Segmented curve type lifting rib lining plate

A lifting rib and curved technology, applied to the field of mill discharge end liner, can solve the problems of reducing ore discharge efficiency, achieve the effects of reducing energy consumption, reducing costs, improving ore discharge efficiency and mill output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

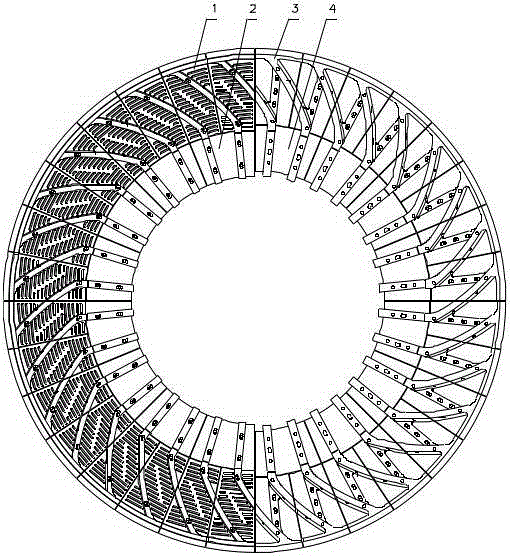

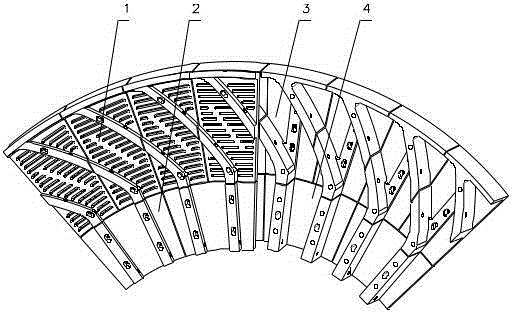

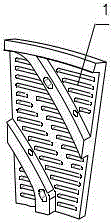

[0017] With reference to the attached drawings, a segmented curved lifting rib liner includes a grating board liner outer ring 1, a grating board liner inner ring 2, a dustpan liner outer ring 3, a dustpan liner inner ring 4, and a half The inner ring of the dustpan liner 3 and the inner ring 4 of the dustpan liner are fixed on the inner side of the discharge end cover of the self-mill and lattice ball mill, and the grating plate lining is fixed on the outer ring 3 of the dustpan liner and the inner ring 4 of the dustpan liner Plate outer ring 1, grid plate liner inner ring 2.

[0018] The lifting ribs of the outer ring 1 of the grating board lining board, the lifting ribs of the inner ring 2 of the grating board lining board, the lifting ribs of the outer ring 3 of the dustpan board lining board, and the lifting ribs of the inner ring 4 of the dustpan board lining board are in a segmented curve. And polyline.

[0019] The working principle of the segmented curved lifting rib lini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com