Buffer block oiling tooling

A buffer block and oiling technology, applied in the field of tooling and fixtures, can solve the problems of poor oiling effect, difficult control of oil quantity, uneven oil application, etc., and achieve good oiling effect, improve application efficiency, and uniform oil effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

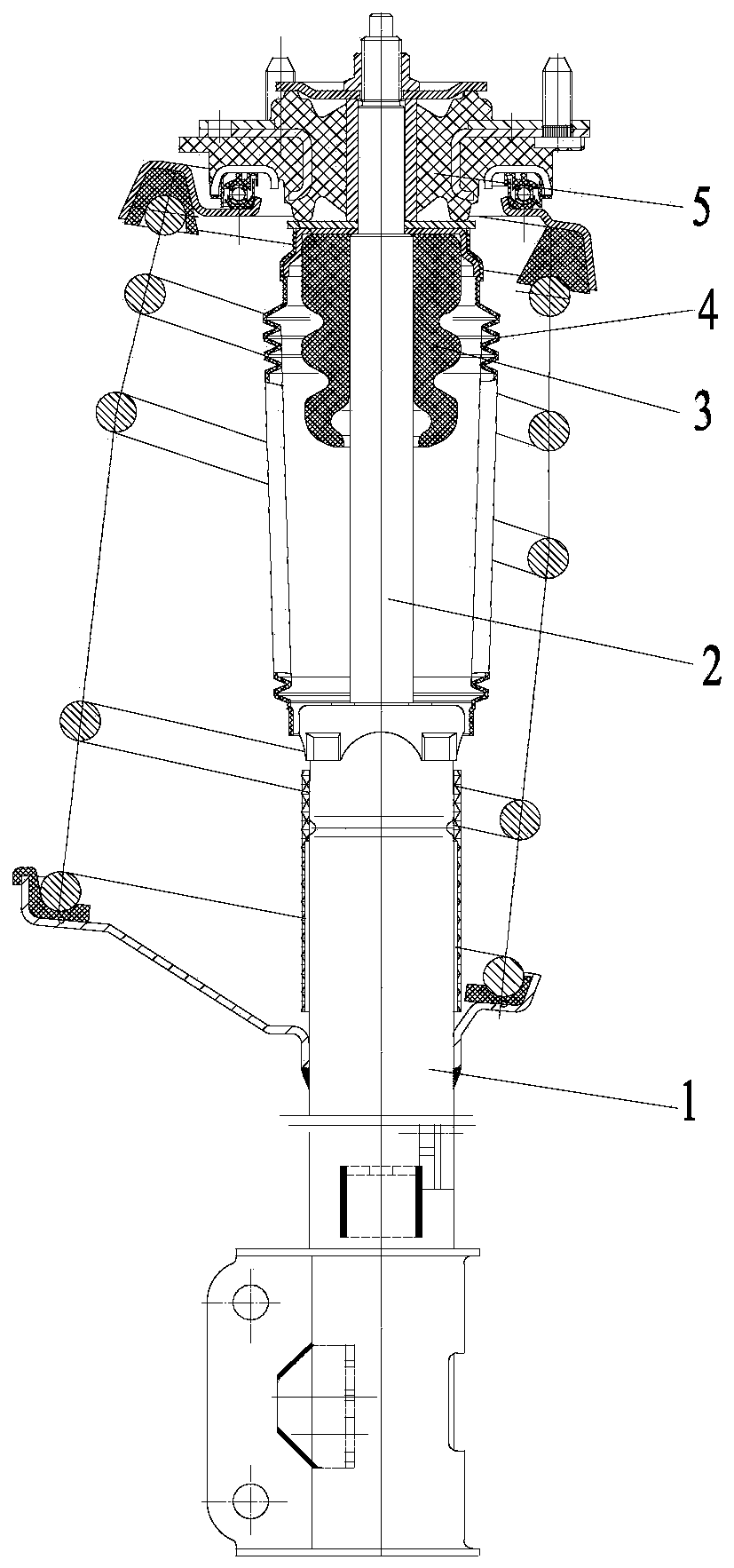

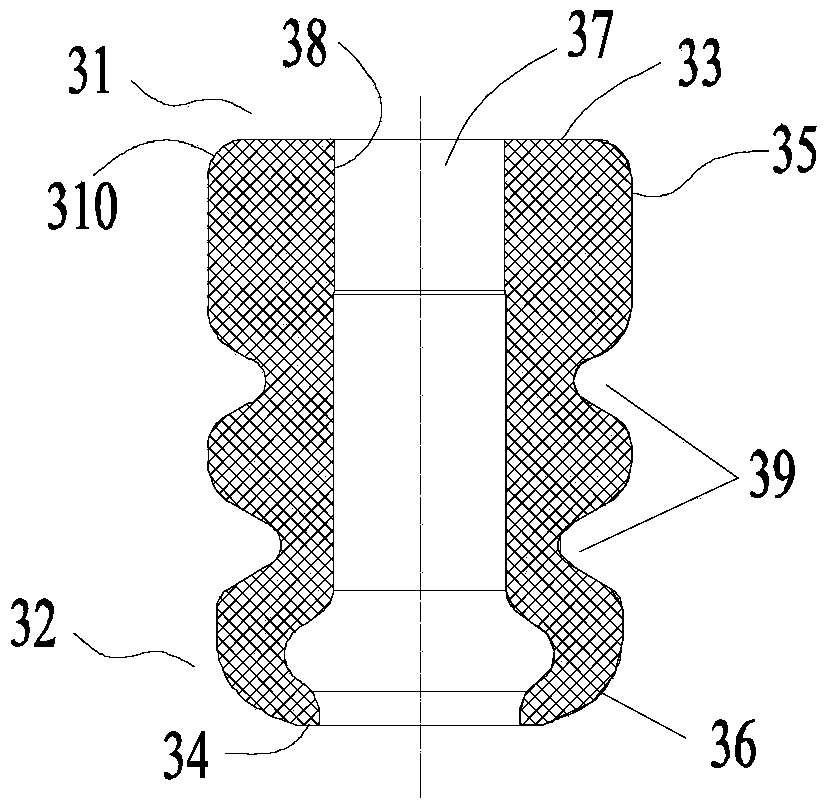

[0071] This embodiment provides a buffer block oiling method for such as figure 1 with figure 2 The cylindrical end 31 and the truncated conical end 32 of the shown buffer block are oiled, and the oiling method includes the following steps:

[0072] (1) Provide buffer block oiling tooling;

