An all-weather all-season tire tread structure

An all-season tire and all-weather technology, applied in tire tread/tread pattern, tire parts, transportation and packaging, etc., can solve problems such as high rolling resistance, single-sided performance, and insufficient snow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

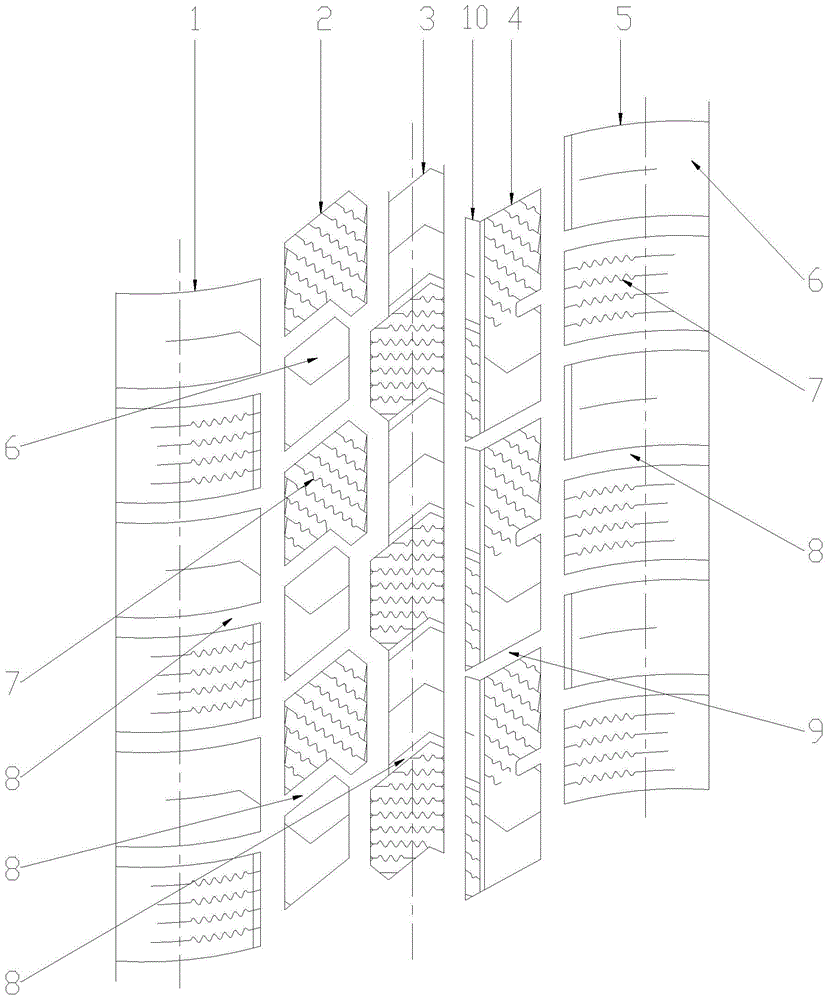

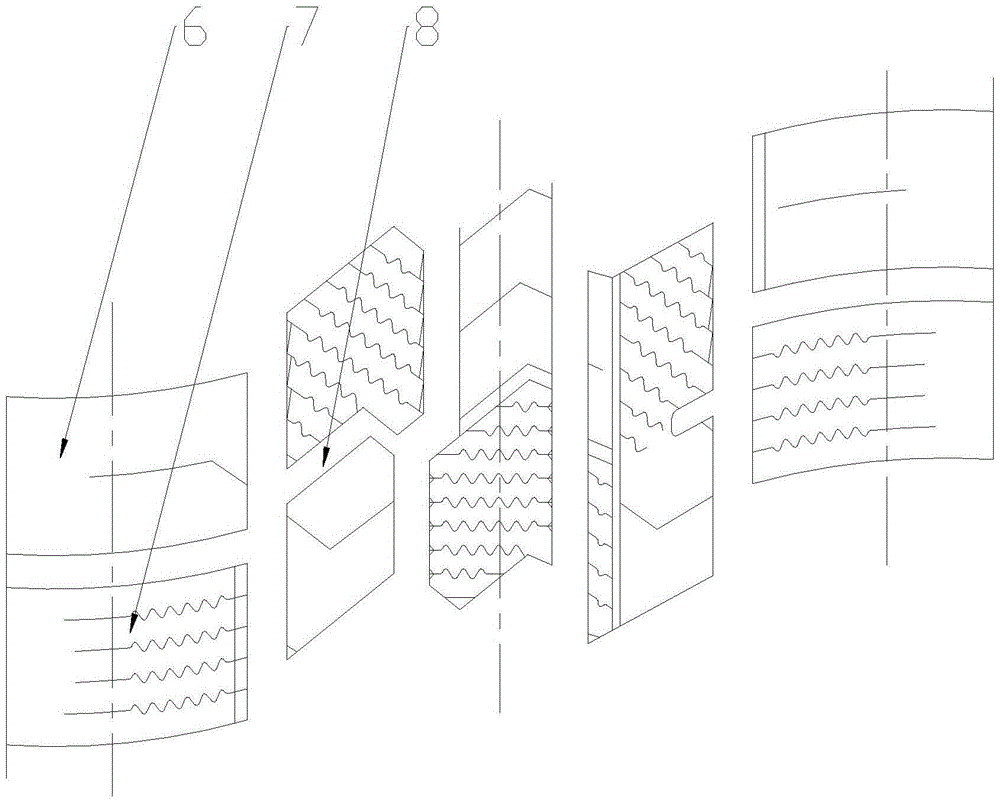

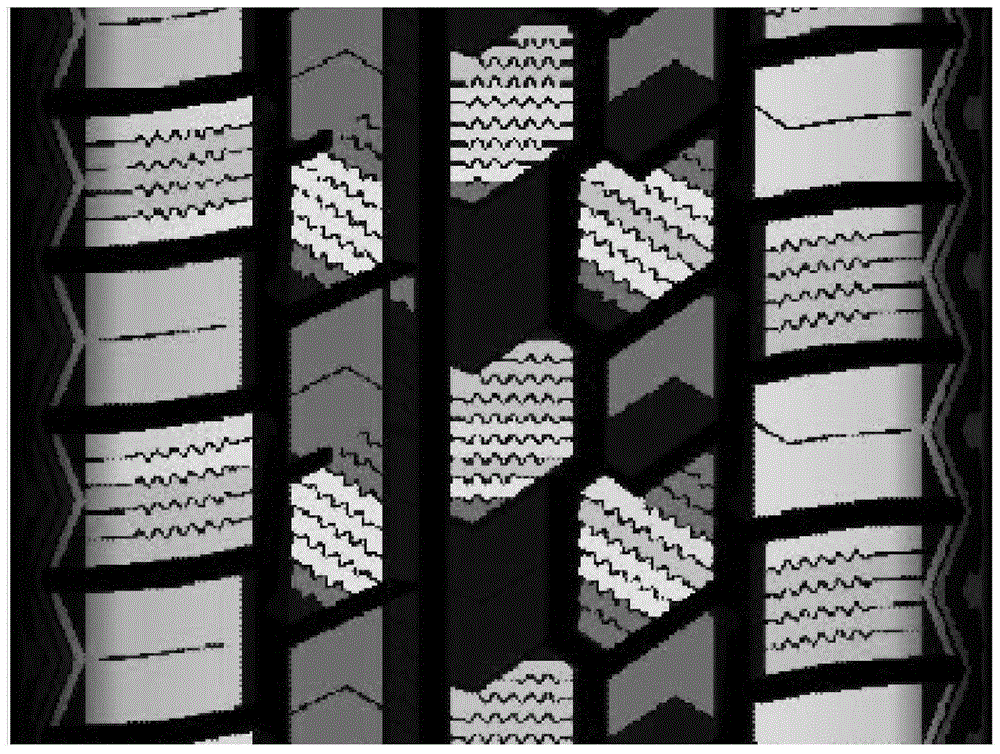

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] like figure 1 and figure 2 As shown, an all-weather four-season tire tread structure is mainly composed of repeated pitches, and each pitch is arranged in sequence by unit I1, unit II2, unit III3, unit IV4, and unit V5. The floor pattern blocks 6 and the wet floor pattern blocks 7 are alternately distributed, and the dry floor pattern blocks 6 and the wet floor pattern blocks 7 are also alternately distributed between every two adjacent units in the horizontal direction, and some of them are misplaced. Therefore, each type of pattern block corresponds to two types of pattern parts, which can better balance the two performances.

[0024] Further, the dry floor pattern block 6 is a smooth surface.

[0025] Further, the wetland pattern blocks 7 are horizontal corrugated long and narrow grooves or oblique corrugated long and narrow grooves. The angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com