Extended contact area for leadframe strip testing

A lead frame, lead technology, applied in the direction of semiconductor/solid state device testing/measurement, etc., can solve problems such as problems, lead frame strip testing cannot be performed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

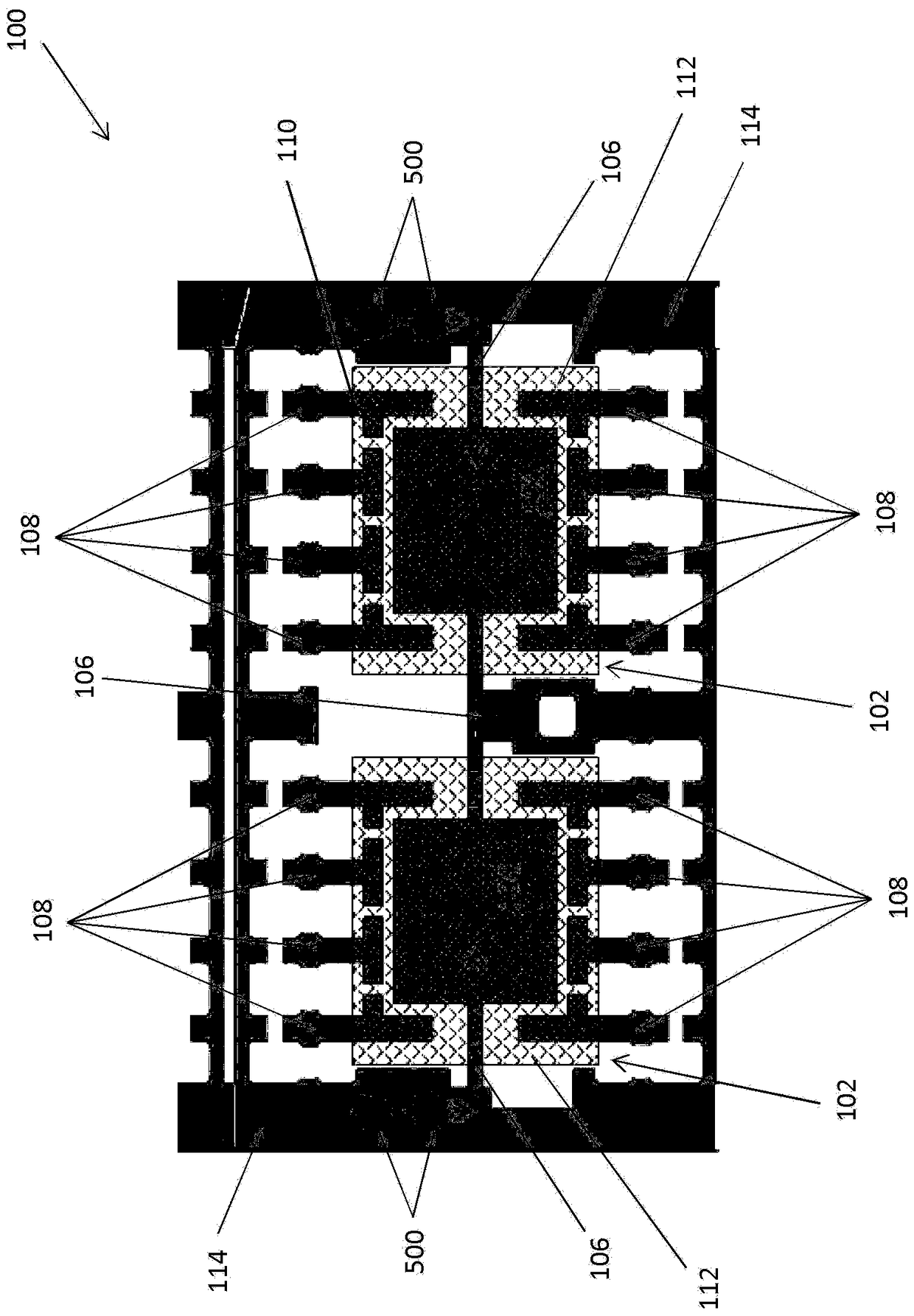

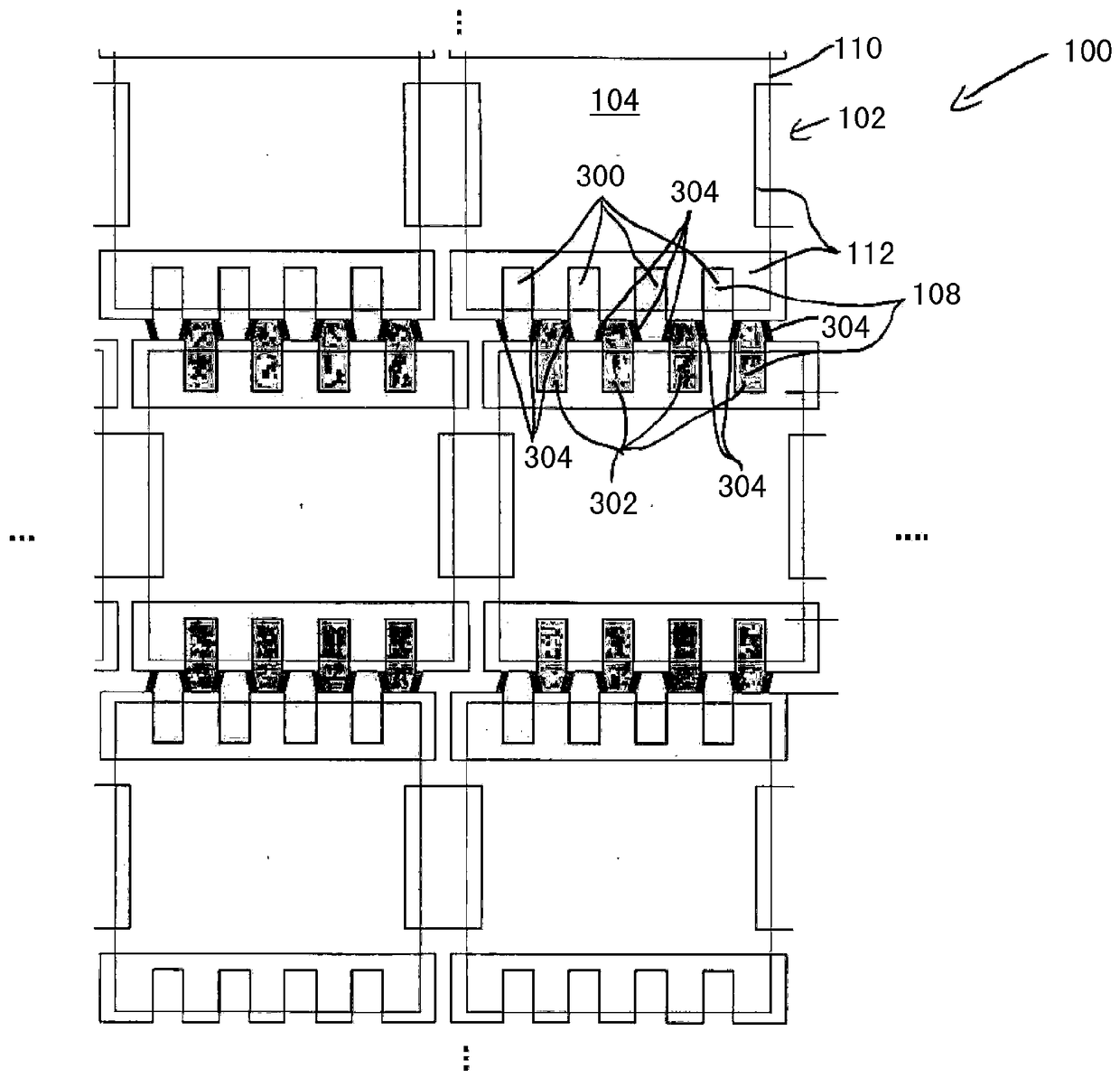

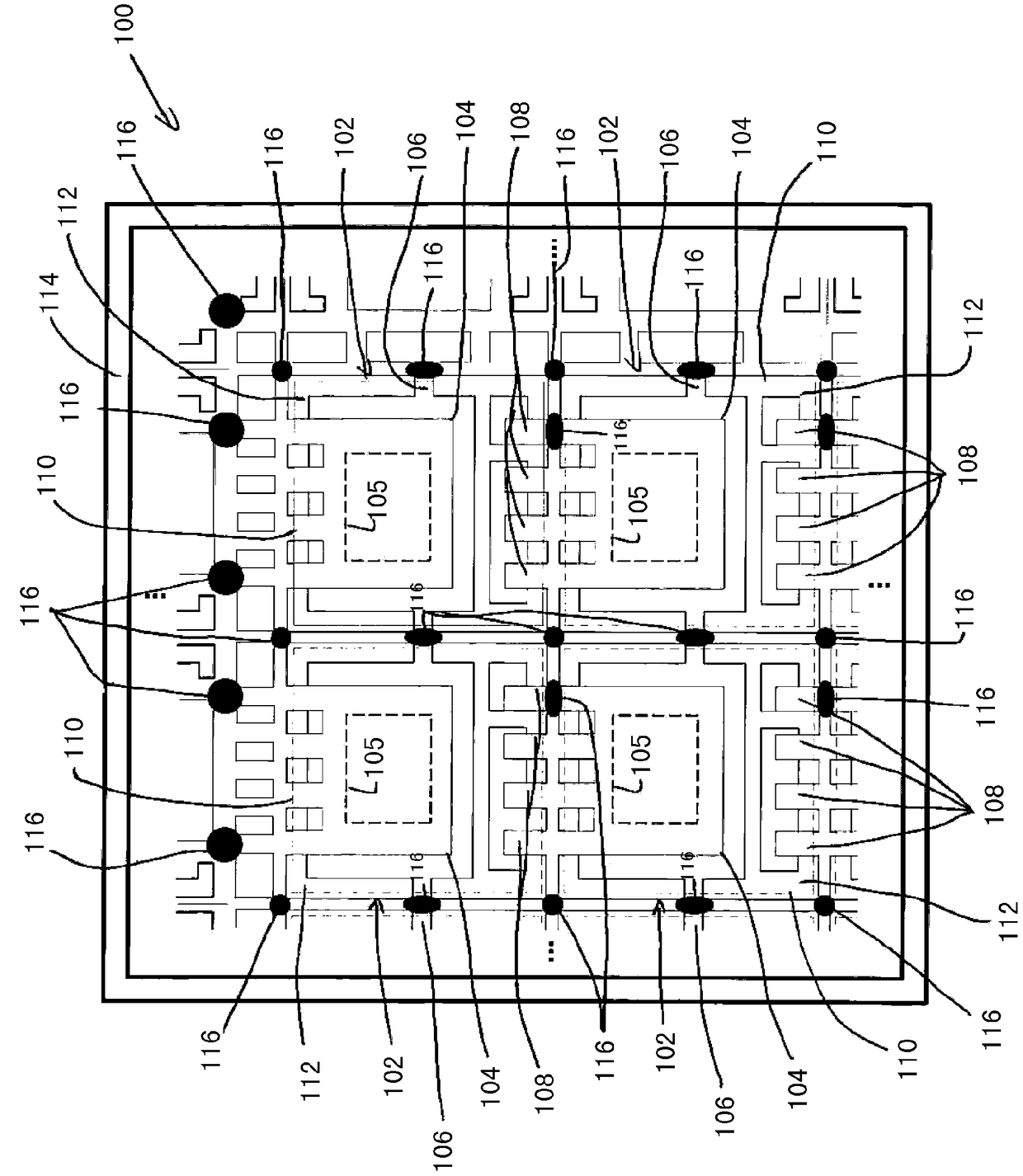

[0017] According to embodiments described herein, a leadframe strip includes a plurality of unit leadframes. At least the leads of the unit leadframe are electrically isolated from the perimeter of the leadframe strip prior to strip testing. After being electrically isolated from the perimeter of the leadframe strip, at least some of the leads extend uninterrupted beyond the final lead outline of the cell leadframe. Leads that extend uninterrupted beyond the final lead profile of the cell lead frame after the electrical isolation process have additional contact areas for test probing. In some cases, portions of the leads that extend uninterrupted beyond the final lead profile of the cell leadframe after the electrical isolation process are actually probed during the testing process. In other cases, leads with extended contact areas remain integrally connected to die paddles of adjacent cell leadframes during the testing process so that adjacent die paddles, rather than the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com