Aluminum alloy section bar frame

A technology for aluminum alloy profiles and frames, applied in the field of aluminum alloy profiles, can solve problems such as cumbersome processes, achieve the effect of convenient installation and disassembly, and save the design process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

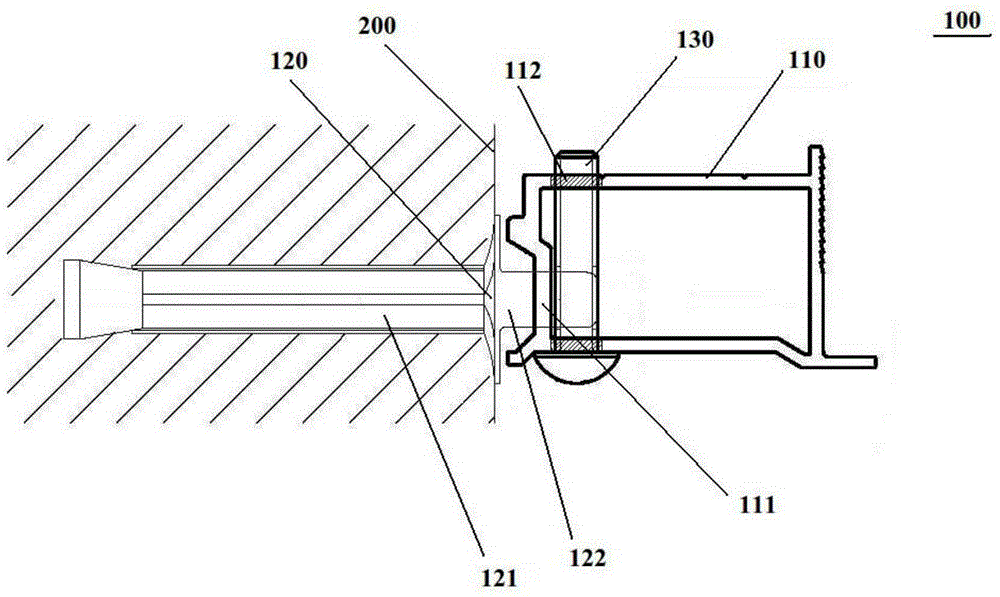

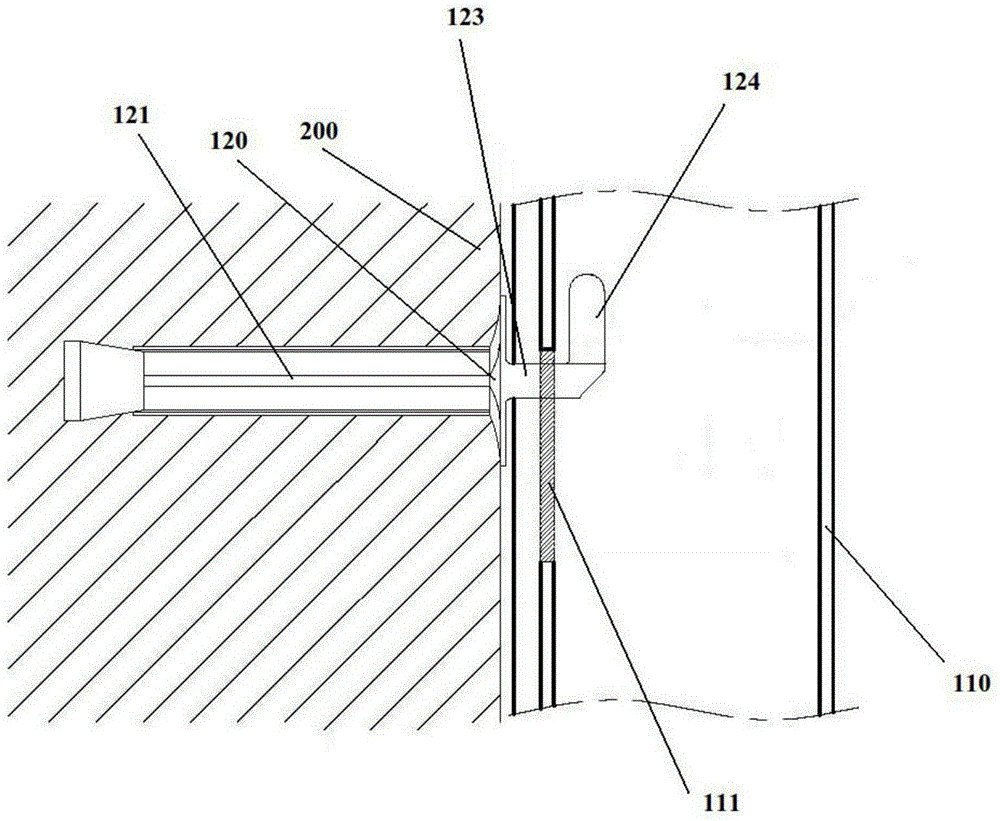

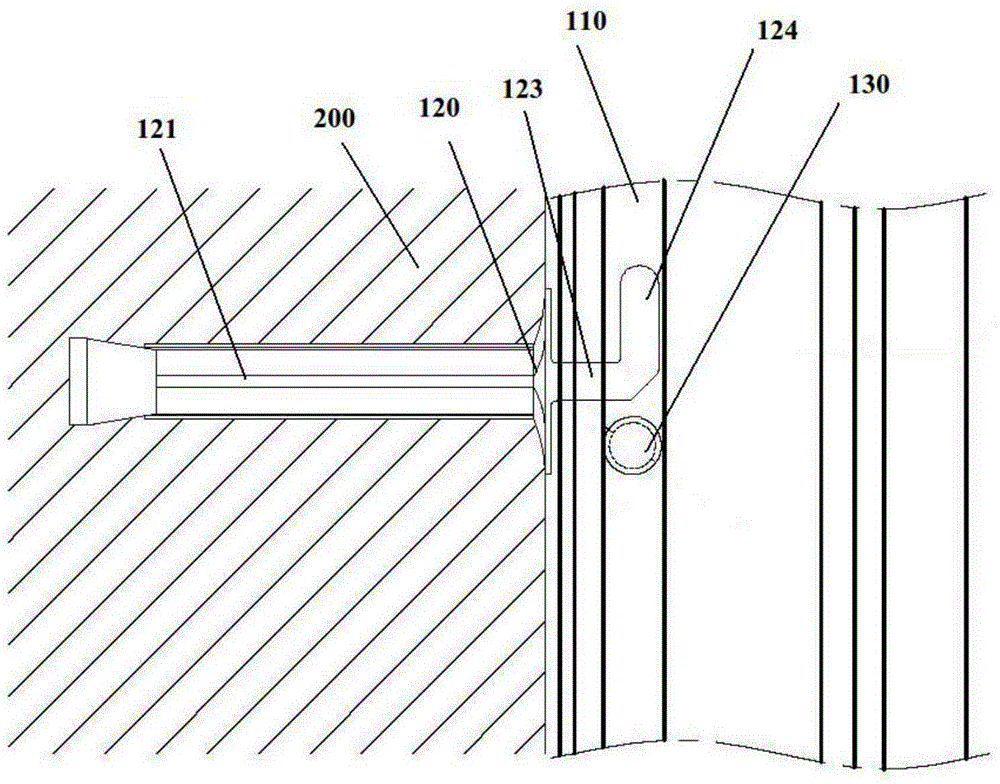

[0045] refer to Figure 1 to Figure 3, respectively show a side view, a top view and a bottom view of the installation structure 100 of a single aluminum alloy profile in a preferred embodiment of the present invention. Installed on the installation surface 200 that needs to be specified, such as walls, ceilings or outdoors, etc., the profile body 110 and the installation part 120 constitute the installation structure 100 in this embodiment. Specifically, the installation part 120 includes interconnected fixing parts 121 and installation The fixing part 122 and the fixing part 121 can be fixedly connected with the installation surface 200 by means such as drilling installation, so that the position of the installation part 120 on the installation surface 200 is fixed, and the installation part 122 is mechanically connected wi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap