Iron tower cable support fixing device

A technology for cable brackets and fixing devices, applied in the direction of cable suspension devices, etc., can solve problems such as safety, inconvenience in construction, hidden dangers, etc., achieve the effects of enhancing stability, improving work efficiency and safety performance, and reducing construction difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

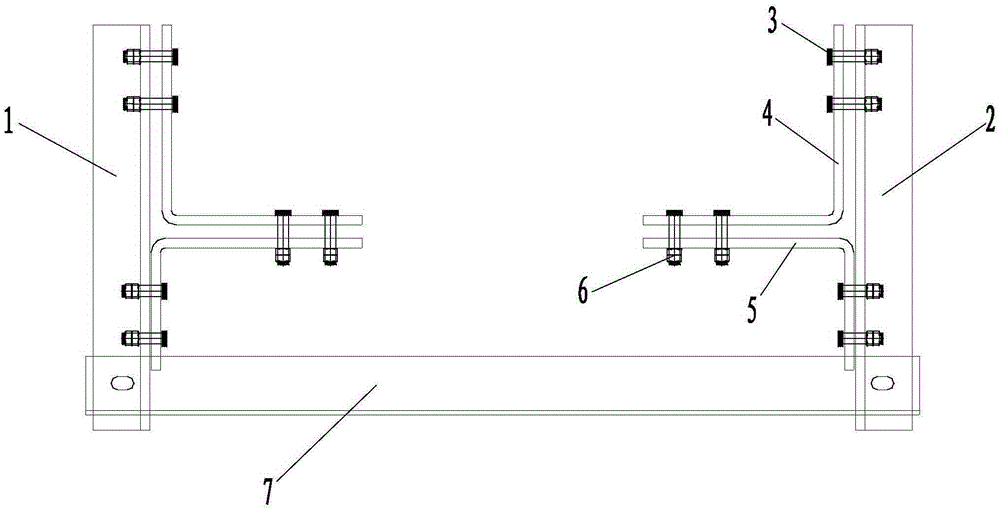

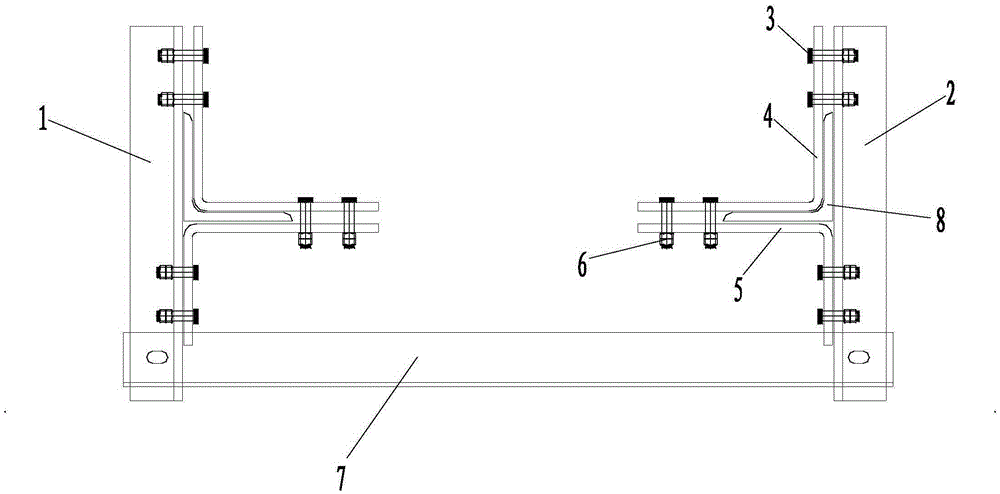

[0010] Such as figure 1 , 2 As shown, the present invention connects the first bent plate 4 and the second bent plate 5 through the first bolt 3 at the inner upper part and the lower part of the first connecting angle steel 1 and the second connecting angle steel 2 respectively, and the first bent plate The other end of the plate 4 and the second bent plate 5 are connected by a second bolt 6 , and the cable support angle steel 7 is connected between one end of the first connecting angle steel 1 and the second connecting angle steel 2 . Through the above settings, the present invention utilizes the first bending plate 4 and the second bending plate 5 to fix the first connection angle steel 1 and the second connection angle steel 2 on the tower body angle steel 8, and the cable support angle steel 7 can be connected to the iron tower body. Cables are effectively supported. The present invention can be fixed on any position of the angle steel 8 of the tower body, and the positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com