Side parting injection mold with dog-leg cams

A lateral parting and injection mold technology, applied in the field of lateral parting injection molds, can solve problems such as inapplicability of plastic parts with side holes or undercuts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below through specific implementations:

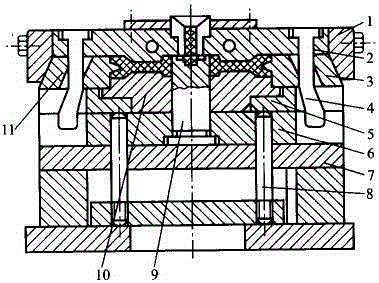

[0011] The reference signs in the drawings of the specification include: locking block 1, fixed template 2, first sliding block 3, bending pin 4, pusher plate 5, fixed plate 6, backing plate 7, push rod 8, core 9, Die 10, second slider 11.

[0012] The embodiment is basically as attached figure 1 Shown: a side parting injection mold with bending pins, the fixed template is set horizontally, the upper side of the fixed template is provided with a sprue sleeve, and the lower two sides of the fixed template are respectively provided with lower bending pins that are bent outward. There is a cooling water channel on the fixed template.

[0013] A first sliding block, a second sliding block, a concave mold, a pusher plate, a fixing plate, a backing plate, a guide sleeve and a mounting plate are sequentially arranged under the fixed template. The upper part of the concave mold is pr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap