Sliding member for chain system, chain guide, chain tensioner and chain system

A sliding piece and chain technology, applied in transmissions, engine components, belts/chains/gears, etc., can solve problems such as large frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0046] The present invention will be better understood by referring to the following examples compared with comparative examples; but these examples are only for explaining the present invention and not limiting the scope of the present invention.

example 1

[0048] Electron beams (boosted voltage: 2 MeV) were irradiated to the molded powder of tetrafluoroethylene at an irradiation dose of 100 kGy in an environment having an oxygen partial pressure of 133 Pa and a nitrogen partial pressure of 106657 Pa under heating conditions of 350° C. (available from Asahi Glass Co., Ltd. under the trade designation G163), thereby improving the molding powder of tetrafluoroethylene. Thereafter, the modified molding powder was pulverized with a jet mill to have an average particle size of 25 μm, thereby obtaining a modified tetrafluoroethylene powder.

[0049] Subsequently, 20 parts by weight of the above-mentioned improved tetrafluoroethylene powder and 80 parts by weight of PA (polyamide) 66 resin (available from Asahi Kasei Chemicals Co., Ltd. under the trade name Leona 1402) with a number average molecular weight of 20000 Mix together to form a mixture. The mixture was injected into a twin-screw extruder through a feed hopper to complete gra...

example 2

[0053] 20 parts by weight of the improved tetrafluoroethylene powder in Example 1 and 80 parts by weight of PA (polyamide) 66 resin (available from Asahi Kasei Chemicals Co., Ltd. under the trade name Leona1402) with a number average molecular weight of 20000 Mix to form a mixture. The mixture was injected into a twin-screw extruder through a feed hopper to complete granulation so as to produce pellets, wherein the temperature of the twin-screw extruder was set at 290° C. and the rotation speed of the screw was 300 rpm.

[0054] Subsequently, the pellets formed by the twin-screw extruder were subjected to injection molding under the same conditions as in Example 1, whereby a slider (sample) of this example was obtained.

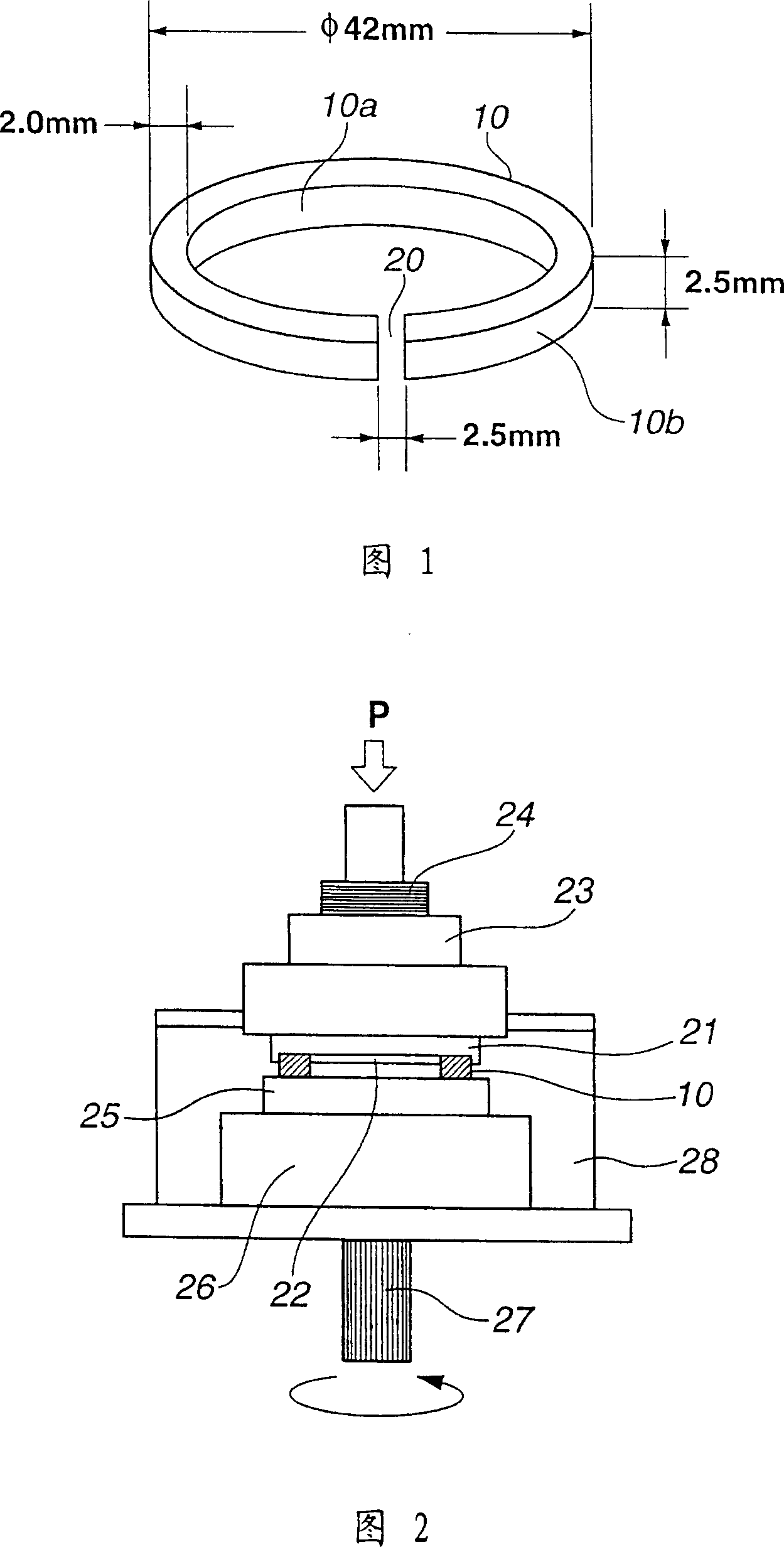

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com