Disk wheel

一种车轮、盘式的技术,应用在辐板式车轮、车轮、轮毂等方向,能够解决螺栓紧固部变形、难以确保螺栓紧固部强度等问题,达到确保必要强度、抑制残留应力的影响的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

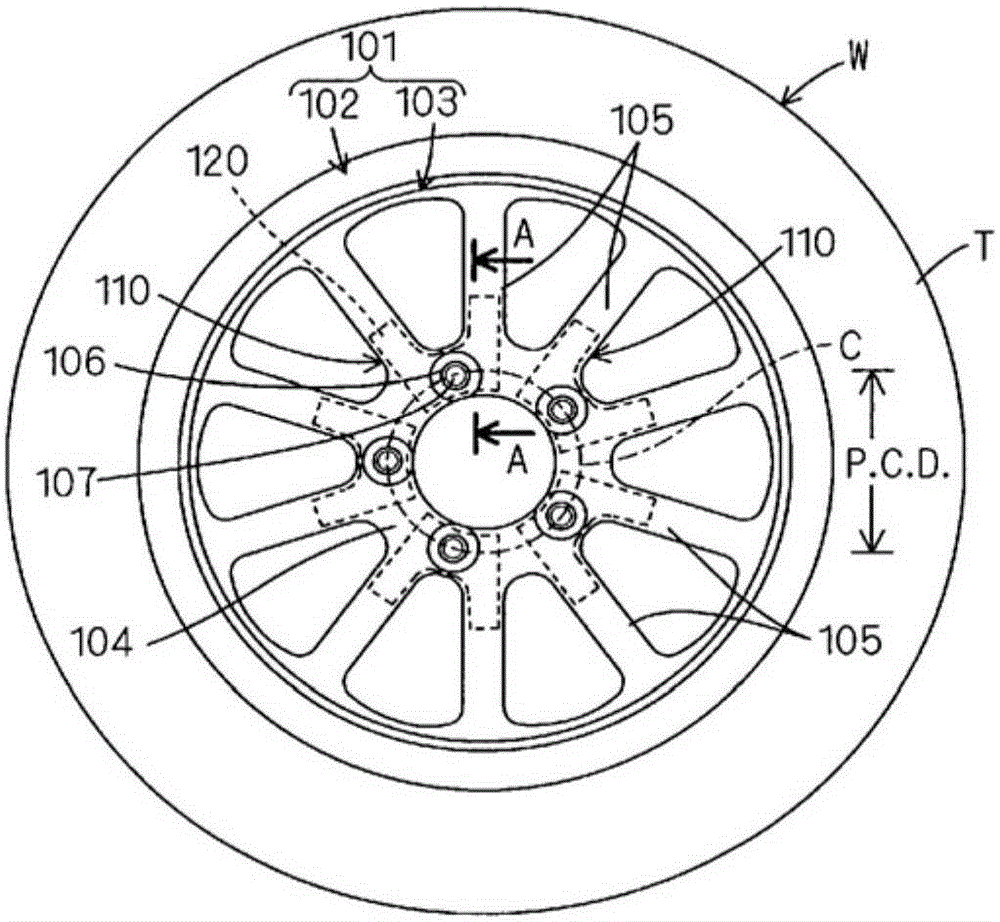

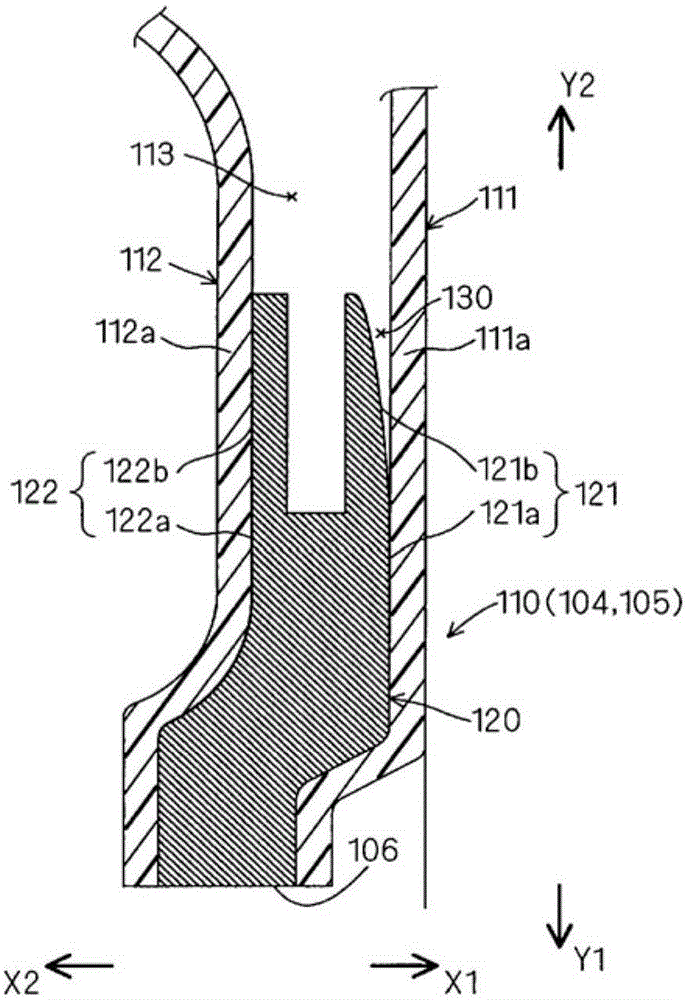

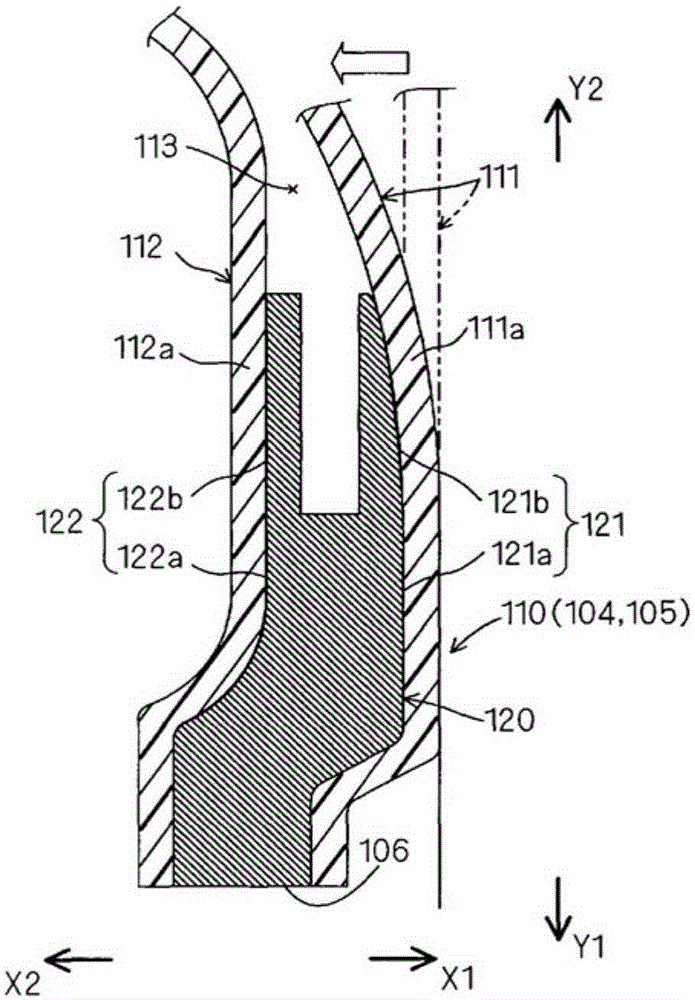

[0017] figure 1 A disc wheel 101 according to the present invention is shown in . By mounting a tire T on this disc wheel 101, a wheel W mounted on a vehicle is configured. The disc wheel 101 includes: a cylindrical rim 102 for holding a tire T; and a disc-shaped disc 103 joined to the rim 102 . That is, the disc wheel 101 has a so-called "one piece structure". The disk 103 further includes: a hub portion 104 attached to an axle hub (not shown); and spoke portions 105 radially protruding from the hub portion 104 . The disk 103 may be a type that does not include the spoke portion 105 . The hub portion 104 is provided with a plurality of bolt fastening portions 110 arranged annularly and coaxially along the circumferential direction of the disc 103 (circumferential direction of the disc wheel). Each bolt fastening portion 110 is provided with a bolt hole 106 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com