Laser output control method and laser

A laser, laser technology, applied in the field of laser processing, can solve the problems of deformation of the processed object, high peak and power, long output time, etc., to achieve the effect of short output time and low energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

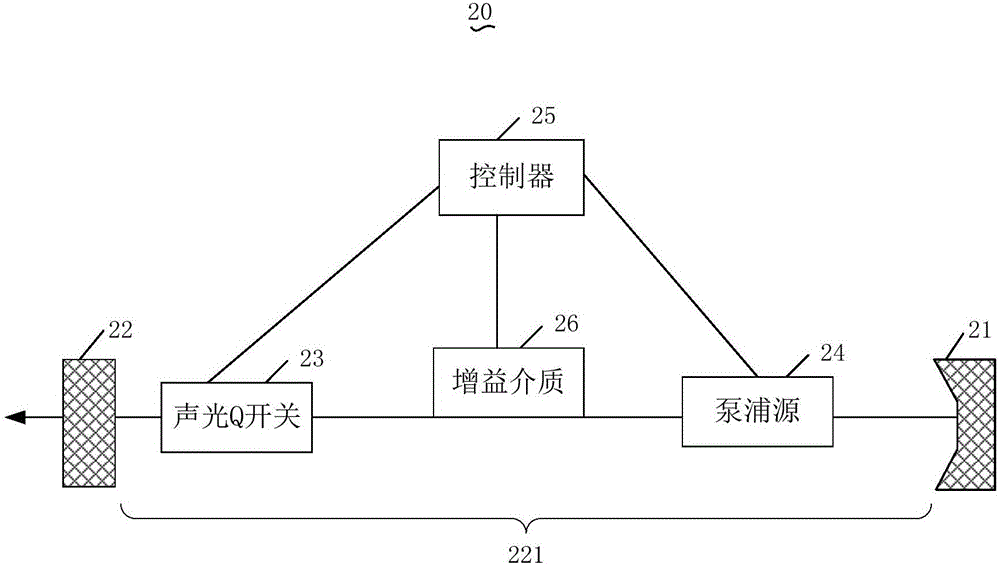

[0021] see figure 1 , the laser 20 includes a high reflectivity reflective fiber Bragg grating 21, a low reflectivity reflective fiber Bragg grating 22, an acousto-optic Q switch 23, a pump source 24, a controller 25 and a gain medium 26, a high reflectivity reflective fiber Bragg grating 21, a low reflectivity reflective fiber Bragg grating The reflective fiber grating 22 and the gain medium 26 form a resonant cavity 221, and the acousto-optic Q switch 23 and the pump source 24 are all arranged in the resonant cavity 221, and the controller 25 is connected with the acousto-optic Q switch 23, the pump source 24 and the gain medium 26 respectively. connect.

[0022] The pumping source 24 is used to input pumping light into the resonant cavity 221. The gain medium 26 is used for storing the pump light and accumulating the number of energy level invers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com