Photographing lens

A camera lens and lens technology, used in the field of photography, can solve the problems of long size, difficult to match, and large exit angle of the main light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

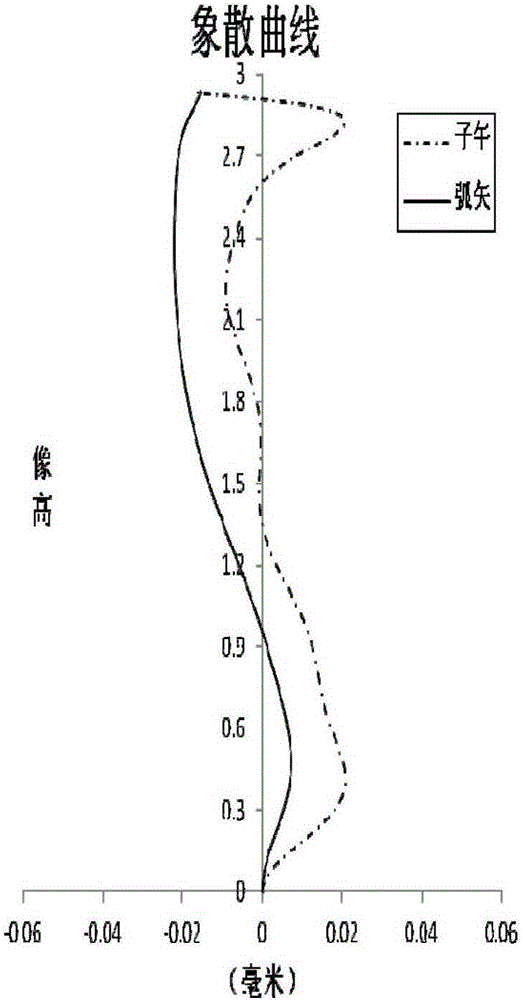

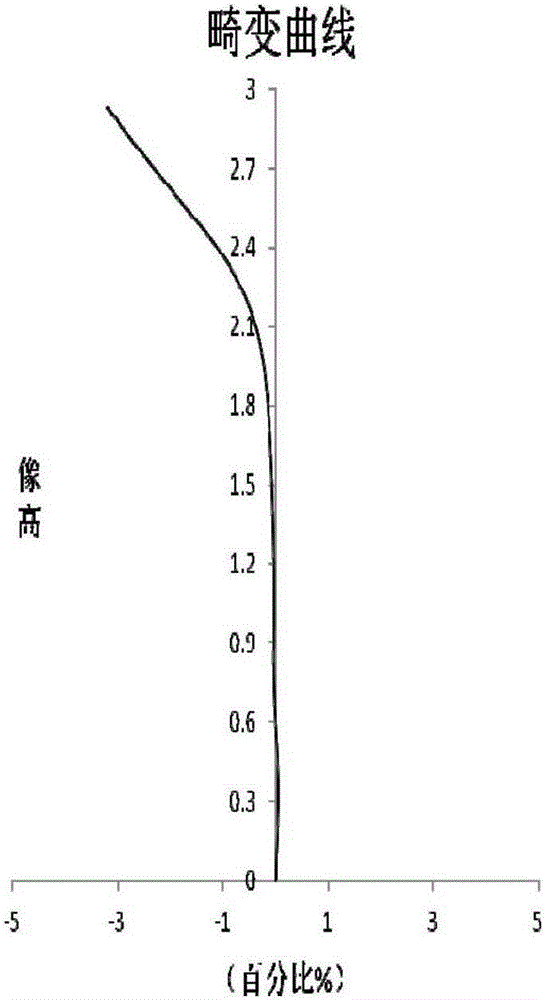

[0099] Please combine Figure 1 to Figure 5 , in embodiment 1, camera lens satisfies the condition of table 1 and table 2 below:

[0100] Table 1

[0101] surface number

surface type

radius of curvature

thickness

Refractive index / Abbe number

Conic coefficient

OBJ

sphere

infinity

500

--

--

STO

sphere

infinity

-0.1210

--

--

S1

Aspherical

1.8947

0.5787

1.544 / 56.11

0.0727

S2

Aspherical

8.4586

0.3349

--

-42.9715

S3

Aspherical

-12.7036

0.2520

1.651 / 21.52

-99.0000

S4

Aspherical

-9.8228

0.0300

--

-0.1103

S5

Aspherical

4.2726

0.2205

1.651 / 21.52

-99.0000

S6

Aspherical

2.5357

0.1440

--

-22.4375

S7

Aspherical

-3.9771

0.9354

1.544 / 56.11

-31.0304

S8

Aspherical

-0.8409

0.0306

--

-3.4069

...

