A stirring plate for paint raw materials

A technology for mixing discs and raw materials, applied in mixer accessories, mixers, dissolving and other directions, can solve problems such as unreasonable structural design, uniform paint mixing, affecting enterprise benefits, etc., and achieve reasonable rotating shaft structure design, time saving, and operation steps. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

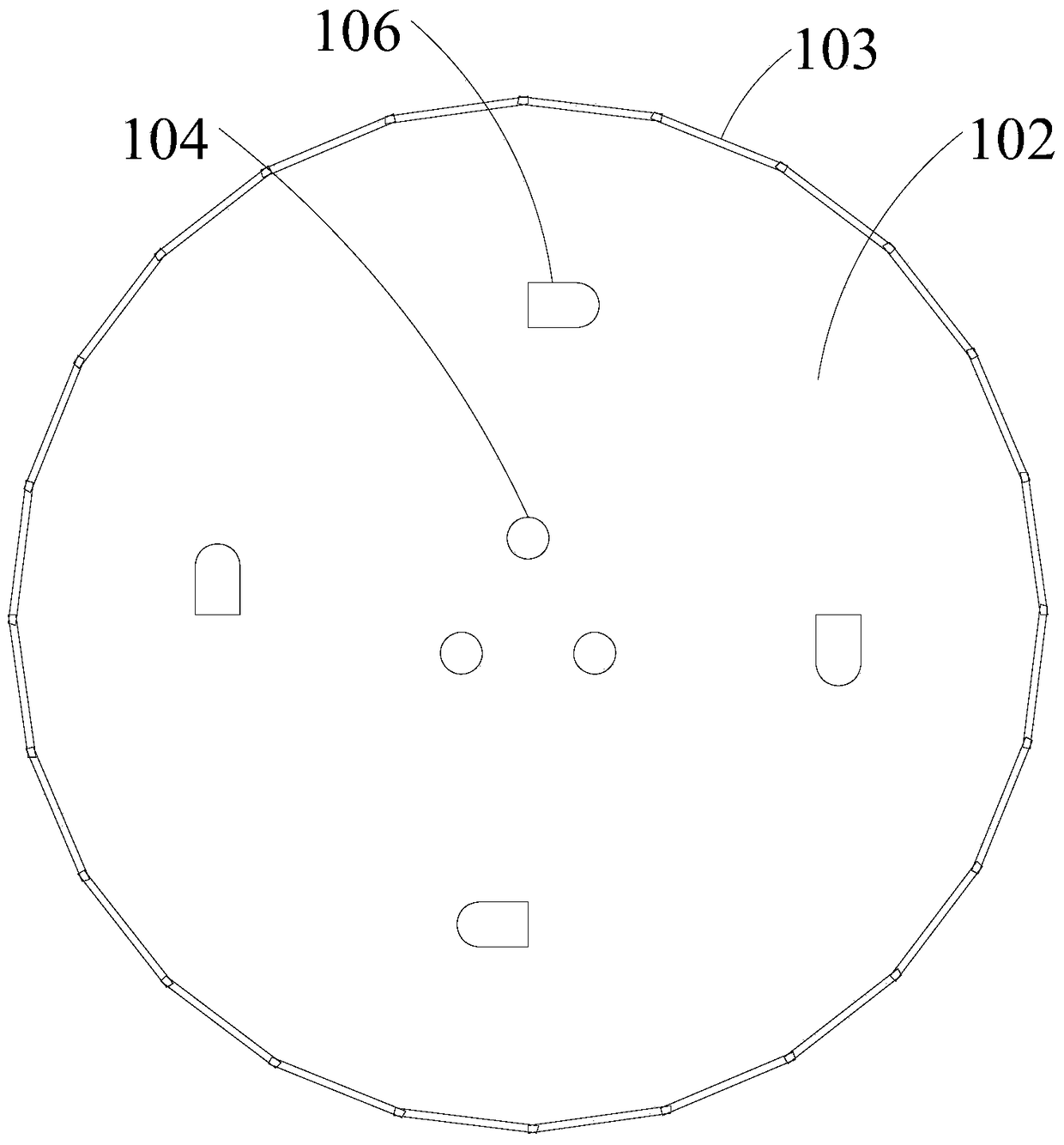

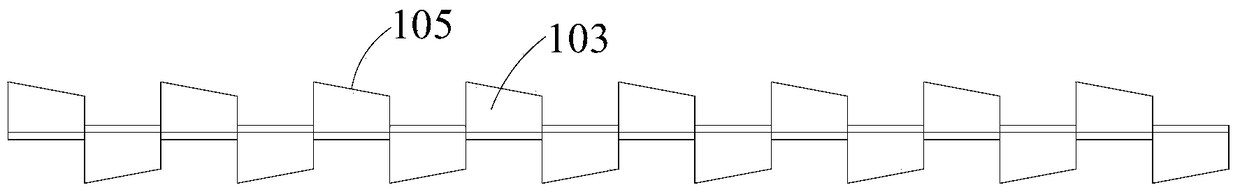

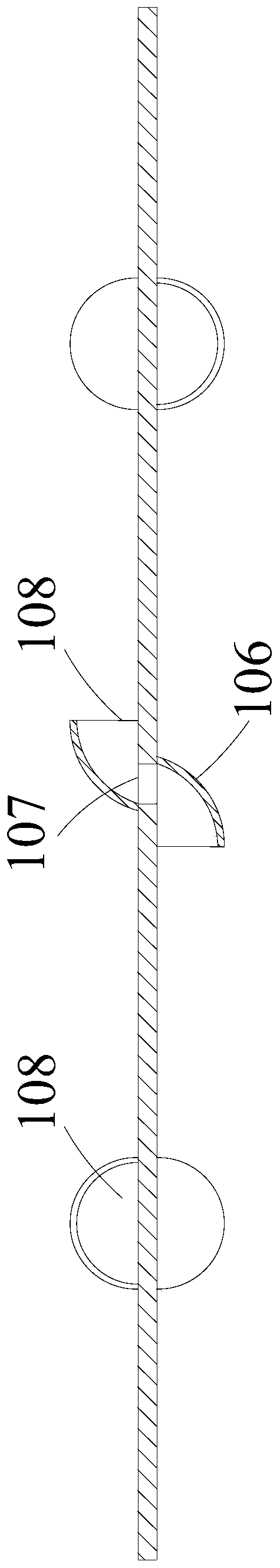

[0064]A paint raw material stirring plate, comprising a disc body 101, the disc body 101 includes a disc 102 and stirring teeth 103 connected to the edge of the disc 102; the disc 102 is provided with at least three installation holes 104, and all the installation holes 104 are arranged along the circle The axial direction of the disc 102 is distributed in a ring; there are multiple stirring teeth 103, and the plurality of stirring teeth 103 are arranged adjacent to each other to form a ring-shaped set of teeth. The stirring teeth 103 are polygonal, and each stirring tooth 103 includes a relative bottom edge And the top edge 105, the stirring tooth 103 is connected with the disk 102 through the bottom edge, the top edge 105 of the stirring tooth 103 is arranged obliquely relative to the disk 102, and the lower end of the top edge 105 is located at the higher end along the rotation direction of the disk body 101. In front of one end of each two adjacent stirring teeth 103, one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com