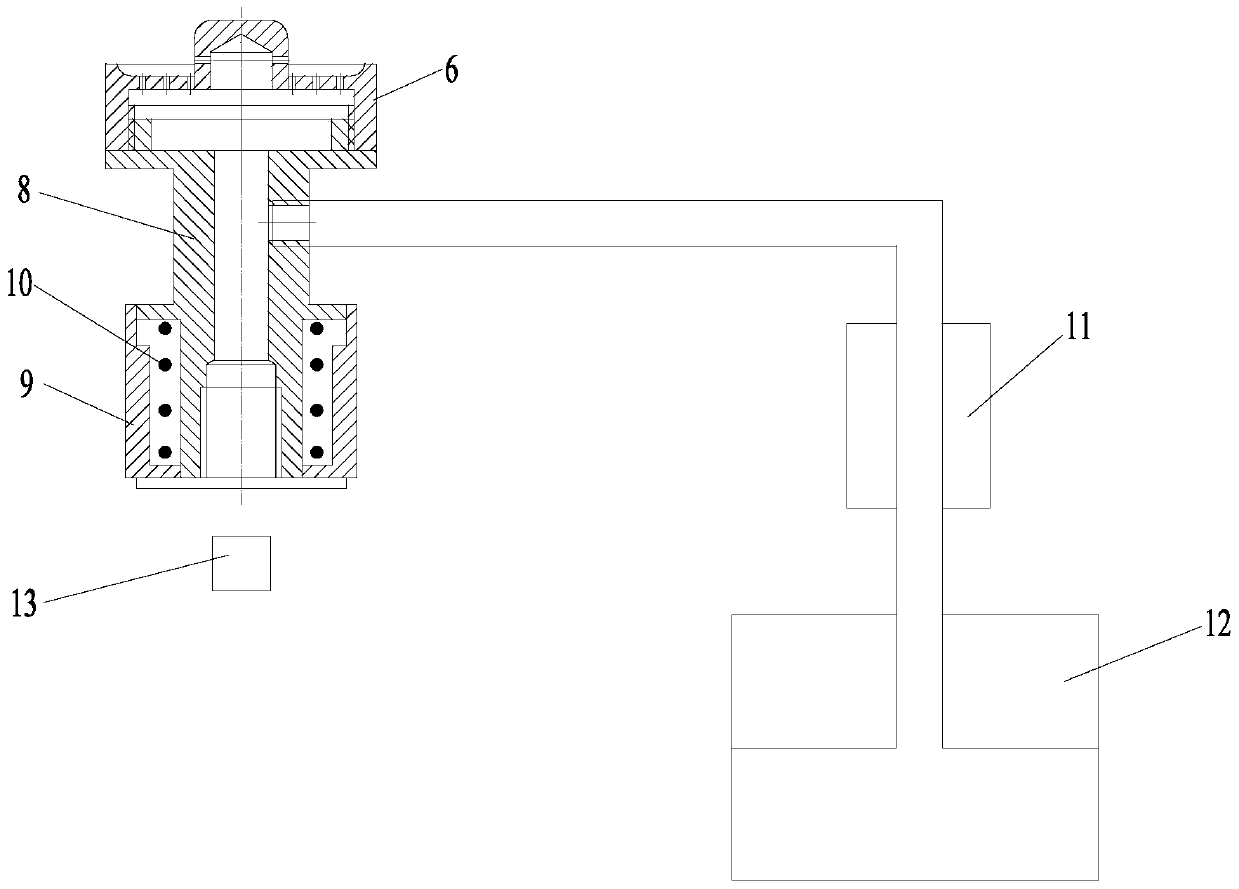

[0073] Install the first oil nipple 6 of the buffer block oiling tool on the protruding ring 83 of the oil nipple fixing seat 8, and tighten the first oil nipple 6.

[0074] (2) The buffer block is placed on the buffer block oiling tool, and the cylindrical end 31 of the buffer block is smeared with grease;

[0075] The specific process of step (2) is: place the buffer block in the first accommodation groove 67 of the first oil nozzle 6 with the cylindrical end 31 facing down, and insert the boss 62 into the central hole 37 of the buffer block , the buffer block is in a vertical state; then press the buffer block downwards, the buffer block pushes down the nozzle fixing seat 8 and the ...

Embodiment 2

[0080] This embodiment provides a buffer block oiling method for such as figure 1 with figure 2 The cylindrical end 31 and the truncated conical end 32 of the shown buffer block are oiled, and the oiling method includes the following steps:

[0081] (1) Provide buffer block oiling tooling;

[0082] Install the second oil nipple 7 of the buffer block oiling tool on the protruding ring 83 of the oil nipple fixing seat 8, and tighten the second oil nipple 7.

[0083] (2) The buffer block is placed on the buffer block oiling tooling, and the frustum-shaped end 32 of the buffer block is smeared with grease;

[0084] The specific process of step (2) is: place the buffer block in the second accommodation groove 74 of the second oil nozzle 7 with the truncated conical end 32 facing down, and the buffer block is in a vertical state; then press the buffer block downwards. block, the buffer block pushes down the oil nozzle fixing seat 8 and the second oil nozzle 7 on it, when the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com