Shoe tree height manually adjusting device

A manual adjustment and shoe last technology, applied in footwear, shoe-making machinery, clothing, etc., can solve problems such as the unexplained mechanism of shoe last height adjustment and the great influence on the quality of processed shoes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

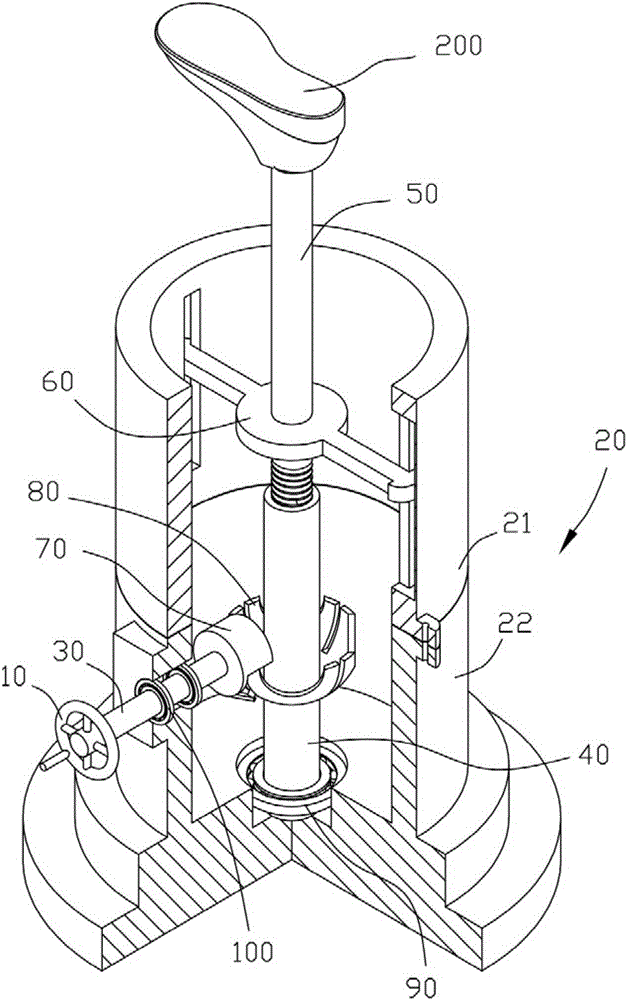

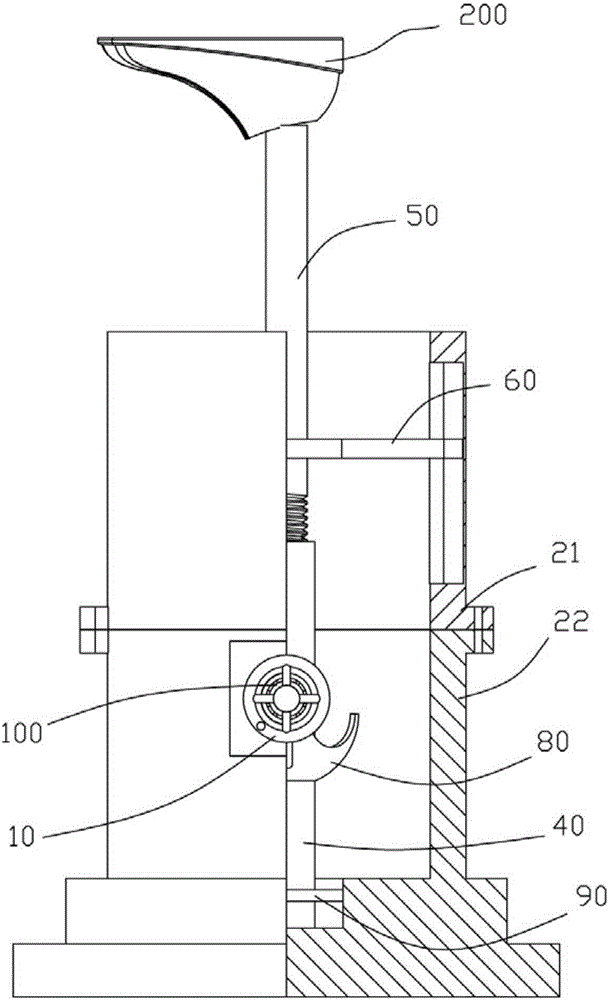

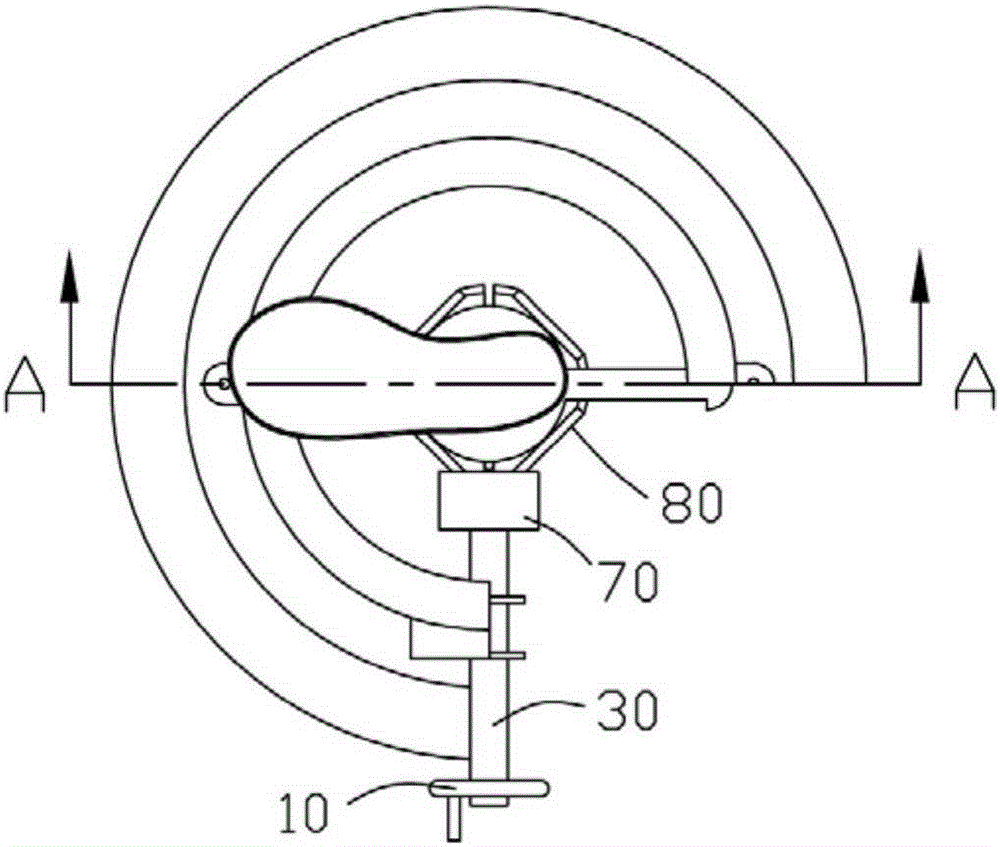

[0022] Such as Figure 1 to Figure 8 , a device for manually adjusting the height of a shoe last, comprising a vertically arranged cylindrical box 20, a rotating shaft 40 is arranged at the center of the box 20, a threaded rod 50 is installed on the upper part of the rotating shaft 40, and the rotating shaft 40 Screwed with the threaded rod 50, the top of the threaded rod 50 is equipped with a shoe last 200, the middle part of the threaded rod 50 is also fixedly connected with the stopper 60, the two ends of the stopper 60 are inserted into the inner wall of the box body 20, and Can carry out vertical movement; The bottom of described rotating shaft 40 is fixedly installed a spherical sheave 80, and the center line of described spherical sheave 80 coincides with the center line of rotating shaft 40, and the opening of spherical sheave 80 is upwards, The spherical sheave 80 meshes with a horizontally arranged sheave disc 70, and the sheave disc 70 is mounted on the end of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com