Humidifier water tank and humidifier with humidifier water tank

A technology for humidifiers and water tanks, applied in air humidification systems, heating methods, household appliances, etc., can solve the problems of complex water tank space, difficulty in mold release, etc., and achieve the effect of increasing the amount of humidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

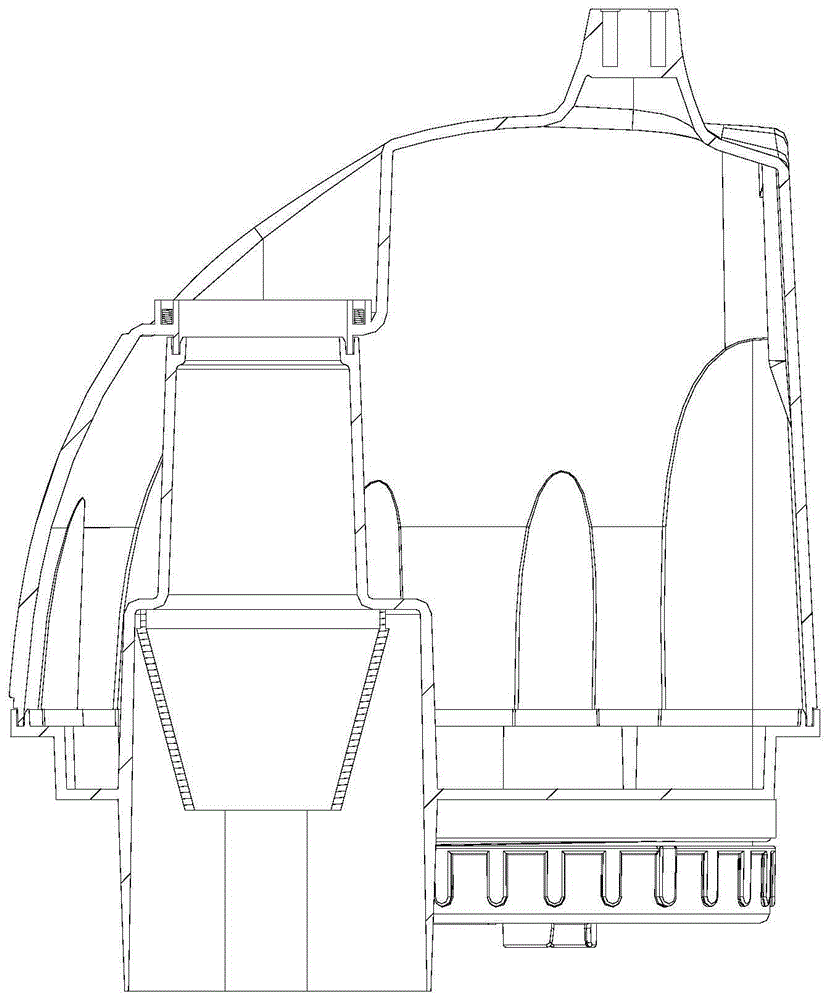

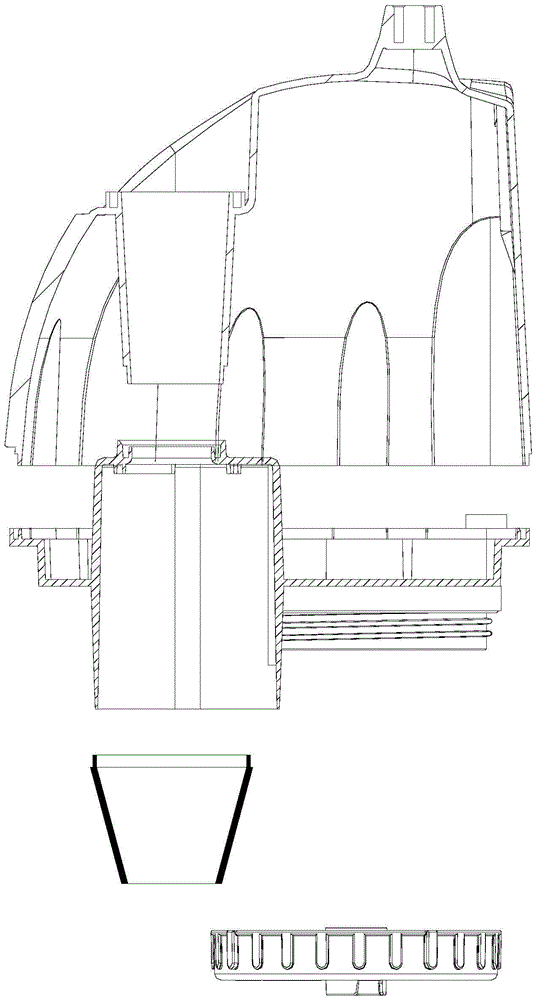

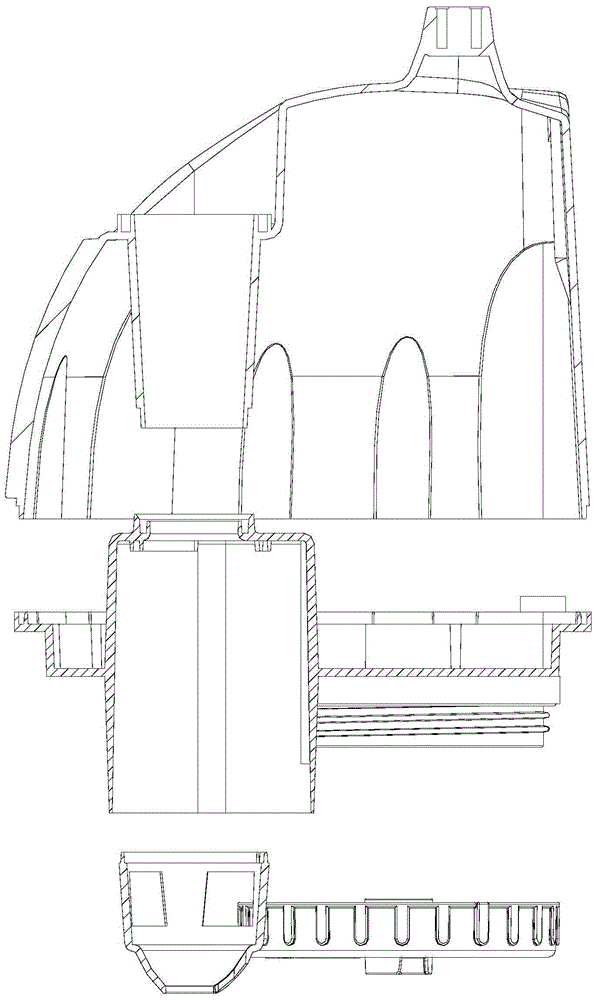

[0035] like Figure 1-3 As shown in , it shows a typical structural schematic diagram of humidifier water tanks commonly used in the market at present, and these water tanks all use non-detachable mist outlet pipe structures. in, Figure 1-2 The mist outlet pipe of the humidifier water tank is integrally formed with the bottom cover of the water tank. image 3 The mist outlet pipe of the humidifier water tank is integrally formed with the water tank shell. Water tanks using these types of mist outlet pipes generally have the problems of difficult mold release as mentioned above, the size of the mist outlet pipe is limited by the space size and molding process, and it is also prone to problems due to the installat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com