Rotary steel pipe clamp capable of automatically arranging pipes

A rotary and management technology, applied in the direction of lifting devices, etc., can solve the problems of high labor intensity and low work efficiency, and achieve the effect of reducing labor intensity, not easy to fall, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

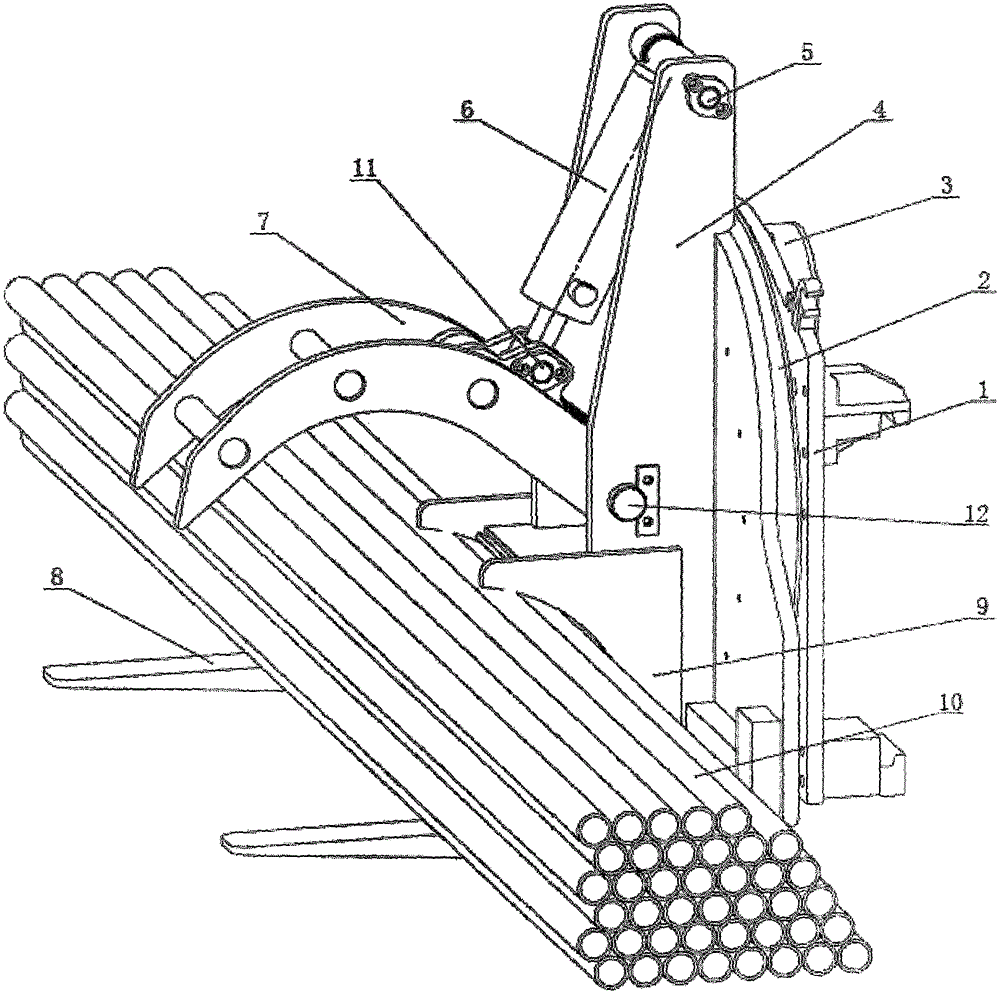

[0013] see figure 1 , a rotary steel pipe clamp for automatic management, including a rotating base 1, a rotating frame 4, pressing teeth 7 and a fork 8; A deceleration motor 3 that drives the rotating frame 4 to rotate is also installed. The slewing bearing 2 is an inner and outer ring structure, and its inner ring and outer ring are respectively connected to the rotating frame 4 and the rotating base 1, so that the rotating bearing 2 makes the rotating frame 4 and the rotating base 1 can rotate relative to each other, and the reduction motor 3 drives the rotating frame 4 to rotate around the rotating base 1. Preferably, the slewing bearing 2 and the reducing motor 3 are fixed on the rotating base 1 by bolts; the fork 8 is fixed on the rotating base 1. At the lower end of the frame 4, the pressing tooth 7 is rotated and installed in the middle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com