A wire connecting fitting

A wire connection and hardware technology, applied in the installation of electrical components, cables, overhead installation, etc., can solve the problems of easy loosening, insufficient connection, time-consuming and laborious installation, etc., to achieve firm connection, convenient operation and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

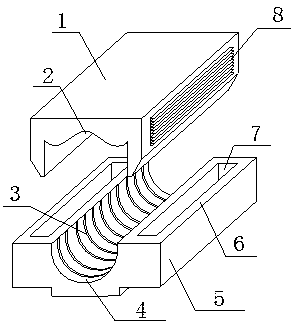

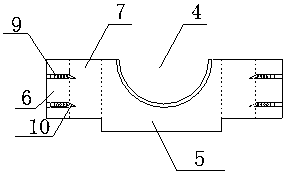

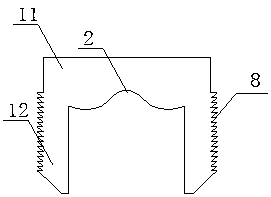

[0021] Such as figure 1 , figure 2 , image 3 As shown, a wire connection fitting includes a base 5 and a clamping plate 1. The clamping plate 1 includes a beam portion 11 and two vertical inserting plates 12 fixedly connected to both sides of the beam portion 11; the beam portion 11 is provided with The first trunking 2, the inner wall of the first trunking 2 is provided with some non-slip stripes 3 perpendicular to the central axis of the wire to be connected; the bottom of the vertical board 12 is inclined, and the outer surface of the vertical board 12 is provided with Detent 8; the base 5 is provided with a second wire slot 4, the inner wall of the second wire slot 4 is provided with a number of anti-slip stripes 3 perpendicular to the central axis of the wire to be connected, and a lock slot 7 is respectively arranged on the two side walls of the second wire slot 4 ; The lock groove wall 6 is provided with a number of elastic component installation holes from top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com