Drum washing machine

A drum washing machine and drum technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of reduced cleaning performance and reduced mechanical force of laundry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039]Hereinafter, a drum washing machine without a drying function as an embodiment of the drum washing machine of the present invention will be described with reference to the drawings.

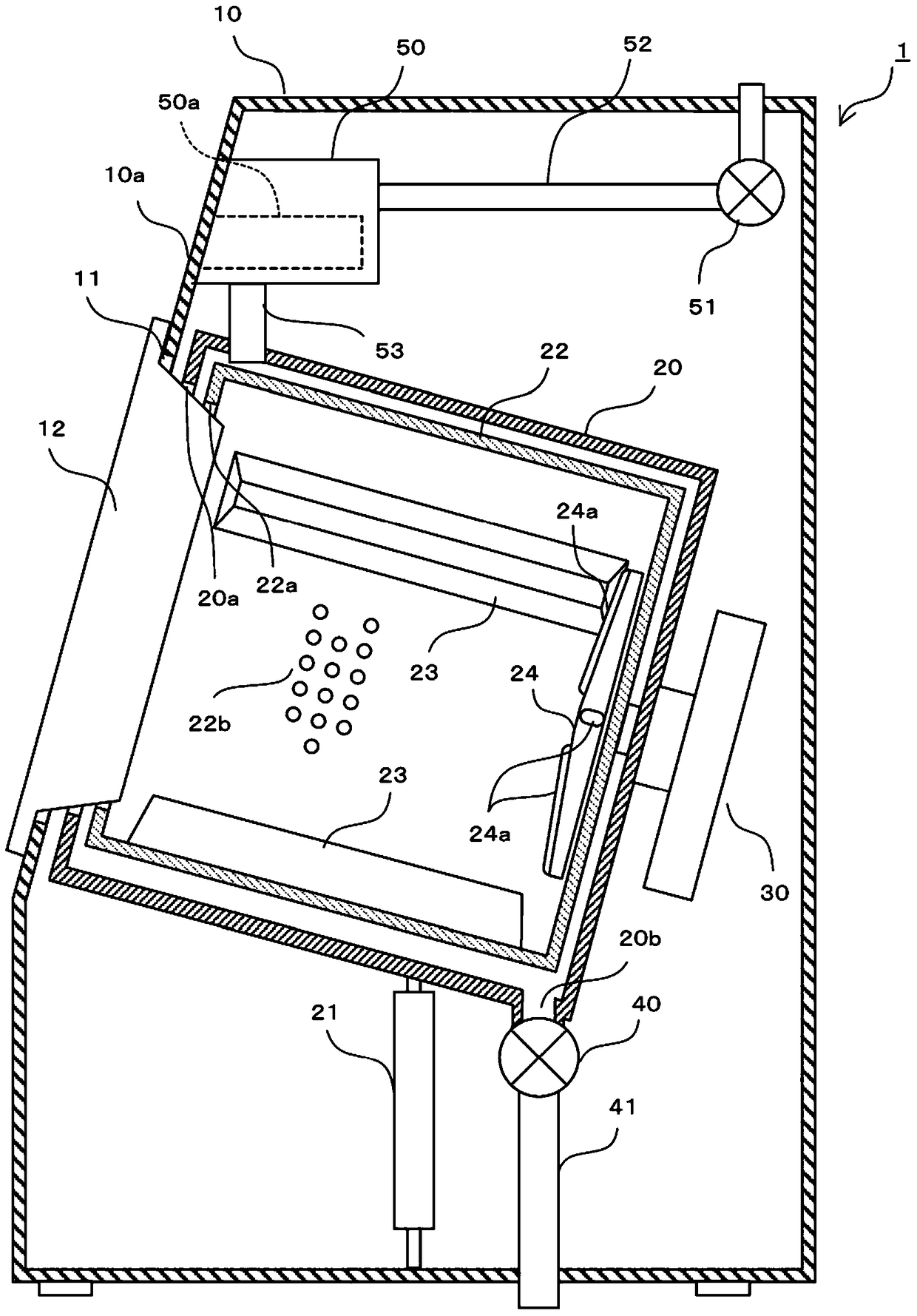

[0040] figure 1 It is a side sectional view showing the structure of the front-loading washing machine 1 .

[0041] The drum washing machine 1 has a casing 10 constituting an appearance. The front surface 10a of the casing 10 is inclined upward from the central portion, and an inlet 11 for laundry is formed on the inclined surface. The inlet 11 is covered by an openable and closable door 12 .

[0042] Inside the housing 10 , the outer tank 20 is elastically supported by a plurality of dampers 21 . A drum 22 is rotatably arranged in the outer tank 20 . The outer tank 20 and the drum 22 are inclined so that the rear surface side is lowered with respect to the horizontal direction. Thereby, the drum 22 rotates centering on the inclined axis inclined with respect to the horizontal directio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap