Boring processing method of super-long circuit board

A processing method and circuit board technology, applied in the directions of printed circuit, printed circuit manufacturing, PCB positioning during processing, etc., can solve the problems of long production cycle, high equipment cost, complex process, etc., to reduce equipment cost and improve production. Efficiency and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

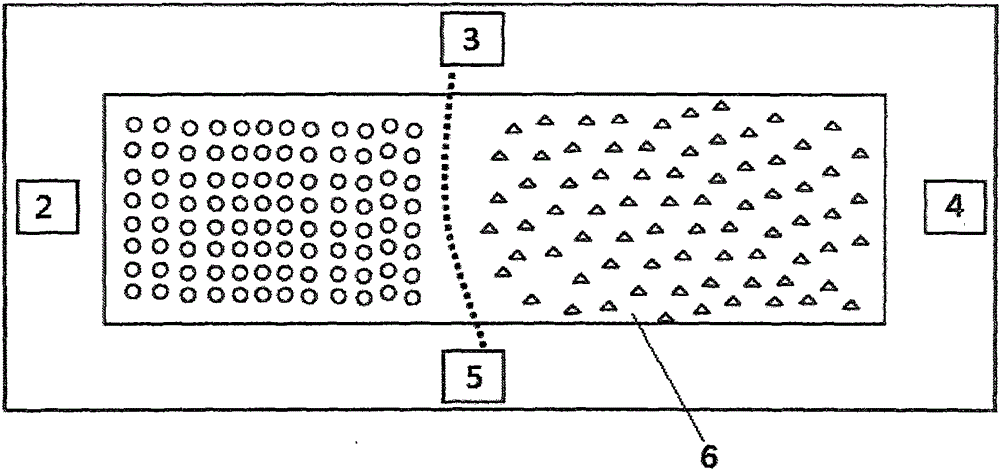

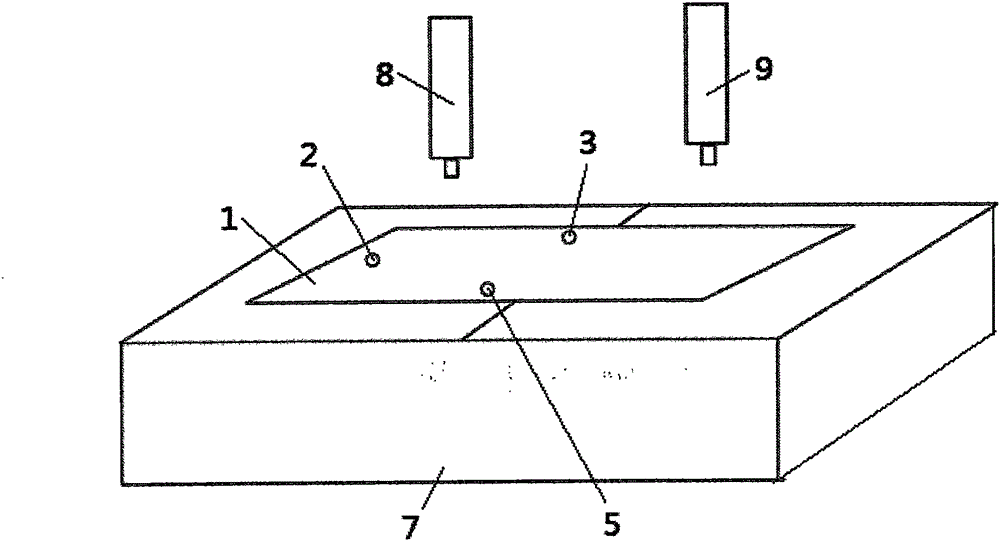

[0018] Please refer to Figure 1 to Figure 4 , the invention provides a method for drilling ultra-long circuit boards, comprising:

[0019] Step 1, such as figure 2 As shown, the first positioning hole 2, the second positioning hole 3, the third positioning hole 4 and the fourth positioning hole 5 required for drilling are drilled on the circuit board 1 using an X-ray target machine. The circuit board 1 includes an effective pattern area 6. The first positioning hole 2, the second positioning hole 3, the third positioning hole 4 and the fourth positioning hole 5 are set corresponding to the four sides of the circuit board 1 and located outside the effective graphic area 6, and the first positioning hole 2 It is set opposite to the third positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com