Thin-wall normal-section robot bearing

A frontal section and robot technology, applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems that the axial overturning moment bearing capacity has not been improved, and the bearing structure has not been greatly improved, so as to achieve light weight and space occupation. The effect of lower ratio and lower self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will be combined with the accompanying drawings in the embodiments of the present invention, the technical solution in the embodiments of the present invention will be described clearly and completely, it is clear that the embodiments described are only a part of the embodiment of the present invention, not all embodiments. Based on embodiments in the present invention, all other embodiments obtained by those of ordinary skill in the art without making creative work, are within the scope of protection of the present invention.

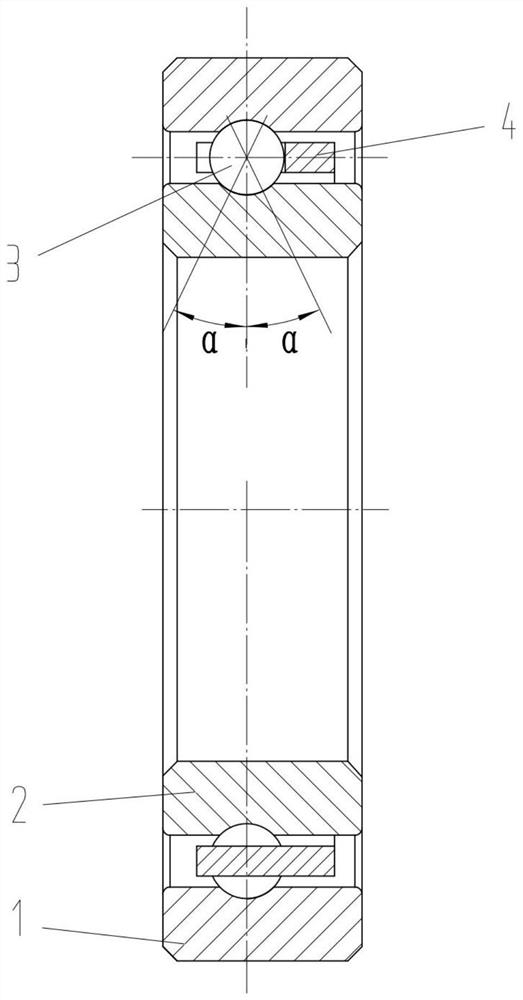

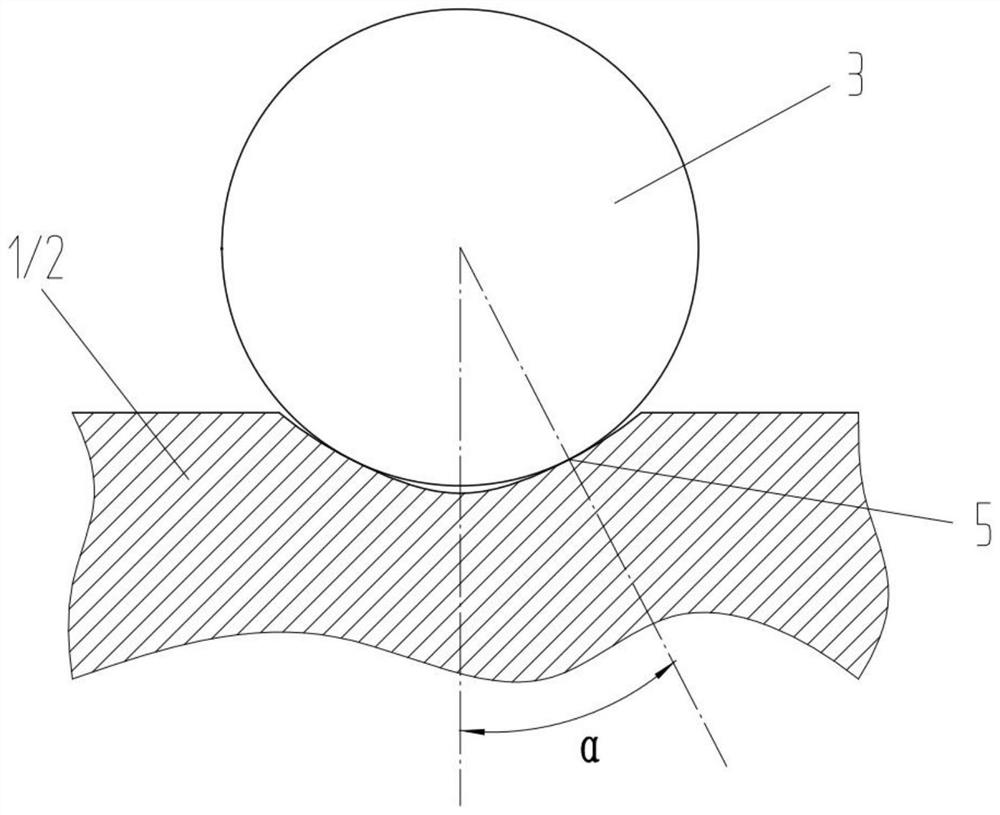

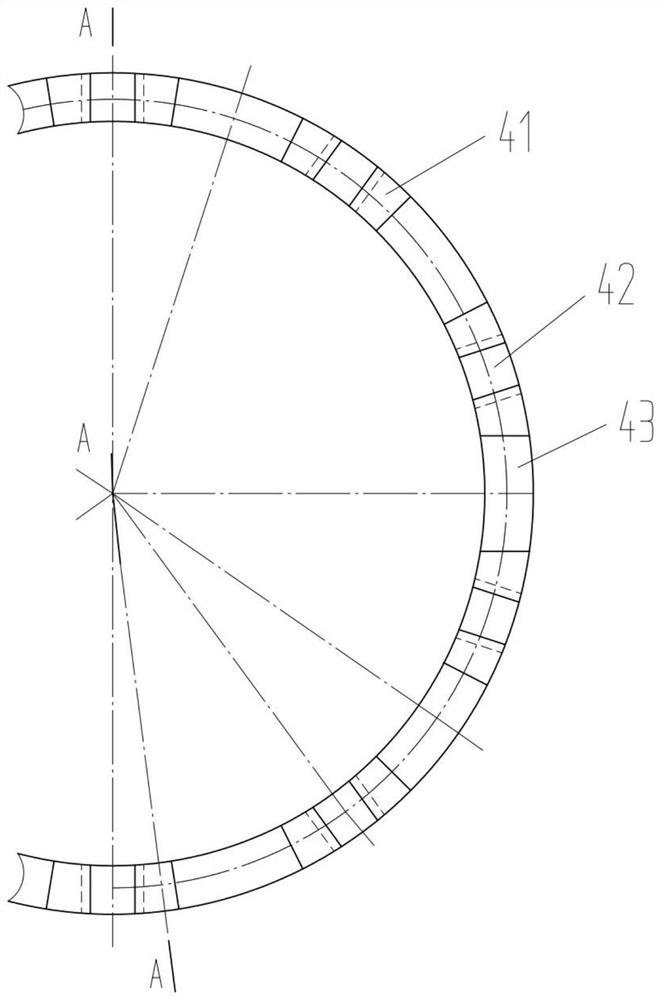

[0029] Object of the present invention is to provide a thin-walled positive section robot bearing, to solve the problems of the prior art, on the outer wall of the inner ring and the inner wall of the outer ring are respectively opened for ball rolling raceway, the contact part of the raceway and the ball symmetrically set on both sides of the mid-vertical line, and the contact angle is set to greater than 30 °, can increase the bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com