Embodiment 2

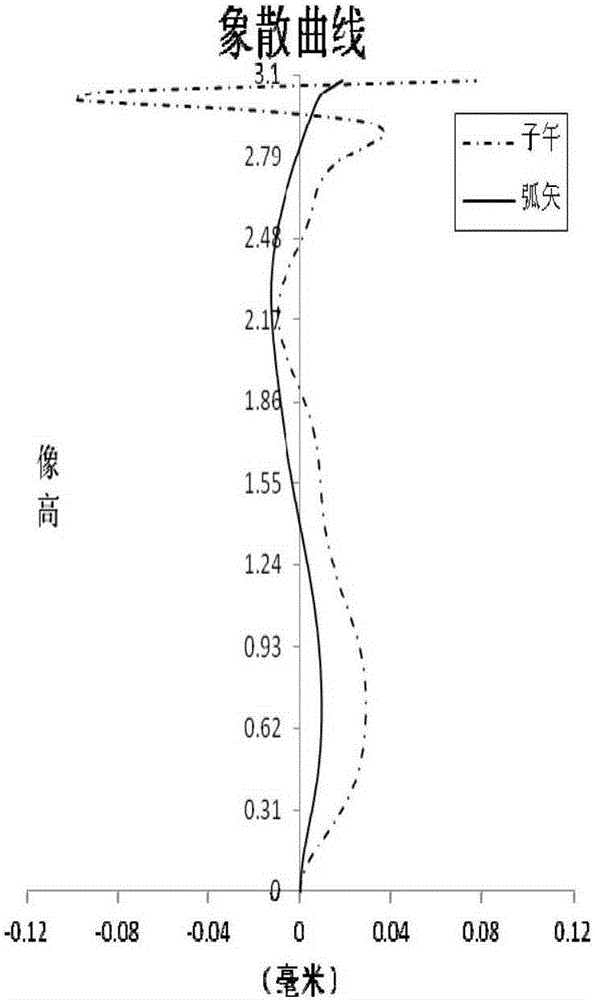

[0107] Please combine Figure 6 ~ Figure 10 , in embodiment 2, camera lens satisfies the condition of table 3 and table 4 below:

[0108] table 3

[0109] surface number

surface type

radius of curvature

thickness

Refractive index / Abbe number

Conic coefficient

OBJ

sphere

infinity

infinity

--

--

STO

sphere

infinity

-0.1210

--

--

S1

Aspherical

1.9192

0.5462

1.544 / 56.11

-0.1289

S2

Aspherical

8.0800

0.2943

--

-47.1424

S3

Aspherical

-14.6666

0.2537

1.651 / 21.52

-99.0000

S4

Aspherical

-11.3886

0.0301

--

3.2443

S5

Aspherical

3.5686

0.2441

1.651 / 21.52

-96.2349

S6

Aspherical

2.5356

0.1548

--

-23.1074

S7

Aspherical

-3.2688

0.9103

1.544 / 56.11

-30.2595

S8

Aspherical

-0.7420

0.0300

--

-3.81...

Embodiment 3

[0115] Please combine Figure 11 to Figure 15 , in embodiment 3, camera lens satisfies the condition of table 5 and table 6 below:

[0116] table 5

[0117] surface number

surface type

radius of curvature

thickness

Refractive index / Abbe number

Conic coefficient

OBJ

sphere

infinity

infinity

--

--

STO

sphere

infinity

-0.1059

--

--

S1

Aspherical

1.9384

0.5668

1.544 / 56.11

-0.0931

S2

Aspherical

9.6741

0.3045

--

-48.5808

S3

Aspherical

-10.6421

0.2601

1.651 / 21.52

-98.8459

S4

Aspherical

-12.3260

0.0300

--

-0.6800

S5

Aspherical

3.4990

0.2500

1.651 / 21.52

-88.1053

S6

Aspherical

2.4804

0.1471

--

-23.7094

S7

Aspherical

-3.7643

0.9208

1.544 / 56.11

-32.5927

S8

Aspherical

-0.7406

0.0300

--

-3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap