Trash can clamping device

A technology for a clamping device and a trash can, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of small clamping surface, insufficient clamping, easy to be clamped, etc. Flip function, improve clamping stability, increase the effect of clamping stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

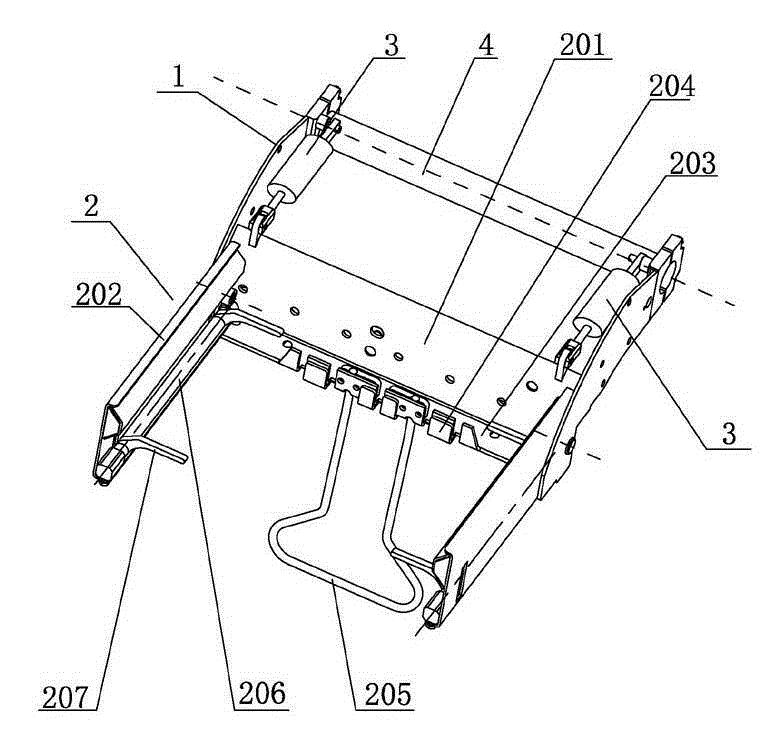

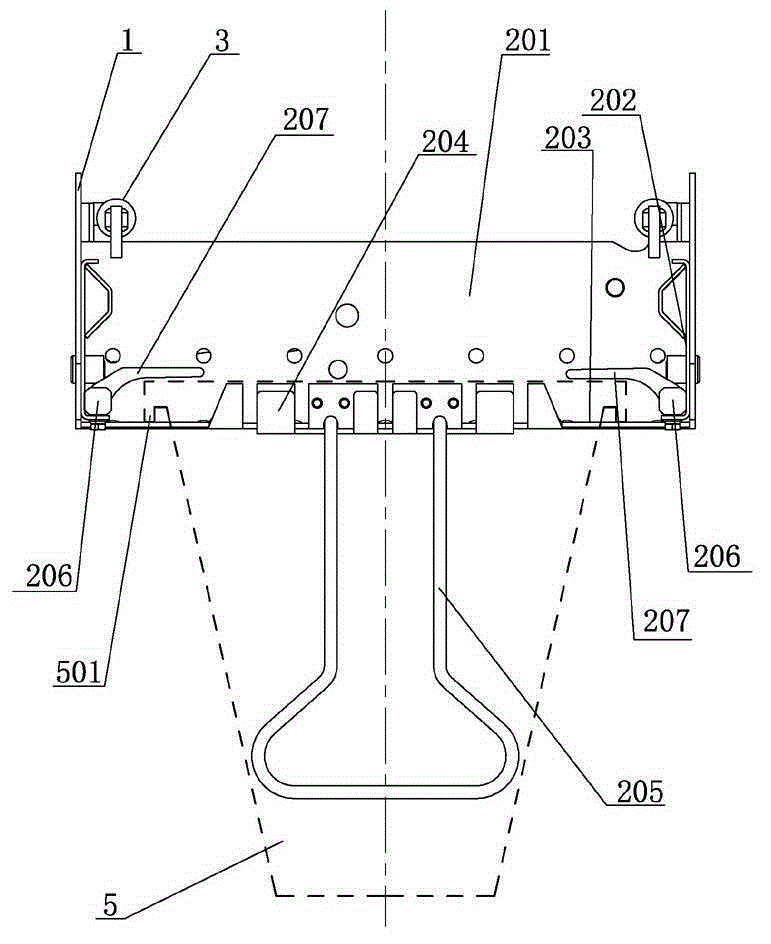

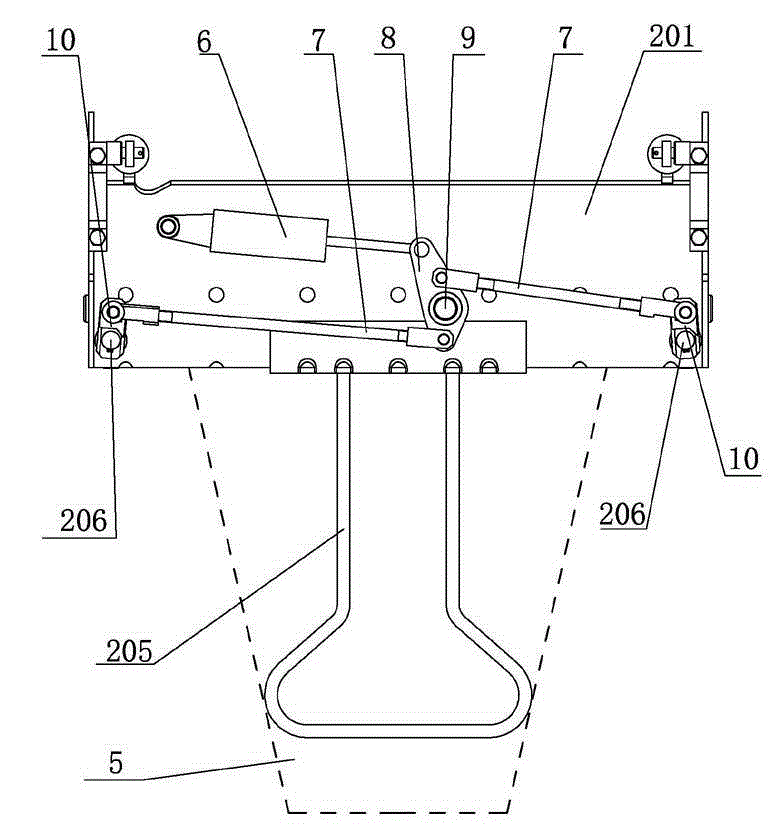

[0016] Such as Figure 1-5 As shown, a trash can clamping device includes a bracket 1 whose feet are fixedly set on the turning shaft 4, and also includes a turning frame 2 rotatably mounted on the head of the bracket 1, a turning cylinder 3, and a turning cylinder 3 The piston rod is hinged with the overturn frame 2, and the cylinder barrel of the overturn cylinder 3 is hinged with the support 1 foot.

[0017] The above-mentioned overturning frame 2 includes a front baffle 201 extending parallel to the overturning axis 4, and both ends of the front baffle 201 are provided with side baffles extending perpendicular to the overturning axis 4 and located on the clamping side of the front baffle 201. plate 202.

[0018] The lower end of the clamping side of the front baffle 201 is provided with a support platform 203 for supporting the barrel edge 501 , and the support platform 203 is provided with a limiting plate 204 for hooking the barrel edge 501 .

[0019] The lower side of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com