Component of rolling-element bearing and method for manufacturing the same

A technology for rolling bearings and rolling elements, which is applied in the direction of rolling contact bearings, roller bearings, rotating bearings, etc., and can solve problems such as shortened service life of bearings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In the following description of the drawings, the same reference numerals denote the same or similar components. Furthermore, summative reference signs are used for those parts and objects that appear several times in the exemplary embodiments or in the drawings, but are generally described with respect to one or more features thereof. Components or objects denoted with the same or collective reference signs can be implemented identically with regard to single, multiple or all technical features, for example with respect to their dimensions, but can also be implemented differently, as long as it is not clear from the description Get different express or implied.

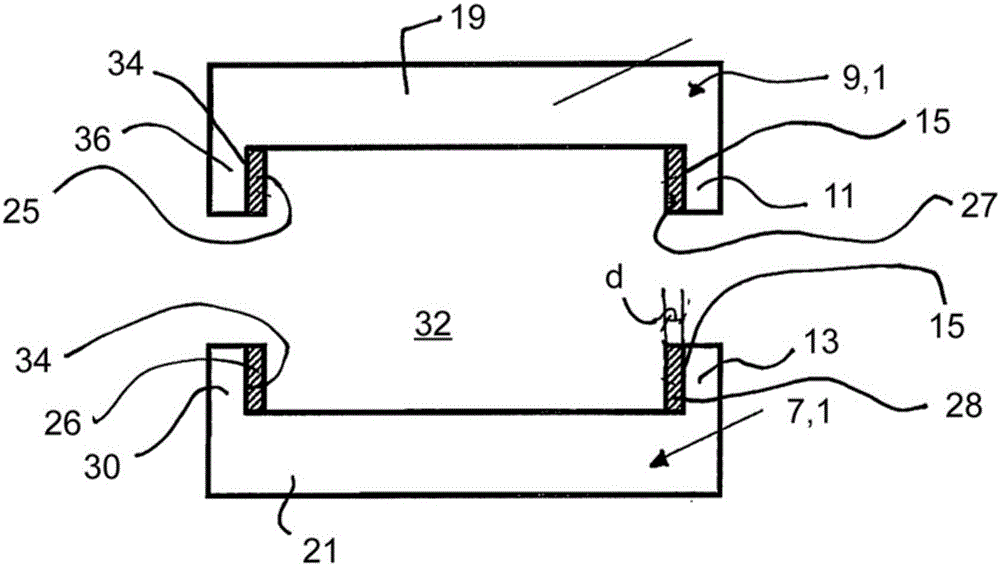

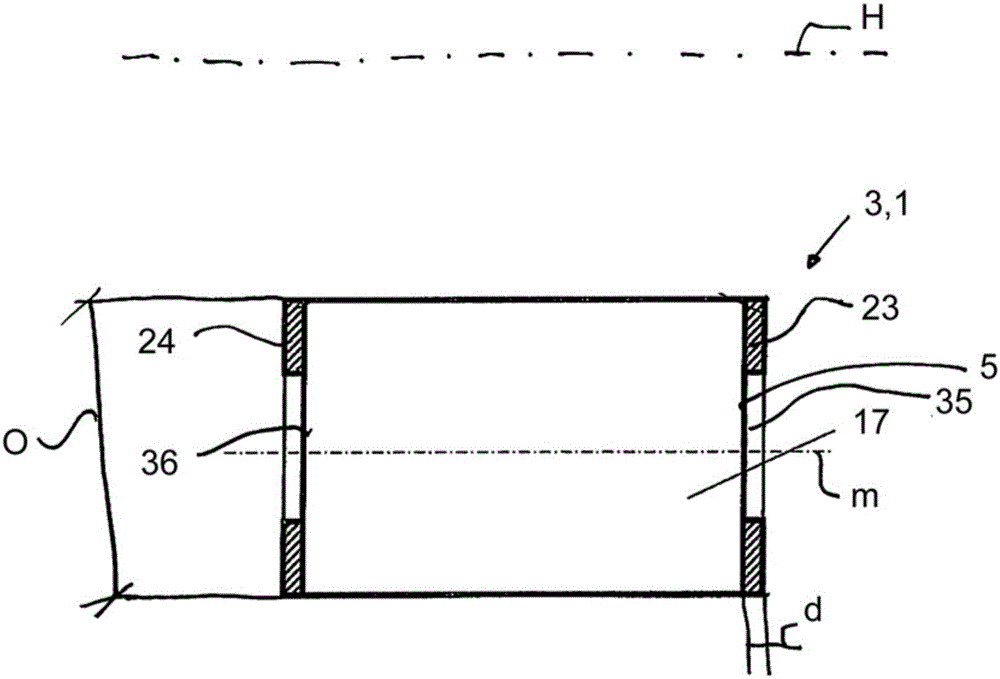

[0030] figure 1 A schematic diagram showing a cross-section of an outer ring and an inner ring as a device for a rolling bearing according to an exemplary embodiment of the invention.

[0031] figure 1 A device 1 for rolling bearings is shown. A rolling bearing comprises at least one rolling element 3, for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com