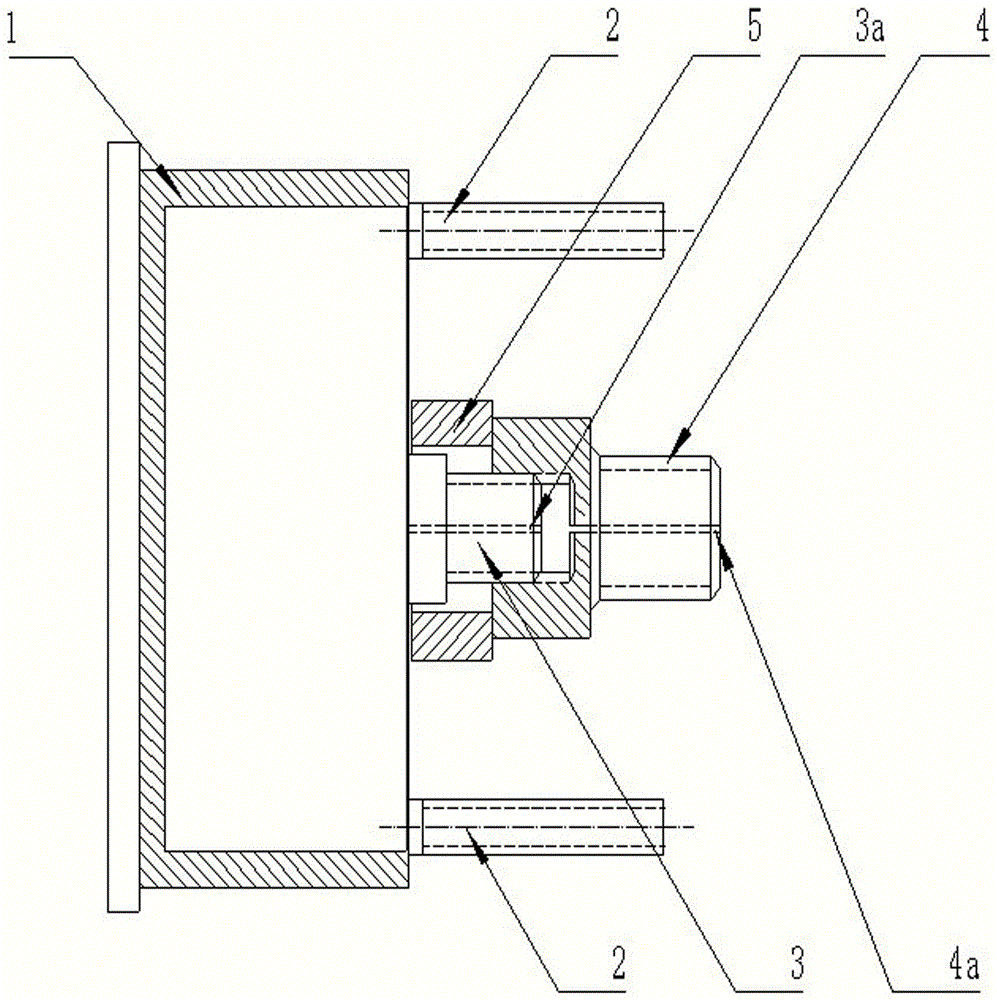

[0010] Below in conjunction with accompanying drawing, the present invention will be further described:

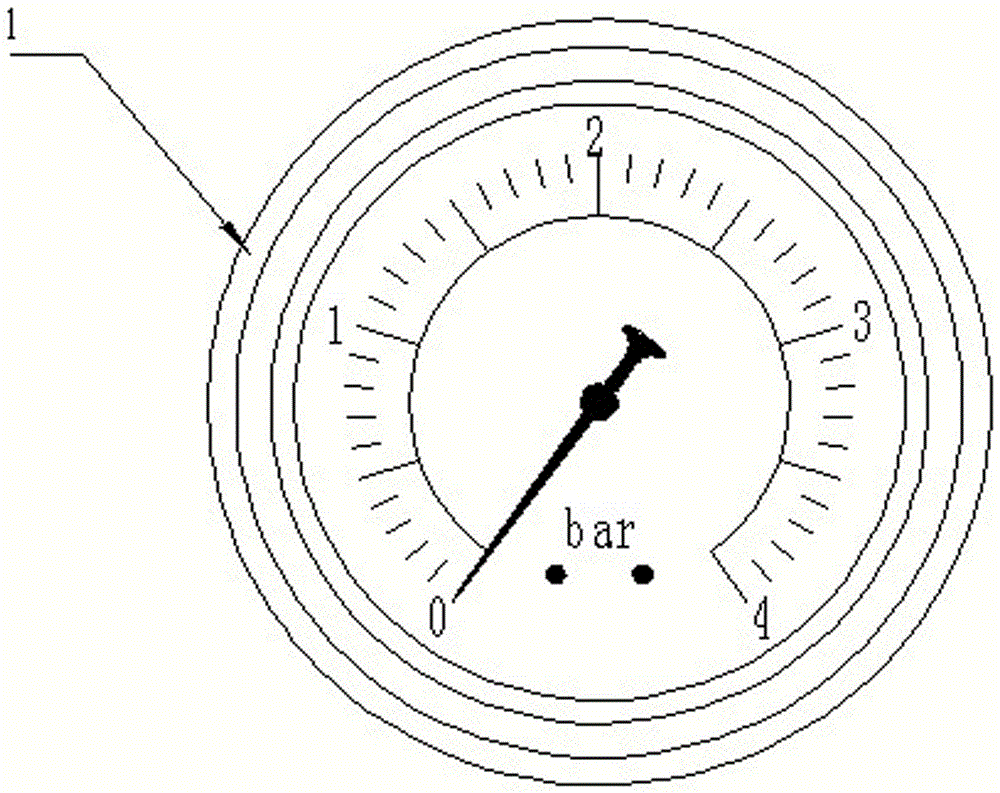

[0011] Such as figure 1 , figure 2 As shown, the present invention is a repairable winder pressure gauge, including a main pressure gauge 1, the main pressure gauge 1 has a number of limit screws 2 behind it, and the main pressure gauge 1 is also equipped with an air inlet port 3 behind it. And the limit ring 5, the air intake port 3 extends outside the limit ring 5 and is arranged in the limit ring 5, the air intake port 3 is connected to the conversion joint 4; the conversion joint 4 is provided with a rear air guide pipe 4a , The air intake port 3 is provided with a front air guide pipe 3a.

[0012] The inlet port 3 is centrally arranged behind the main pressure gauge 1 .

[0013] The air inlet port 3 is threadedly connected to one end of the conversion joint 4, and the other end of the conversion joint 4 is threaded to the gas external joint.

[0014] After the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com