Knitted fabric, method for producing a knitted fabric, and warp knitting machine

一种针织物、经编机的技术,应用在针织物领域,能够解决运行消耗大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

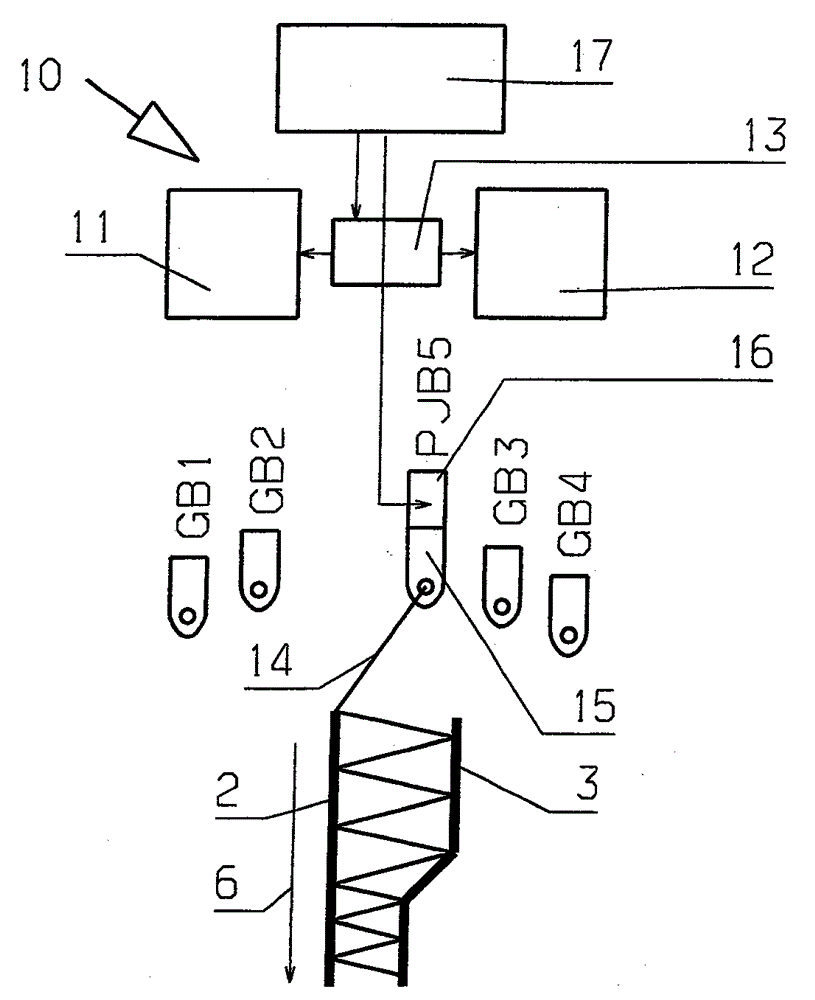

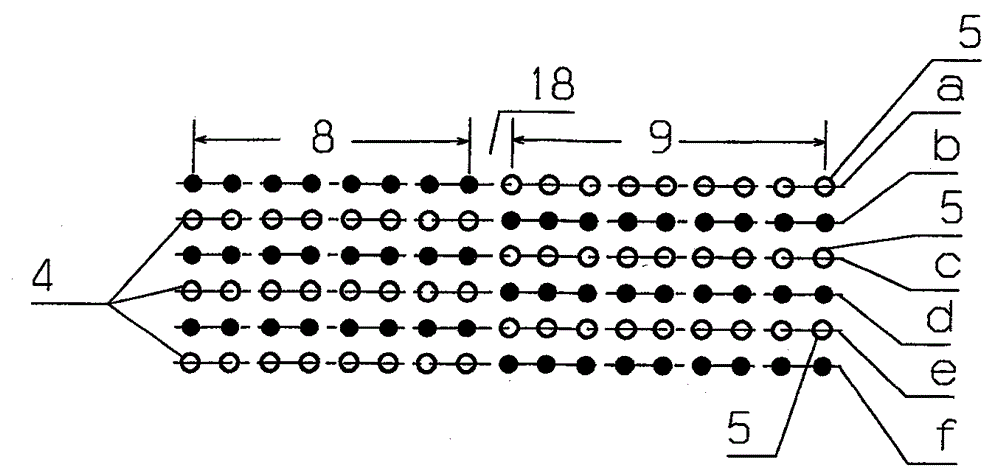

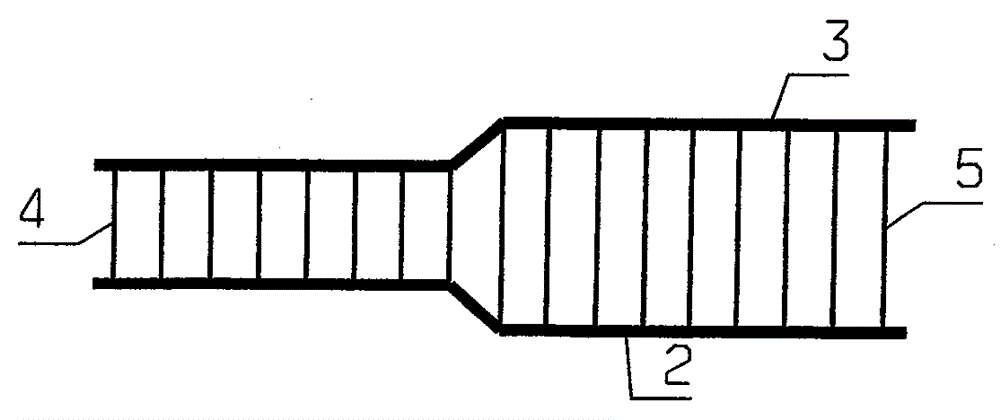

[0031] exist figure 1 The knitted fabric 1 shown in has a first cover layer 2 and a second cover layer 3 . Spacer threads 4,5 are arranged between the two cover layers 2,3. The spacer yarns are pile yarns, which interconnect the covering layers 2, 3. The spacer threads 4, 5 are thus woven into the two covering layers. The production direction 6 is also shown by arrows for explanation. The width direction 7 depicted by the double arrow extends transversely to the production direction 6 . It can be seen that the knitted fabric 1 has a first width region 8 with a smaller thickness and a second width region 9 with a larger thickness in the width direction. In the embodiment described here the first width region 8 has a thickness of 3 mm, while the second width region 9 has a thickness of 5 mm.

[0032] figure 2 A sectional view through the knitted fabric 1 is shown. The same elements are provided with the same reference signs.

[0033] It would be desirable to be able to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com