A push-and-reciprocate multi-hole valve

A reciprocating valve technology, applied in multi-way valves, valve details, valve devices, etc., can solve the problems of single-channel flow, can not meet the diversification of valves, and valves cannot realize multi-directional flow, etc., to achieve convenient control, Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

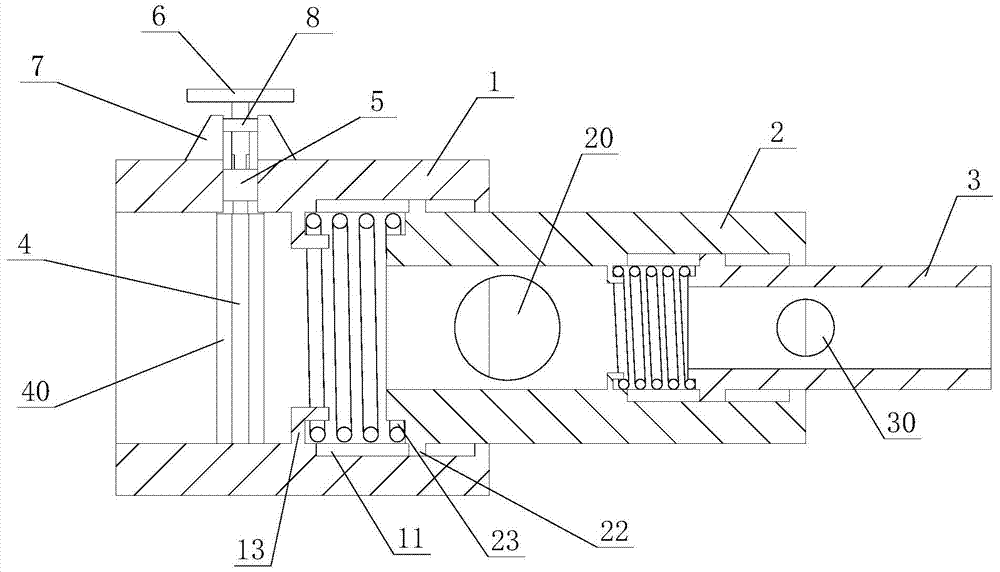

[0026] Such as figure 1 The shown one kind of pressing and reciprocating multi-hole valve includes the first pipeline 1, the second pipeline 2 and the third pipeline 3 whose pipe diameters successively decrease and are socketed. The first pipeline 1 is provided with a central rod 4 and a The valve disc 40 and the central rod 4 run through the first pipeline 1, and the central rod 4 located on the outer wall of the first pipeline 1 is connected to the handle 6. The rotation of the handle 6 drives the central rod 4 and the valve disc 40 to open and close, thereby controlling the first pipeline 1 On-off and flow rate of internal fluid. The fixing block 5 is used to maintain the position of the central rod 4 , and the seal 8 is used to improve the sealing between the first pipe 1 and the central rod 4 .

[0027] The second pipe 2 is slidably socketed in the first pipe 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com